What can be used as a heat sink? Exploring Different Options

Heat sinks are vital components in many electronic devices as they help dissipate heat and prevent overheating. They are commonly used in computer processors, LED lights, power amplifiers, and many other applications. While traditional heat sinks are typically made of metal, there are various alternative materials that can be used effectively. In this article, we will explore different options for what can be used as a heat sink, including unconventional materials and techniques.

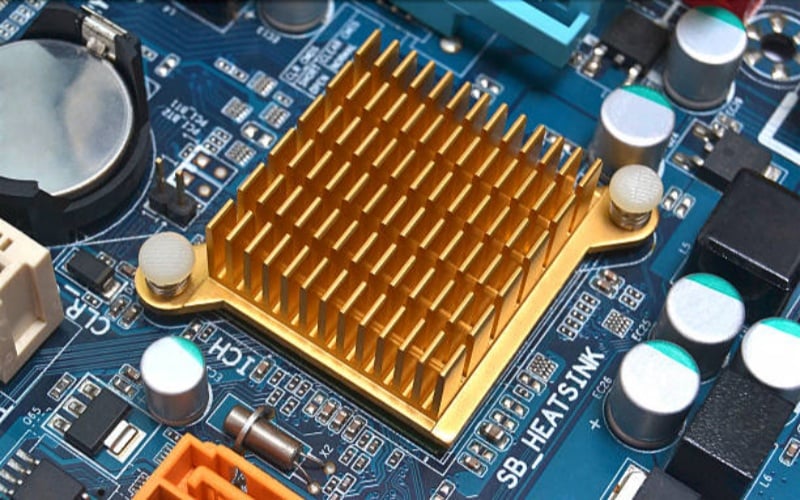

1. Metal Heat Sinks: The Traditional Choice

Metal heat sinks, such as aluminum or copper, have been widely used for their excellent thermal conductivity and heat dissipation properties. These materials are capable of efficiently transferring heat from the source to the surrounding environment. Aluminum heat sinks are lightweight, cost-effective, and commonly used in consumer electronics. Copper heat sinks, on the other hand, offer superior thermal conductivity but are heavier and more expensive.

2. Heat Pipes: Efficient Heat Transfer

Heat pipes are another popular option for heat dissipation. These sealed copper tubes contain a small amount of working fluid that evaporates and condenses to transfer heat rapidly. Heat pipes can be used to create highly efficient heat sinks, particularly in applications where space is limited. They are commonly found in high-performance computers, aerospace systems, and industrial equipment.

3. Vapor Chambers: Enhanced Heat Spreading

Vapor chambers are advanced heat spreaders that provide improved thermal conductivity compared to traditional heat sinks. These thin, flat devices consist of a sealed chamber filled with a small amount of working fluid. By utilizing the heat pipe principle, vapor chambers can quickly spread heat across their surfaces, allowing for more efficient cooling. They are commonly used in high-power electronics and LED lighting applications.

4. Graphite Heat Sinks: Lightweight and Versatile

Graphite heat sinks are gaining popularity due to their lightweight nature and excellent thermal conductivity. These heat sinks are made from layers of graphite sheets stacked together, allowing for efficient heat dissipation. Graphite heat sinks are commonly used in mobile devices, power electronics, and automotive applications. Their versatility and ability to be customized make them ideal for various thermal management needs.

5. Thermoelectric Coolers: Active Cooling Solutions

Thermoelectric coolers, also known as Peltier devices, provide active cooling by using the Peltier effect to transfer heat. These devices consist of semiconductors that create a temperature gradient when an electric current is applied. Thermoelectric coolers can be used as both heat sinks and active cooling solutions, making them suitable for applications where conventional cooling methods are insufficient.

6. Liquid Cooling: Efficient Heat Transfer

Liquid cooling systems offer superior heat dissipation compared to traditional air cooling methods. These systems use a liquid, such as water or coolant, to transfer heat away from the source. Liquid cooling can be achieved through various methods, including water blocks, heat exchangers, and pumps. It is commonly used in high-performance computers, gaming rigs, and overclocking applications.

7. Phase Change Materials: Effective Thermal Storage

Phase change materials (PCMs) are substances that can absorb and release large amounts of heat during phase transitions. These materials can be used as passive heat sinks by absorbing heat from the source until they reach their phase change temperature, at which point they release the stored heat. PCMs are commonly used in electronic enclosures, where they act as thermal buffers to prevent temperature spikes and maintain a stable operating environment.

8. Thermal Adhesives: Improving Heat Transfer

Thermal adhesives are substances used to enhance heat transfer between a heat-generating component and a heat sink. These adhesives fill in gaps and air pockets, ensuring maximum contact and improved thermal conductivity. They are commonly used in applications where secure attachment and efficient heat transfer are crucial, such as in power modules, LED modules, and automotive electronics.

9. Natural Convection: Simplistic Cooling

Natural convection is a simple and passive cooling method that relies on the movement of air to dissipate heat. By creating fins or using a larger surface area, heat sinks can harness the natural flow of air to aid in heat dissipation. Natural convection is commonly used in low-power applications, where a basic heat sink design is sufficient.

10. Composite Materials: Combining Benefits

Composite materials, such as aluminum silicon carbide (AlSiC) or aluminum nitride (AlN) composites, combine the advantages of different materials to create highly effective heat sinks. These materials are designed to have high thermal conductivity, low coefficient of thermal expansion, and light weight. Composite heat sinks offer improved performance and reliability in applications where conventional materials may fall short.

heat sink, alternative heat sink materials, metal heat sinks, heat pipes, vapor chambers, graphite heat sinks, thermoelectric coolers, liquid cooling, phase change materials, thermal adhesives, natural convection, composite materials What Can Be Used as a Heat Sink? Exploring Different Options Discover various materials and techniques that can be used as heat sinks for efficient heat dissipation. Explore alternative options beyond traditional metal heat sinks.