The Basics of a cold plate cooling system

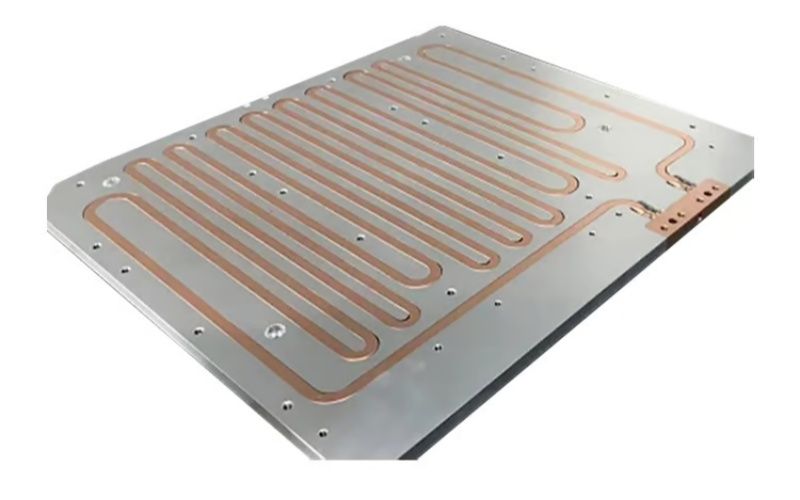

A cold plate cooling system is a thermal management solution that is used to cool down electronic components that tend to generate excessive heat. It is a popular choice for high-performance electronic applications, such as data centers, medical equipment, military and aerospace systems, and electric vehicles. The basic concept behind a cold plate cooling system is the transfer of heat from the electronic components to a fluid that is circulated through channels within a thermally conductive plate.

Cooling Efficiency

A cold plate cooling system is a highly efficient method for cooling electronic components and dissipating heat. The thermal conductivity of a cold plate is typically ten times greater than that of air-cooling devices. As a result, it can handle high heat loads and maintain a stable temperature. Cold plates can also be customized to meet specific cooling requirements, such as different dimensions, flow rates, and inlet/outlet configurations, depending on the application.

Noisless and Low Vibration

Cold plates are an ideal choice for noise-sensitive applications as they do not rely on fans or blowers to cool the electronic components. The lack of moving parts in cold plate cooling systems means that they are much quieter than traditional cooling methods. In addition to being silent, cold plates also have a low vibration, which can prevent wear and tear on sensitive components over time, ultimately increasing the lifespan of the electronics.

Minimal Maintenance

Another advantage of using a cold plate cooling system is that they require minimal maintenance compared to conventional cooling methods. Since cold plate heat exchangers do not contain any moving parts, they have a lower risk of failure. Cleaning is also easy as the hardware is simple to disassemble and clean without the need for any special cleaning agents.

Cost-Effective

Cold plate cooling systems are cost-effective as they use simple hardware, require less maintenance and consume less electricity. While initial installation costs can be higher than traditional cooling systems, cold plates typically have a longer lifespan, which can lead to significant cost savings over time. In addition, a cold plate's efficiency and reliability can reduce the failure rate of electronic components, further lowering long-term costs due to maintenance, repairs, and replacements.

Flexible Design Options

Cold Plate cooling systems offer a high degree of flexibility in their design, making it easier to meet specific application and cooling requirements. Custom size and shapes are attainable and the fittings and hoses can be made to match the specific inlets and outlets required. Because of the ease of installation, they are also a good choice for retrofitting and upgrading existing systems that require better cooling performance.

Environmentally Friendly

Cold Plate cooling systems are more environmentally friendly than other cooling options. For example, liquid cooling is an efficient way to dissipate heat from electronic devices and reduces the need for more air-conditioning. This could lead to a significant reduction in carbon footprints for data centers and server farms.

Better Performance

Since cold plate cooling systems effectively transfer heat out of the electronic components, it can help improve performance compared to other cooling methods. This is best achieved when the heat produced is effectively transferred to the cold plate where it can be dissipated away thereby minimizing any instance of overheating.

High-Stress Applications

Cold plate cooling systems are effective in high-stress applications, like military and aerospace, medical devices, and electric vehicles since they can address the thermal concerns within the devices. Their high cooling capacity makes them the best choice to work in extreme temperature environments and ensures higher efficiency, and thereby improving the lifespan of the electronics.

Effective Cooling for High Watt Densities

With the constant evolution of electronic technology, the heat load of devices has increased significantly. A cold plate cooling system can offer efficient cooling of high watt densities. Cold plate cooling systems handle heat flux densities that other cooling technologies find challenging and require complex systems that add to the cost of the product.

Easy Integration

Cold plate cooling systems can be easily integrated into electronic assemblies. Modular cold plates can be integrated into systems with the goal of modularity and scalability. Standard, well-designed cold plates are avaliable and can be adapted to meet specific requirements for many different types of applications and systems.