The Rise of Stamped Heat Sinks: Revolutionizing Thermal Management

Stamped heat sinks have gained widespread use in various industries due to their exceptional thermal management capabilities. These versatile components efficiently dissipate heat from electronic devices, ensuring optimal performance and longevity. This article explores the various aspects of stamped heat sinks, including their construction, benefits, applications, and the future of this innovative technology.

Understanding Stamped Heat Sinks

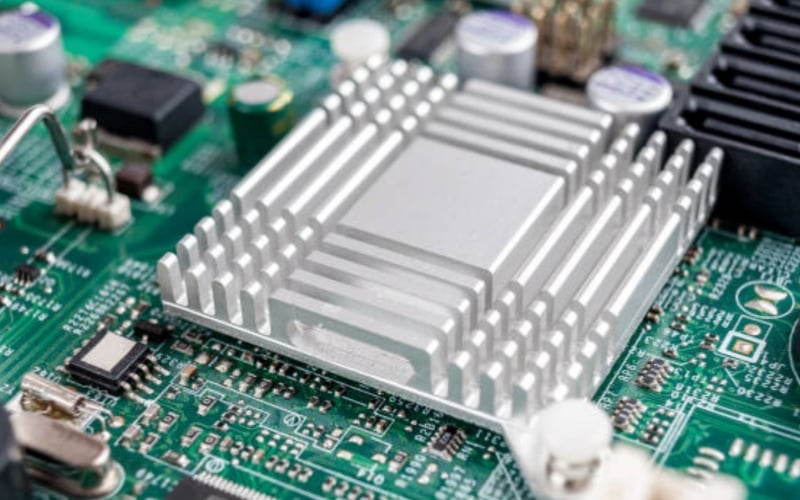

Stamped heat sinks are precisely manufactured using a stamping process, which involves pressing or punching a metal sheet into a desired shape. Typically made from aluminum or copper alloys, these heat sinks feature a complex pattern of fins, pins, or other geometric structures that maximize surface area for efficient heat dissipation.

Compared to traditional extruded heat sinks, stamped heat sinks offer several advantages, such as improved thermal performance, reduced weight, and lower costs. The stamping process allows for intricate and customizable designs that can be tailored to specific thermal requirements, making them suitable for a wide range of applications.

The Benefits of Stamped Heat Sinks

Stamped heat sinks offer numerous benefits that make them the preferred choice for thermal management in various industries. Here are some key advantages:

Efficient Heat Dissipation

The intricate geometric patterns of stamped heat sinks provide a large surface area, enabling efficient heat dissipation. This ensures that electronic components stay within their optimal temperature range, preventing overheating and potential performance issues.

Lightweight Design

Stamped heat sinks are significantly lighter compared to traditional heat sinks, thanks to the use of thinner metal sheets. This lightweight design is particularly advantageous in industries where weight restrictions are a concern, such as aerospace and automotive applications.

Cost-Effective Solution

The stamping process allows for mass production of heat sinks, resulting in reduced manufacturing costs. Additionally, the use of less material and simplified designs contribute to overall cost savings. This cost-effectiveness makes stamped heat sinks an attractive option for businesses looking to optimize thermal management without breaking the bank.

Customizability and Design Flexibility

Stamped heat sinks offer unparalleled design flexibility, as the stamping process allows for intricate and customizable shapes. Manufacturers can tailor the heat sink's geometry to specific thermal requirements, ensuring optimal heat dissipation for different electronic components. This adaptability makes stamped heat sinks suitable for a wide range of devices and industries.

Applications of Stamped Heat Sinks

The versatility of stamped heat sinks enables their use in various industries where efficient thermal management is critical. Some prominent applications include:

Electronics and Telecommunications

Stamped heat sinks are extensively used in electronic devices such as computers, servers, routers, and power supplies. They efficiently dissipate heat generated by semiconductors, ensuring reliable performance and extending the lifespan of these components. In the telecommunications industry, stamped heat sinks are vital for cooling high-power radio frequency amplifiers and transmitters.

Automotive and Transportation

The automotive industry relies on stamped heat sinks for effective thermal management in electric vehicles, hybrid vehicles, and traditional combustion engines. These heat sinks can cool power electronics, batteries, LED lighting systems, and various engine components. The lightweight design of stamped heat sinks also contributes to fuel efficiency and overall vehicle performance.

Aerospace and Defense

Aerospace and defense applications often operate in extreme environments, making efficient thermal management crucial. Stamped heat sinks are used in avionics, radar systems, satellite communication systems, and military-grade electronics. Their lightweight and customizable design make them well-suited for these demanding applications.

Renewable Energy

Stamped heat sinks play a vital role in renewable energy systems, such as solar inverters, wind turbines, and power converters. These heat sinks help maintain the optimal operating temperature of power electronics, ensuring maximum energy conversion efficiency and system performance.

The Future of Stamped Heat Sinks

As technology continues to advance, the demand for efficient thermal management solutions will only increase. Stamped heat sinks are poised to play a significant role in the future of electronics and other industries. The ongoing development of new materials, advanced stamping techniques, and innovative designs will further enhance their performance, cost-effectiveness, and applicability.

The integration of heat pipes, vapor chambers, and other cooling technologies with stamped heat sinks will also open up new possibilities for even more efficient heat dissipation. Additionally, the adoption of additive manufacturing techniques, such as 3D printing, may revolutionize the production of stamped heat sinks, allowing for greater design complexity and reduced lead times.

In conclusion, stamped heat sinks have become widely used due to their exceptional thermal management capabilities, cost-effectiveness, and design flexibility. From electronics and telecommunications to automotive and renewable energy, these heat sinks have found applications in a wide range of industries. As technology continues to evolve, stamped heat sinks will undoubtedly play a crucial role in ensuring optimal performance and reliability of electronic devices in the years to come.