The Basics of Extrusion Heat Sink

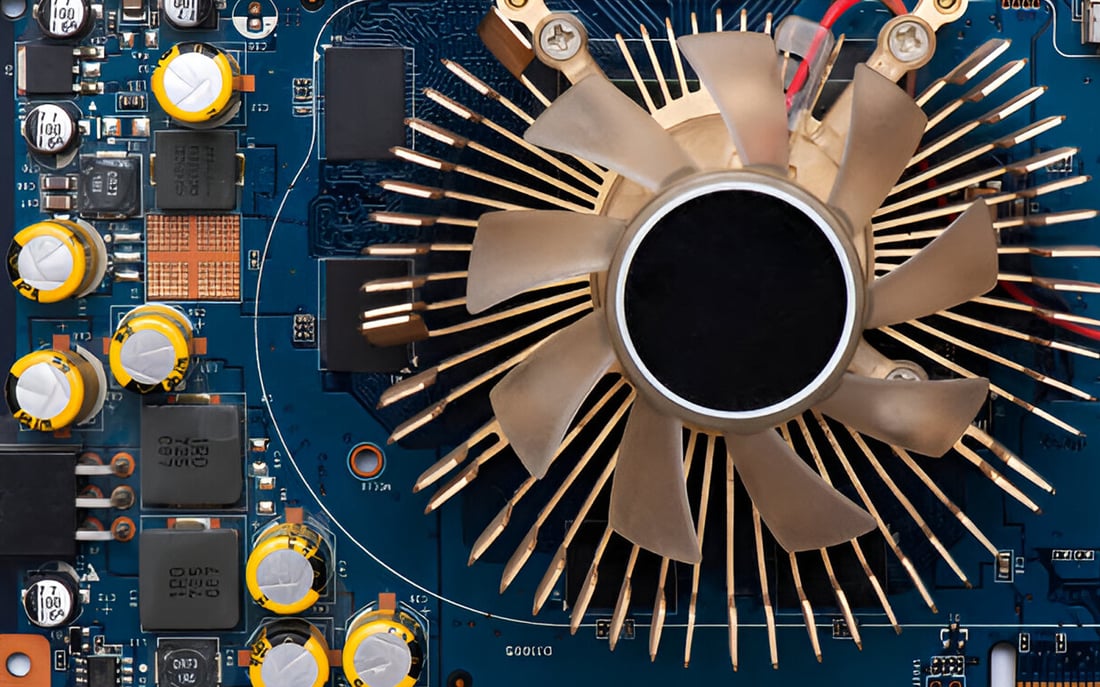

An extrusion heat sink is an essential device in the field of electronics that works to dissipate heat from electronic components. It is made from aluminum and features fins that conduct the heat outwards.

What are the Benefits of Extrusion Heat Sink?

One of the key benefits of extrusion heat sink is that it is a passive cooling solution, as it does not require external power or maintenance. This makes it efficient for heat dissipation and quiet operation. It is also very reliable, durable, and cost-effective.

How is Extrusion Heat Sink Made?

To make an extrusion heat sink, aluminum is first heated to a high temperature, then pushed through a die using hydraulic pressure, which shapes the metal into the desired profile. The resulting extrusion is then cut into lengths and finished with surface treatments such as anodization or powder coating.

What Types of Extrusion Heat Sink are There?

There are many different types of extrusion heat sink, each with varying shapes and sizes. These include standard, high-density, and low-profile designs, as well as custom shapes and sizes for specific applications.

What Factors Affect Extrusion Heat Sink Efficiency?

There are several factors that can affect the efficiency of an extrusion heat sink, including its size, design, surface finish, the thermal conductivity of the material, and the number and distribution of fins.

How is Extrusion Heat Sink Installed?

Extrusion heat sinks are typically installed directly onto the electronic component using thermal interface materials such as thermal pastes or pads. They are usually attached with screws or clips.

What are the Applications of Extrusion Heat Sink?

Extrusion heat sinks are used in a wide range of electronic applications, including LED lighting, power supplies, computer processors, audio amplifiers, and automotive electronic control units.

What are the Key Advantages of Using Extrusion Heat Sink?

The main advantages of using extrusion heat sink in your electronic devices are reduced operating temperatures, improved reliability and lifespan, decreased risk of failure, and consistent performance.

How to Choose the Right Extrusion Heat Sink?

When choosing an extrusion heat sink, it is important to consider factors such as thermal management requirements, environment, size and shape constraints, cost, and customization options. Consulting with a professional heat sink manufacturer can help determine the best solution for your needs.

The Future of Extrusion Heat Sink

As electronic devices continue to become smaller and more complex, the demand for efficient and effective thermal management solutions will only increase. Extrusion heat sink will continue to play a vital role in ensuring the longevity and performance of these devices.