Introduction

Heat sinks are an essential part of any electronic device to prevent overheating and potential damage. They are commonly used in laptops, smartphones, and computers to regulate heat emitted by the components. If you are planning to use a heat sink, it is crucial to understand What is required for heat sink? and how it works.

The Purpose of Heat Sink

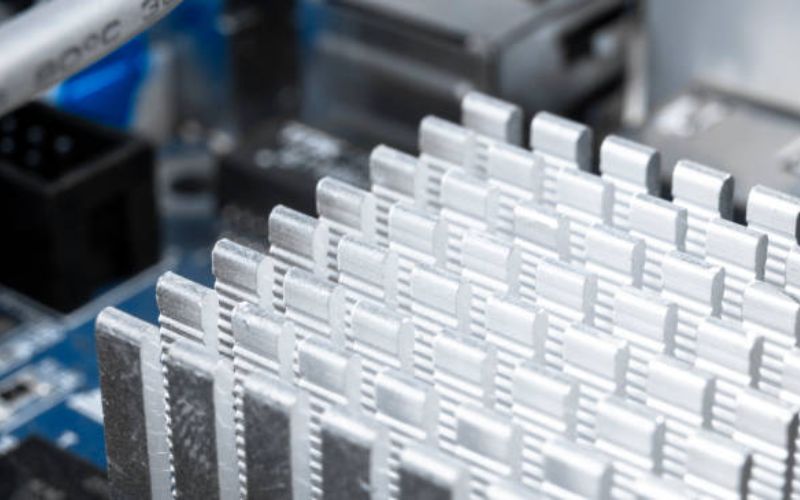

The primary function of a heat sink is to absorb, transfer, and dissipate heat generated by electronic components such as CPU, GPU, or power transistors. The two primary methods of heat transfer in a heat sink are conduction and radiation. A heat sink provides a larger surface area for air or liquid coolant to pass through and take away the heat generated by the components. Hence, a properly functioning heat sink will help maintain the optimal performance of the device and prevent damage caused due to overheating.

Materials Used for Heat Sink

The materials used for heat sink are critical to their performance. Typically, a heat sink is made of materials that have high thermal conductivity, corrosion resistance, and good mechanical properties. Common materials used include aluminum, copper, and their alloys. Copper is a more efficient heat conductor than aluminum, but it is more expensive. Aluminum is a popular choice as it is affordable, lightweight, and has excellent corrosion resistance. However, the choice of material may vary depending upon the application, the required performance, and the cost.

Design Considerations for Heat Sink

The design of the heat sink plays an essential role in its performance. The design of the heat sink should ensure maximum contact area between the heat-generating device and the heat sink to achieve minimum thermal resistance. The design should also provide a path for the dissipation of heat, such as fins or other surface enhancements. The shape and size of the heat sink are determined based on factors such as the heat generated, ambient temperature, and available space. A well-designed heat sink would also take into consideration the airflow through the device.

Installation of Heat Sink

The installation of the heat sink has a significant impact on its performance. It is essential to consider the orientation of the heat sink and the thermal paste or compound used between the heat sink and the electronic component. The thermal paste or compound improves the contact area between the two surfaces and helps in the transfer of heat. The thickness, consistency, and application of thermal paste must be optimal to ensure maximum performance. The mounting pressure while installing the heat sink should also be uniform for proper contact between the two surfaces.

Factors Affecting Heat Sink Performance

The performance of a heat sink can be affected by several factors, such as the ambient temperature, airflow, thermal resistance of the material used, and the surface finish of the heat sink. High temperatures can increase the thermal resistance of the material and decrease the efficiency of the heat sink. Inadequate airflow or obstruction can reduce the rate of heat dissipation. A rough surface finish can decrease the contact area and hence the efficiency of the heat sink.

Types of Heat Sinks

There are several types of heat sinks available in the market, each with its unique design and performance. Some common types include passive heat sinks, active heat sinks, liquid-cooled heat sinks, and heat pipes. Passive heat sinks are simple designs that rely on natural convection to dissipate heat. Active heat sinks include fans or blowers to create airflow and increase cooling performance. Liquid-cooled heat sinks use a liquid coolant to carry away heat. Heat pipes are tubular structures that use the principle of phase change to transfer heat. The choice of heat sink type depends on the application, cooling requirements, and other factors.

Maintenance of Heat Sink

Maintenance of heat sink is essential to ensure its longevity and optimal performance. The surface of the heat sink should be cleaned periodically to remove any dust, debris, or other contaminants that can obstruct airflow. The thermal paste or compound should be replaced periodically to maintain optimal contact between the electronic component and the heat sink. The mounting pressure should also be checked and adjusted if necessary, to ensure uniform contact pressure.

Compatibility with Electronic Components

The compatibility of the heat sink with the electronic component is crucial for optimal performance. The heat sink should be designed to fit the shape, size, and orientation of the component for maximum contact area. It is also essential to consider the thermal requirements and limitations of the components and choose a heat sink that can meet those requirements. Improper compatibility can lead to reduced performance or even damage to the components.

Cost of Heat Sink

The cost of a heat sink can vary depending upon several factors such as the material used, design, and type. Copper heat sinks are more expensive than aluminum heat sinks. A well-designed and efficient heat sink may also cost more. However, the cost of the heat sink should be evaluated against its performance and its suitability for the application.

Conclusion

Heat sinks are crucial components of any electronic device to prevent overheating and potential damage. It is essential to consider several factors such as material, design, installation, maintenance, and compatibility to ensure optimal performance. Choosing the right heat sink can improve the lifespan and efficiency of the electronic device while ensuring reliable performance.