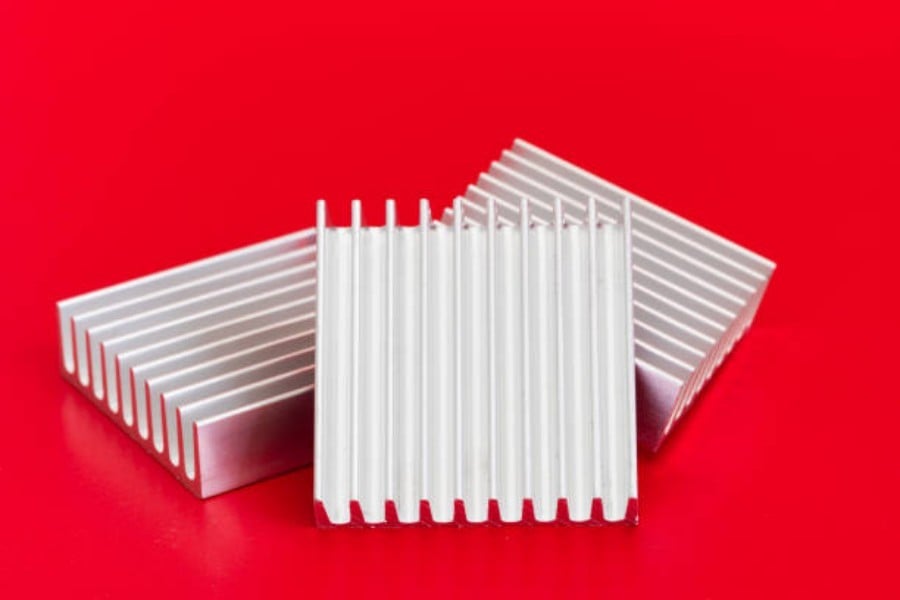

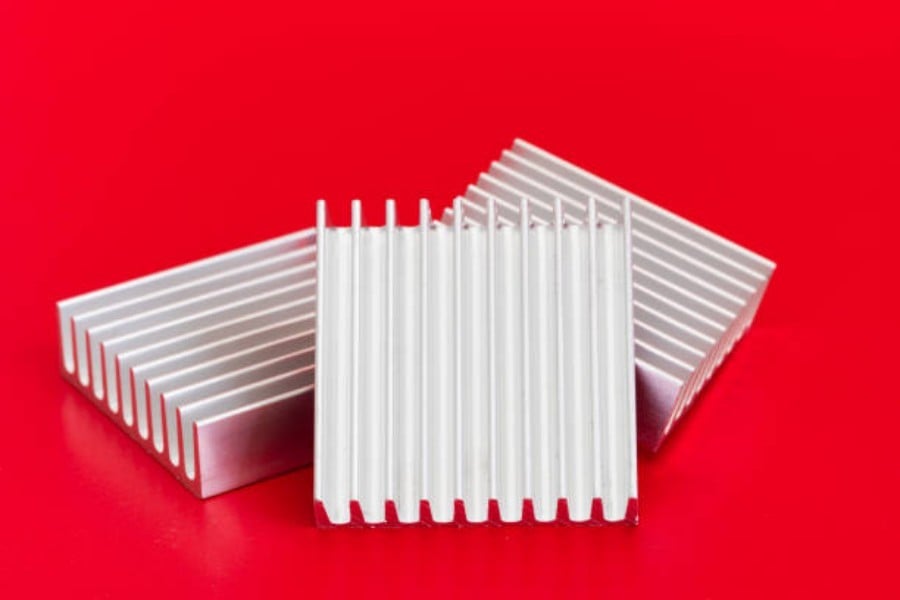

When electronic devices operate, they generate heat. Power supply heat sinks are used to manage the heat produced by power electronics. The power supply heat sink's primary function is to dissipate heat, keeping electronic devices at an optimal temperature for efficient performance. It is a passive device that does not consume energy.

How Does A Power Supply Heat Sink Work?

A power supply heat sink works by providing a means by which heat can be conducted away from the power supply unit. The design of the heat sink allows for an increased surface area in contact with air or other cooling mediums. This increased surface area facilitates greater heat dissipation, which is essential for proper electronics operation. The heat sink works as a thermal conductor, connecting the electronic devices directly to the external environment for cooling.

The Importance of Power Supply Heat Sinks

Heat is the primary culprit for the failure or reduced lifespan of electronic devices. The absence of a power supply heat sink could result in overheating and eventual device failure. The increased temperature leads to the degradation of the device’s performance, making it difficult to operate efficiently. Power supply heat sinks provide the necessary thermal management that ensures correct electronic devices function and improves their lifespan.

Types of Power Supply Heat Sinks

There are several types of power supply heat sinks with varying designs and functions. The most common are passive heat sinks, active heat sinks, and liquid cooling heat sinks. Passive heat sinks dissipate heat through natural convection, while active heat sinks use a fan or pumps for forced convection. Liquid cooling heat sinks use a liquid coolant to dissipate heat, and they perform optimally when working alongside more substantial electronic devices.

Factors Determining The Performance Of Power Supply Heat Sinks

Several factors affect the performance of a power supply heat sink. The surface area to volume ratio, the thermal conductivity of the heat sink, and the coolant or the air flow. To increase performance, it is essential to use a heat sink designed with the right size, material, and shape to accommodate maximum performance.

How To Choose The Right Power Supply Heat Sink

Choosing the right power supply heat sink is critical to enhance the life and performance of your electronic device. As such, several design aspects, including the materials used, manufacturing techniques, and shape, must be considered.

Materials

The most commonly used materials for power supply heat sinks are aluminum and copper. Copper offers higher thermal conductivity but is relatively expensive. Aluminum, on the other hand, is cheaper and lightweight, making it a popular choice.

Manufacturing Techniques

There are two common methods used in power supply heat sink manufacturing. The first method is aluminum extrusion, which is most suitable for small to medium-sized heat sinks. The second method is forging, which is better for larger heat sinks.

Shape and Design

The shape and design of the power supply heat sink is also an important consideration. Different shapes and designs offer varying performance benefits, and, as such, it is crucial to select the right design that suits your electronic device.

Maintenance of Power Supply Heat Sinks

Maintenance of a power supply heat sink is essential to ensure optimal performance. Keeping the heat sink clean and free from debris or dust ensures proper airflow within the power supply unit. Regular inspections and cleaning of the heat sink are necessary for the prevention of overheating and device failure.

power supply heat sink, electronics, thermal management, performance, materials, manufacturing, design, maintenance

The Importance of Power Supply Heat Sink for Your Electronics

Learn about the importance of power supply heat sinks for your electronics. Enhance their life and performance with a quality heat sink. Read more here.

Quote Inquiry