Introduction

extrusion heat sink has been widely used as a heat dissipation solution in various electronic devices. It is designed to efficiently dissipate heat produced by electronic components to ensure their proper functioning. This article aims to explain what extrusion heat sink is, how it works, and its advantages over other heat dissipation methods.

What is Extrusion Heat Sink?

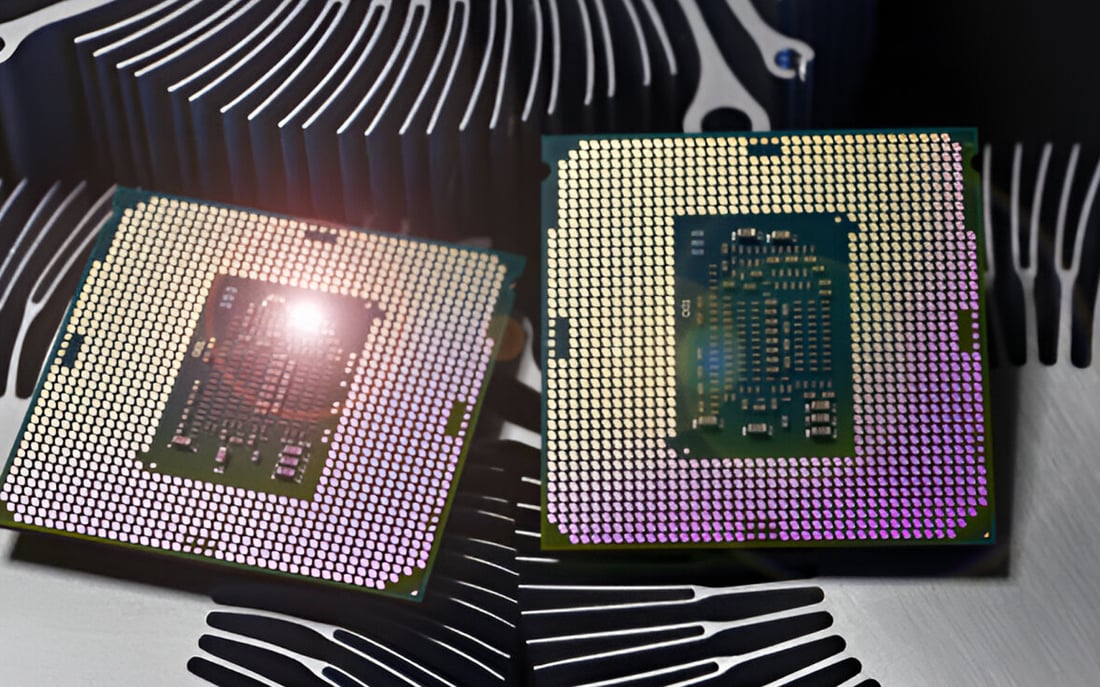

Extrusion heat sink is a type of heat sink that is created by shaping aluminum or copper into a desired form through extrusion. The extruded material is then cut to a specific length for use in electronic devices. Extrusion heat sink can be designed in various shapes and sizes to fit different requirements and has excellent heat dissipation abilities.

How Does it Work?

Extrusion heat sink works by conducting heat from the heat source, such as a microprocessor or LED, and dissipate it into the ambient air through its extended surface area. The heat sink fins increase the surface area and create turbulence, which helps to generate natural convection currents to enhance heat dissipation. Extrusion heat sinks can also be paired with a fan to improve heat transfer and cooling efficiency.

Advantages of Extrusion Heat Sink

High Thermal Efficiency

Extrusion heat sink has a high thermal efficiency, which means it can effectively and quickly dissipate a large amount of heat. The extrusion process creates intricate fin designs, making it suitable for use in high-power electronic devices that generate significant amounts of heat.

Customizable Design

Extrusion heat sink can be easily customized into various shapes and sizes to meet the specific requirements of electronic devices. It can also be designed in various colors and finishes to match the aesthetic of the device.

Cost-Effective Solution

The extrusion process of heat sink production is a cost-effective solution for heat dissipation. The process is highly automated, meaning that the cost of manufacturing is low compared to other heat sinks. Extrusion heat sink also has a longer lifespan and requires little to no maintenance, making it a cost-effective solution in the long run.

Lightweight and Durable

Extrusion heat sink is lightweight and has a high strength-to-weight ratio, making it an ideal solution for portable electronic devices. It is also highly durable, which ensures its longevity and reliability.

Eco-Friendly Solution

Extrusion heat sink is made from recyclable material, which makes it an eco-friendly solution. In addition, the extrusion process is energy-efficient, reduces waste, and has a lower carbon footprint than traditional heat sink manufacturing processes.

Easy to Install

Extrusion heat sink is easy to install, making it a popular choice for electronic device manufacturers. It can be attached to the device through various methods, such as clips, screws, or thermal interface materials.

Excellent Electrical Insulation

Extrusion heat sink has excellent electrical insulation properties which make it safe to use in electronic devices. It also provides electromagnetic interference (EMI) shielding and radio frequency (RF) attenuation to ensure the proper functioning of the device.

Wide Range of Applications

Extrusion heat sink is widely used in various electronic devices, including PCs, laptops, LED lights, smartphones, and tablets. Its versatile design can meet the specific requirements of different electronic devices and ensure their proper functioning.

Improved Performance and Reliability

Extrusion heat sink improves the performance and reliability of electronic devices by preventing them from overheating. Overheating can damage electronic components, reduce their lifespan, and affect their performance. Extrusion heat sink ensures that electronic devices operate within their optimal temperature range, enhancing their performance and reliability.

Noise Reduction

Extrusion heat sink can reduce noise in electronic devices by eliminating the need for a fan. The extruded fins increase the surface area of the heat sink and create natural convection currents, which cool the electronic components silently.

Conclusion

Extrusion heat sink is a highly efficient and cost-effective solution for heat dissipation in electronic devices. It has various advantages over other heat dissipation methods, including customizable design, lightweight, durability, and silent cooling. Its versatility and wide range of applications make it a popular choice for electronic device manufacturers who need to ensure the proper functioning and longevity of their products.