Introduction

Vacuum brazed cold plates are an essential component in many industries, including electronics, aerospace, and medical. These specialized cooling devices play a crucial role in dissipating heat efficiently, ensuring the optimal performance and reliability of various electronic components. In this article, we will explore the features and benefits of vacuum brazed cold plates in detail.

Superior Thermal Conductivity of Vacuum Brazed Cold Plates

One of the key features of vacuum brazed cold plates is their exceptional thermal conductivity. The use of highly conductive materials, such as copper or aluminum, allows for efficient heat transfer from the heat source to the cooling fluid. This ensures that the temperature of the electronic components remains within safe operating limits, preventing overheating and potential damage.

Enhanced Heat Dissipation

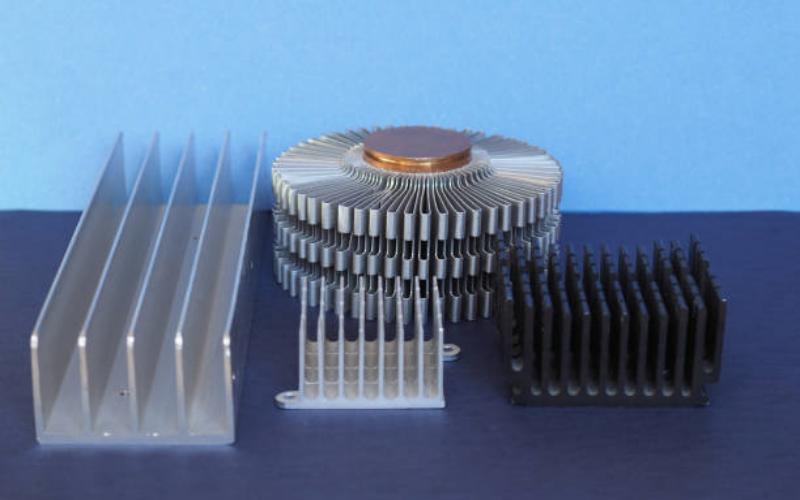

Vacuum brazed cold plates are designed to maximize heat dissipation. The intricate network of internal channels and fins within the cold plate allows for a larger surface area, promoting better heat transfer to the surrounding environment or cooling fluid. This design enables the cold plate to dissipate heat rapidly, leading to improved overall system performance and longevity.

Customizable Designs of Vacuum Brazed Cold Plates

Manufacturers of vacuum brazed cold plates offer a wide range of customization options to meet specific application requirements. From the dimensions and shape of the cold plate to the placement and number of fluid channels, customers can tailor the design to fit their cooling needs precisely. This versatility makes vacuum brazed cold plates suitable for a variety of applications, from high-power electronics to advanced medical devices.

Compact and Lightweight

Vacuum brazed cold plates are known for their compact and lightweight construction. The brazing process allows for the creation of thin, yet robust, cooling structures, minimizing the overall weight and footprint of the cold plate. This compactness is especially beneficial in space-constrained applications where size and weight are critical factors.

Excellent Corrosion Resistance of Vacuum Brazed Cold Plates

Another notable feature of vacuum brazed cold plates is their excellent corrosion resistance. The brazing process creates a metallurgical bond between the base material and the cooling channels, eliminating the need for additional coatings or protective measures. This inherent corrosion resistance ensures the longevity and reliability of the cold plate, even in harsh operating environments.

High Pressure and Leak Resistance

Vacuum brazed cold plates are designed to withstand high-pressure environments without compromising performance. The brazing process creates a seamless and leak-free joint between the cooling channels and the base material, ensuring the integrity of the cold plate even under extreme conditions. This feature is particularly crucial in applications where coolant leakage can lead to system failure or safety hazards.

Optimized Fluid Flow

The design of vacuum brazed cold plates allows for optimized fluid flow, maximizing the cooling efficiency. The internal channels are strategically designed to ensure uniform distribution of the cooling fluid, minimizing any hotspots and maintaining consistent temperatures across the cooling surface. This efficient fluid flow enhances the overall cooling performance of the cold plate.

Easy Integration

Vacuum brazed cold plates are designed for easy integration into existing systems. They often feature standard mounting hole patterns and fluid connections, making it straightforward to replace or upgrade existing cooling solutions. This easy integration minimizes downtime and allows for seamless integration of vacuum brazed cold plates into various applications.

Long-Term Reliability of Vacuum Brazed Cold Plates

Due to their robust construction and excellent thermal management capabilities, vacuum brazed cold plates offer long-term reliability. The absence of joints or seams in the cooling channels ensures consistent performance over time, minimizing the risk of failures or degradation. This reliability is crucial, especially in critical applications where system downtime can have severe consequences.