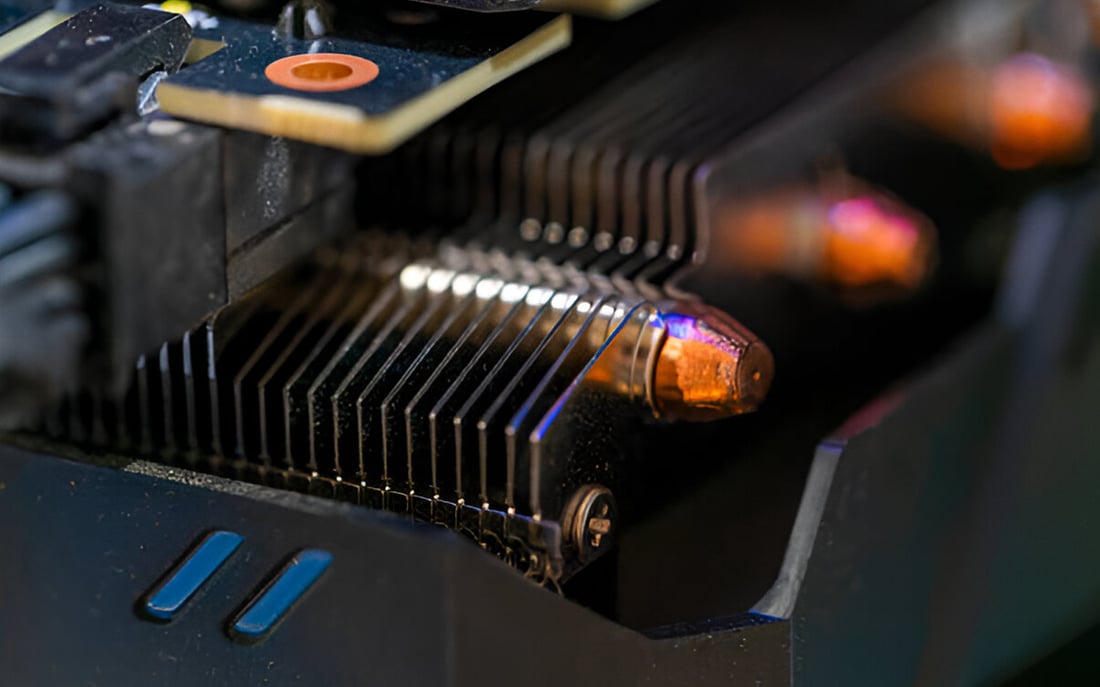

What are extruded aluminum heatsinks?

Extruded aluminum heatsinks are metal devices that are used to dissipate heat from electronic components. They are made by extruding aluminum into a desired shape and then cutting it to the required length. The fins help to increase the surface area of the heatsink, which enhances the dissipation of heat.

The Benefits of Extruded Aluminum Heatsinks

Extruded aluminum heatsinks are popular because they are lightweight, easy to manufacture, and cost-effective. They are also highly customizable, which means that they can be designed to fit various electronic components. Additionally, their high thermal conductivity ensures that the heat generated by the electronic components is dissipated efficiently.

Factors that Influence the Performance of Extruded Aluminum Heatsinks

The performance of an extruded aluminum heatsink is affected by various factors, such as the fin density, size, shape, and material properties. The fin density determines the surface area of the heatsink, while the size and shape affect how the heatsink interfaces with other components in the system. Additionally, the material properties of the heatsink such as thermal conductivity, specific heat, and density play a vital role in determining its overall performance.

How to Select the Right Extruded Aluminum Heatsink

When selecting an extruded aluminum heatsink, it is essential to consider the specific requirements of the application. The various factors to consider include the power dissipation levels of the electronic components, the available space in the system, the required airflow, and the temperature limits of the components. A heatsink with a higher thermal conductivity may be suitable for high-power applications, while a larger heatsink may be needed for systems with limited space.

The Importance of Proper Mounting of Extruded Aluminum Heatsinks

Mounting an extruded aluminum heatsink properly is crucial to its effectiveness. The heatsink should be mounted securely to the component to ensure optimal heat transfer. The use of a thermal interface material such as thermal grease or phase-change material can also improve thermal performance by filling in any gaps between the heatsink and the component.

The Impact of Surface Finish on Extruded Aluminum Heatsinks

The surface finish of an extruded aluminum heatsink can also affect its performance. A rough surface finish may create more turbulence, which can increase the heat transfer coefficient. On the other hand, a smooth surface finish may reduce the frictional resistance between the heatsink and the surrounding air, which leads to lower thermal resistance.

The Role of Extruded Aluminum Heatsinks in LED Lighting

LED lighting generates less heat than other lighting technologies such as incandescent bulbs. However, LEDs can still benefit from extruded aluminum heatsinks because they help dissipate the heat produced by the diodes. The use of extruded aluminum heatsinks can help to improve the efficiency and lifespan of LED lighting systems.

The Future of Extruded Aluminum Heatsinks

The use of extruded aluminum heatsinks will continue to grow as more and more electronic devices are developed. The demand for smaller, more efficient electronic components will drive the need for advanced heatsink technology. We can expect to see the development of new shapes, materials, and manufacturing processes that will enhance the performance of extruded aluminum heatsinks further.

Common Applications of Extruded Aluminum Heatsinks

Extruded aluminum heatsinks are used in a wide range of applications, including power supplies, audio amplifiers, motor drives, LED lighting, and computer systems. They are also used in automotive, aerospace, and medical industries, where efficient heat dissipation is critical.

Environmental Considerations of Extruded Aluminum Heatsinks

Extruded aluminum heatsinks are environmentally friendly due to their recyclability. Aluminum is the third-most abundant element in the Earth's crust, and its recycling rate is high. Recycling aluminum requires only 5% of the energy required to produce new aluminum from raw materials, making it a sustainable option.

Conclusion

Extruded aluminum heatsinks are essential components in electronic devices that generate heat. They are cost-effective, highly customizable, and easily manufactured, making them popular in a wide range of industries. Their performance is affected by various factors, including fin density, size, shape, and material properties. When selecting a heatsink, it's crucial to consider the specific requirements of the application. With the continued demand for smaller, more efficient electronic components, we can expect to see more advanced heatsink technology in the future.