Introduction

As technology advances, electronics are becoming more powerful and compact. However, with increased power comes increased heat, and this heat needs to be dissipated efficiently to avoid damage. This is where liquid cold plates come in, and in this article, we will explore the world of liquid cold plate manufacturers and everything you need to know about them.

What are Liquid Cold Plates?

Liquid cold plates are cooling solutions that use a combination of a metal plate and liquid coolant to dissipate heat from high-powered electronics. The liquid coolant flows through an array of channels within the plate, absorbing heat from the electronics, and then carries this heat away to a heat exchanger, where it is dispersed into the surrounding environment.

The Importance of Choosing the Right Liquid Cold Plate Manufacturer

The choice of liquid cold plate manufacturer is crucial to ensure the optimal performance of your cooling solution. With the wide variety of options available, it can be difficult to make the right choice. Some of the key factors to consider when selecting a manufacturer include product quality, manufacturing capabilities, customization options, and technical support.

Product Quality

The quality of the liquid cold plate is critical to ensure efficient heat dissipation. High-quality plates use materials with high thermal conductivity, such as copper or aluminum, to maximize heat transfer. They also have finely-tuned channel designs to ensure optimal flow rates and pressure drops. When selecting a manufacturer, it is important to ensure they produce plates that meet the stringent quality standards of the industry.

Manufacturing Capabilities

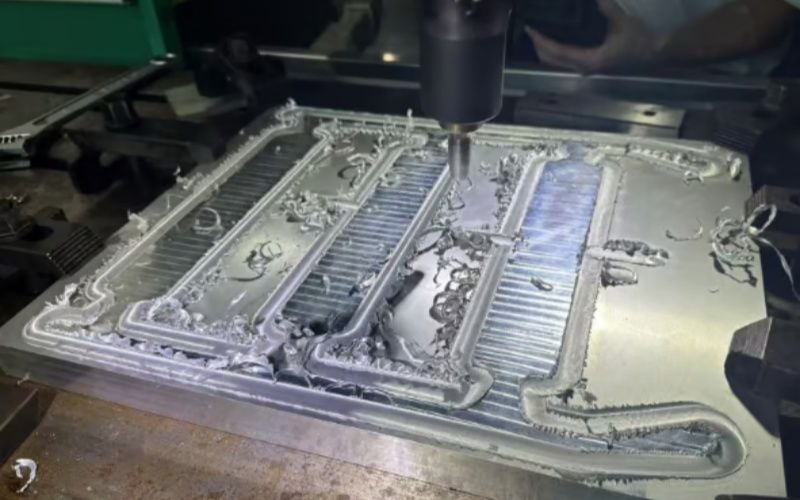

Manufacturing capabilities play a significant role in the quality of liquid cold plates. Advanced manufacturing technologies such as CNC machining, laser cutting, and additive manufacturing should be utilized to ensure precision and accuracy in the manufacturing process. These technologies also enable customization of the plates to meet unique requirements from customers in a cost-effective manner.

Customization Options

Every application has unique requirements, and it is important to select a manufacturer that can provide customization options to meet these needs. This includes options such as custom channel designs, materials, and coatings. With custom solutions, the liquid cold plate can be tailored to the specific cooling requirements of the application, leading to improved thermal performance and system efficiency.

Technical Support

Technical support is crucial to ensure the successful integration of liquid cold plates into the system. Manufacturers should provide dedicated support to assist with system design, installation, and troubleshooting. This support ensures that the plates are integrated efficiently and correctly into the larger system, leading to optimal performance and longevity.

Advantages of Liquid Cold Plates

There are several advantages that liquid cold plates offer over traditional air-based cooling solutions. Firstly, they offer superior thermal performance, as the liquid coolant provides a more effective heat transfer medium than air. This allows for improved cooling capacities and more efficient use of space. Secondly, they operate at lower noise levels, as there are no fans required for cooling. Finally, they can be configured to operate in harsh environments, where traditional air cooling solutions would be ineffective.

Applications of Liquid Cold Plates

Liquid cold plates find use in a wide range of applications, including power electronics cooling, data center cooling, and medical imaging. They are also increasingly being employed in automotive applications, as electric vehicles require efficient cooling solutions to ensure the longevity and efficiency of the battery system.

Conclusion

Liquid cold plates are crucial for ensuring the efficient and reliable cooling of high-powered electronics. The choice of liquid cold plate manufacturer is critical in ensuring quality, performance, and longevity of the cooling solution. With proper consideration of key factors such as product quality, manufacturing capabilities, customization options, and technical support, users can ensure they select the best manufacturer for their requirements.