The Importance of Airflow in Heat Sink Cooling

When it comes to cooling electronic components through a heat sink, there are two main methods for directing airflow: pushing or pulling. This article will explore both options and help you determine which one is better for your specific needs.

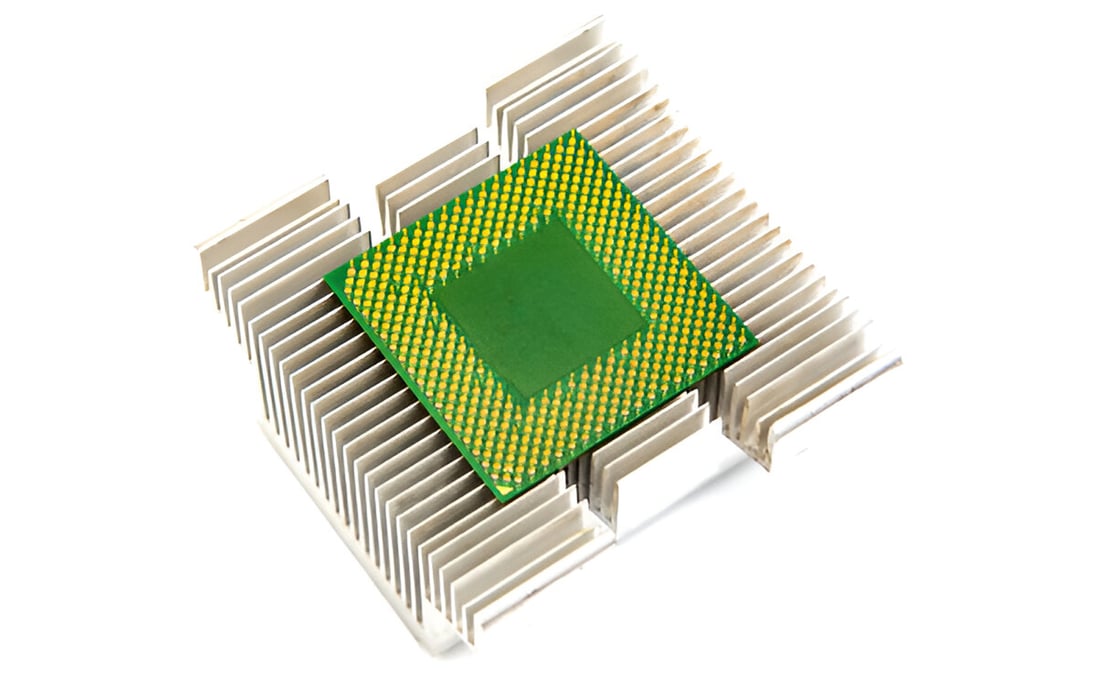

What is a Heat Sink?

A heat sink is a device designed to absorb and dissipate heat away from electronic components. They are made with materials that have high thermal conductivity, such as aluminum or copper, and often have fins or other protrusions to increase surface area and improve airflow.

The Importance of Airflow

The effectiveness of a heat sink is directly related to the amount of airflow passing over it. Without proper airflow, the heat cannot be effectively dissipated and can lead to overheating and component failure.

Pushing Air Through a Heat Sink

Pushing air through a heat sink involves using a fan or other device to force air through the fins and out the other side. This method creates a positive pressure system, where the air is pushed through the heat sink and out of the system.

The Benefits of Pushing Air

The main benefit of pushing air through a heat sink is that it is more effective at removing heat from the system. This is because the air is forced through the fins and there is less chance for dead spots where heat can accumulate. Additionally, pushing air through a heat sink can prevent dust and other particles from settling and accumulating on the fins.

The Drawbacks of Pushing Air

The main drawback of pushing air through a heat sink is that it can create more noise and vibration than pulling air. Also, the fans used to push the air through the heat sink can consume more power and generate more heat than passive cooling solutions.

Pulling Air Through a Heat Sink

Pulling air through a heat sink involves creating a negative pressure system, where the air is drawn through the fins and out of the system. This method typically involves using a fan or other device to pull the air through the fins.

The Benefits of Pulling Air

The main benefit of pulling air through a heat sink is that it can be quieter and more energy-efficient than pushing air. This is because fans used for pulling air typically don't need to work as hard as those used for pushing, since the air is naturally drawn through the fins. Also, pulling air through a heat sink can help remove heat from nearby components, since the airflow isn't confined to a specific direction.

The Drawbacks of Pulling Air

The main drawback of pulling air through a heat sink is that it can be less effective at removing heat than pushing air. This is because the air is drawn through the fins and can create dead spots where heat can accumulate. Additionally, pulling air through a heat sink can allow dust and other particles to settle and accumulate on the fins.

Which Method is Better?

The decision to push or pull air through a heat sink ultimately depends on your specific needs. If removing heat quickly and efficiently is the top priority, pushing air may be the better option. If energy efficiency and low noise levels are more important, pulling air may be the better choice.

Conclusion

Airflow is essential to the effectiveness of a heat sink, and the choice to push or pull air should be based on your specific needs and priorities. Whether it's for cooling a PC, a power supply unit, or other electronic components, understanding the differences between pushing and pulling air through a heat sink can help you make the right choice.