What is Stamping Heat Sink?

Stamping heat sink is a process used in the manufacturing of heat sinks. A heat sink is a device that is used to dissipate heat from electronics or other devices. Stamping involves the use of a machine that presses a metal sheet into a specific shape or design. In the case of heat sinks, the metal sheet is pressed into a unique design that promotes efficient heat transfer.

Types of Stamping Heat Sink

There are several types of stamping heat sink used in the electronics industry. The most common types are aluminum heat sinks and copper heat sinks. Aluminum heat sinks are most popular because they are lightweight and easy to manufacture. Copper heat sinks, on the other hand, are more expensive to produce but are more efficient in heat transfer.

Stamping Process for Heat Sinks

The stamping process for heat sinks involves several steps. First, a computer-aided design (CAD) drawing of the desired shape is created. The metal sheet is then placed in the stamping machine, and the machine presses the metal sheet into the desired shape. The heat sink is then subjected to various finishing processes that may include painting, anodizing, or powder coating.

Benefits of Stamping Heat Sink

Stamping heat sink has several benefits over other manufacturing processes. Firstly, it is a low-cost manufacturing process that results in high-volume production of heat sinks. Secondly, the process allows for the creation of complex shapes and designs that enhance the heat transfer efficiency of the heat sink. Thirdly, stamped heat sinks have a smooth surface finish that provides an aesthetically appealing look.

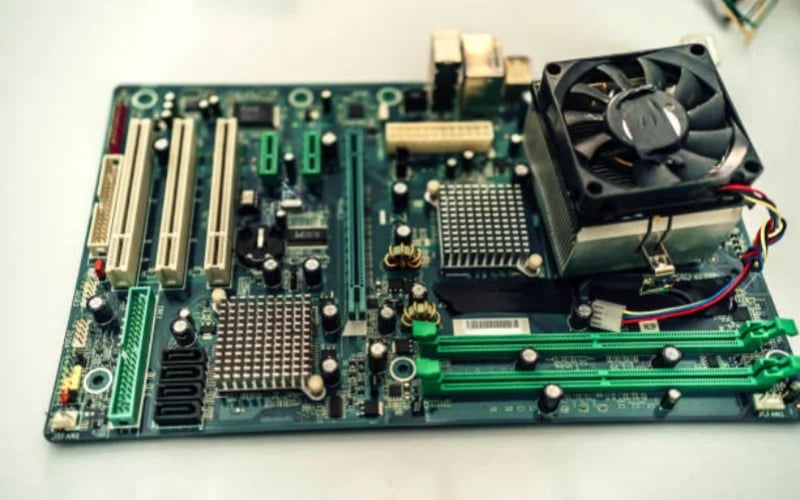

Applications of Stamped Heat Sinks

Stamped heat sinks have a wide range of applications in the electronics industry. They are used in computers, laptops, LED lights, power supplies, and other devices that generate a lot of heat. The use of stamped heat sinks helps to prevent overheating of electronic devices, which can damage or reduce their lifespan.

Factors to Consider When Designing a Stamped Heat Sink

When designing a stamped heat sink, several factors need to be considered. The size and shape of the heat sink should be optimized for the specific application. The material used in the manufacturing of the heat sink should be selected based on its thermal conductivity and cost. The design should also take into account the airflow patterns and the orientation of the heat sink with respect to the device.

Stamping vs. Extrusion Heat Sink

Another popular manufacturing process for heat sinks is extrusion. Extrusion involves the use of a die to create a specific shape or design. The main difference between extrusion and stamping is that extrusion results in a continuous profile. On the other hand, stamping allows for the creation of unique and complex shapes.

Stamping Heat Sink Manufacturers

There are several manufacturers of stamped heat sinks in the market. Some of the popular ones include Aavid Thermalloy, Advanced Thermal Solutions, Wakefield-Vette, and Radian Thermal Products. These companies provide high-quality stamped heat sinks that are designed for specific applications.

Care and Maintenance of Stamped Heat Sinks

Stamped heat sinks require little maintenance as they are made of durable materials that are resistant to wear and tear. However, it is essential to keep the heat sinks clean to prevent the accumulation of dust and other particles that may affect their heat transfer efficiency. Regular cleaning with a damp cloth is sufficient to keep the heat sink in good condition.

Conclusion

Stamped heat sinks are an essential component of electronic devices that generate a lot of heat. The use of stamped heat sinks helps to prevent the overheating of devices, which can reduce their lifespan. The process of stamping heat sinks is a low-cost and efficient manufacturing process that allows for the production of complex and efficient designs. With the right design, material selection, and maintenance, stamped heat sinks can provide reliable heat transfer for electronic devices for years to come.