The Basics of Water Cooling Plates

Water cooling plates are essential components in many cooling systems, especially in high-performance applications such as electronics or automotive engines. These plates are designed to efficiently remove heat from a surface by circulating water through channels within the plate. By Understanding the Science Behind Water Cooling Plates, engineers can optimize their performance and ensure effective heat dissipation.

Heat Transfer Mechanism

Water cooling plates utilize the principles of conduction and convection to transfer heat away from a hot surface. When water flows through the channels in the plate, it absorbs heat from the surface through conduction. The heated water is then carried away from the plate and replaced with cooler water, promoting heat dissipation through convection. This continuous cycle helps to maintain the temperature of the surface within a desired range.

Materials and Design Considerations

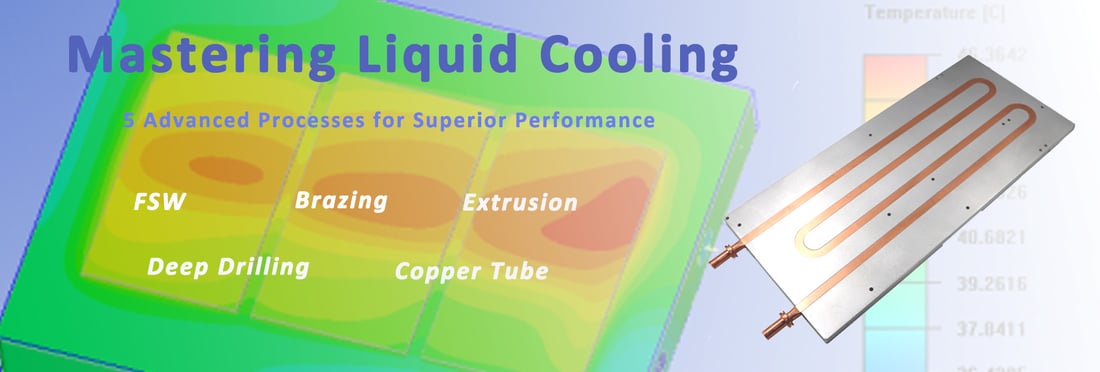

The effectiveness of water cooling plates depends on the materials used and the design of the plate. Typically, these plates are made from materials with high thermal conductivity, such as aluminum or copper, to facilitate efficient heat transfer. The design of the plate, including channel geometry and flow distribution, also plays a crucial role in optimizing heat dissipation.

Thermal Resistance and Efficiency

Thermal resistance is a key parameter used to evaluate the effectiveness of water cooling plates. Lower thermal resistance indicates better heat transfer efficiency, as it signifies a smaller temperature difference between the hot surface and the cooling water. Engineers can achieve lower thermal resistance by maximizing contact between the surface and the water channels, as well as improving the flow rate of the water.

Applications of Water Cooling Plates

Water cooling plates find applications in various industries, including electronics cooling, power electronics, laser systems, and automotive cooling. These plates are especially useful in high-power devices or systems that generate a significant amount of heat. By incorporating water cooling plates, engineers can ensure reliable operation and prevent overheating issues.

Advantages of Water Cooling Plates

One of the main advantages of water cooling plates is their ability to achieve high heat transfer rates compared to traditional air cooling methods. Water has a much higher thermal conductivity than air, allowing for more efficient heat removal. Additionally, water cooling plates can be customized to fit specific cooling requirements, making them versatile and adaptable to different applications.

Integration with Cooling Systems

Water cooling plates can be integrated into larger cooling systems to enhance overall thermal management. By combining water cooling plates with other cooling technologies such as heat sinks or fans, engineers can create comprehensive cooling solutions that effectively dissipate heat from critical components. This integration ensures optimal performance and reliability in demanding environments.

Thermal Management in Electronics

In electronics applications, effective thermal management is vital to ensure the long-term reliability and performance of electronic devices. Water cooling plates offer a viable solution for managing heat in high-power electronic systems, enabling efficient cooling and temperature control. By implementing water cooling plates, engineers can improve the overall efficiency and lifespan of electronic components.

Challenges and Limitations

Despite their benefits, water cooling plates also present challenges and limitations. Proper maintenance and monitoring are essential to prevent issues such as corrosion, leaks, or flow restrictions in the water channels. Moreover, the complexity of integrating water cooling plates into existing systems may require additional design considerations and testing to ensure compatibility and optimal performance.

Future Trends and Innovations

As technology advances and demands for high-performance cooling solutions continue to grow, the future of water cooling plates looks promising. Innovations in materials, manufacturing techniques, and thermal management strategies are driving improvements in water cooling plate design and efficiency. By staying informed about these developments, engineers can leverage the latest innovations to enhance their cooling systems and meet evolving industry requirements.