Improved Heat Dissipation

One of the major advantages of liquid cold plate heat sinks is their ability to efficiently dissipate heat. Traditional air-cooled heat sinks rely on the movement of air to transfer heat away from the electronic components. However, liquid cold plate heat sinks use a liquid coolant, such as water or a specialized fluid, to directly absorb and carry away heat. This direct contact allows for faster and more efficient heat transfer, resulting in lower operating temperatures for the electronic devices.

Uniform Cooling of Liquid Cold Plate Heat Sink

Another advantage of liquid cold plate heat sinks is their ability to provide uniform cooling across the entire surface. With air-cooled heat sinks, the cooling effectiveness may vary depending on the airflow distribution. On the other hand, liquid cold plate heat sinks distribute the cooling fluid evenly over the surface, ensuring consistent and uniform cooling for all the components. This helps prevent hotspots and ensures optimal performance of the electronic devices.

High Heat Dissipation Capacity

Liquid cold plate heat sinks have a higher heat dissipation capacity compared to air-cooled heat sinks. The liquid coolant used in these heat sinks has a higher thermal conductivity than air, allowing it to absorb and carry away more heat. This increased capacity is particularly beneficial for high-power electronic devices that generate a significant amount of heat. Liquid cold plate heat sinks can effectively handle the elevated heat loads and prevent overheating.

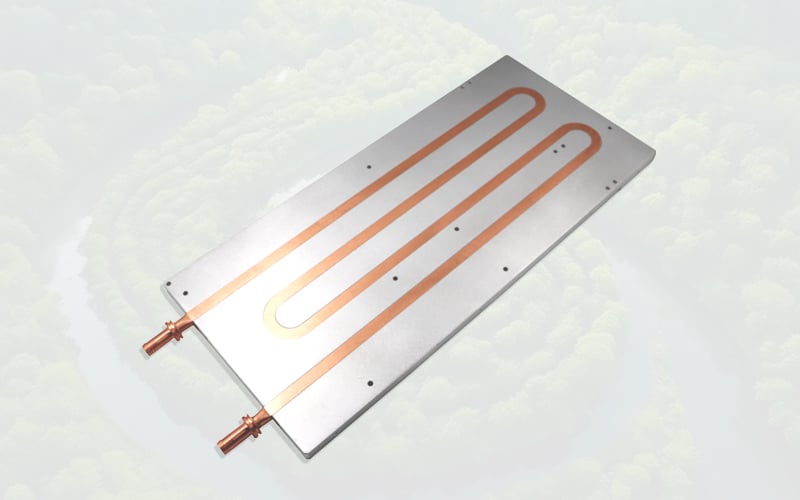

Compact Design of Liquid Cold Plate Heat Sink

Liquid cold plate heat sinks offer a more compact design compared to traditional air-cooled heat sinks. The use of liquid coolant eliminates the need for bulky heat sink fins and fans, resulting in a more streamlined and space-saving solution. This compact design is especially advantageous in applications where space is limited, such as in compact electronic devices or densely populated circuit boards.

No Fan Noise

Unlike air-cooled heat sinks that rely on fans for heat dissipation, liquid cold plate heat sinks operate silently. The absence of fans eliminates any potential noise pollution, making them ideal for noise-sensitive environments or applications that require quiet operation. This advantage is particularly important in applications such as audio equipment, medical devices, or home appliances where noise reduction is crucial.

Improved Reliability of Liquid Cold Plate Heat Sink

Liquid cold plate heat sinks contribute to improved reliability of electronic devices. By effectively dissipating heat and maintaining lower operating temperatures, they help prolong the lifespan of the components. High temperatures can accelerate component degradation and lead to premature failure. By keeping the temperatures in check, liquid cold plate heat sinks ensure the long-term reliability and performance of the electronic devices.

Customizable Solutions

One of the key advantages of liquid cold plate heat sinks is their versatility and customization options. These heat sinks can be designed and manufactured to meet specific application requirements. The shape, size, and layout of the cold plates can be tailored to fit the unique needs of the electronic device or system. This flexibility allows for efficient heat dissipation in complex or unconventional designs, ensuring optimal thermal management.

Compatibility with Various Coolants

Liquid cold plate heat sinks offer compatibility with a wide range of coolants. While water is a commonly used coolant, specialized fluids with enhanced thermal properties can also be utilized. These coolants can be selected based on the specific cooling requirements and environmental conditions of the application. The ability to choose from different coolants provides flexibility and ensures efficient heat transfer in various operating conditions.

Easy Maintenance

Maintaining liquid cold plate heat sinks is relatively easy compared to air-cooled heat sinks. Traditional heat sinks with fans require regular cleaning and maintenance to remove dust and debris that can accumulate on the fins and obstruct airflow. In contrast, liquid cold plate heat sinks do not have fins or fans, simplifying the cleaning process. Additionally, any coolant leaks or issues can be easily identified and addressed, ensuring the continued performance of the heat sink.

Sustainable and Environmentally Friendly

Liquid cold plate heat sinks offer a sustainable and environmentally friendly cooling solution. Unlike air-cooled heat sinks that rely on energy-consuming fans, liquid cold plate heat sinks do not contribute to energy consumption or greenhouse gas emissions. Furthermore, the coolants used in these heat sinks can be selected from environmentally friendly options, minimizing the environmental impact. This makes liquid cold plate heat sinks a greener choice for thermal management in electronic devices.