How can I make my heat sink more effective??

Heat sinks are important components of many electronic systems, as they help dissipate the heat generated by semiconductors and other high-power components. Without an effective heat sink, electronic devices can overheat, reducing their performance and potentially damaging them. Fortunately, there are several strategies you can use to make your heat sink more effective. Here are ten approaches worth considering:

1. Choose a Heat Sink with a Larger Surface Area

Heat sinks operate by transferring heat from a hot component to the surrounding air. One way to improve heat transfer is to increase the heat sink's surface area. This can be achieved by using a heat sink with more or larger fins. A larger surface area allows for more conductive paths and, thus, a more efficient heat transfer process.

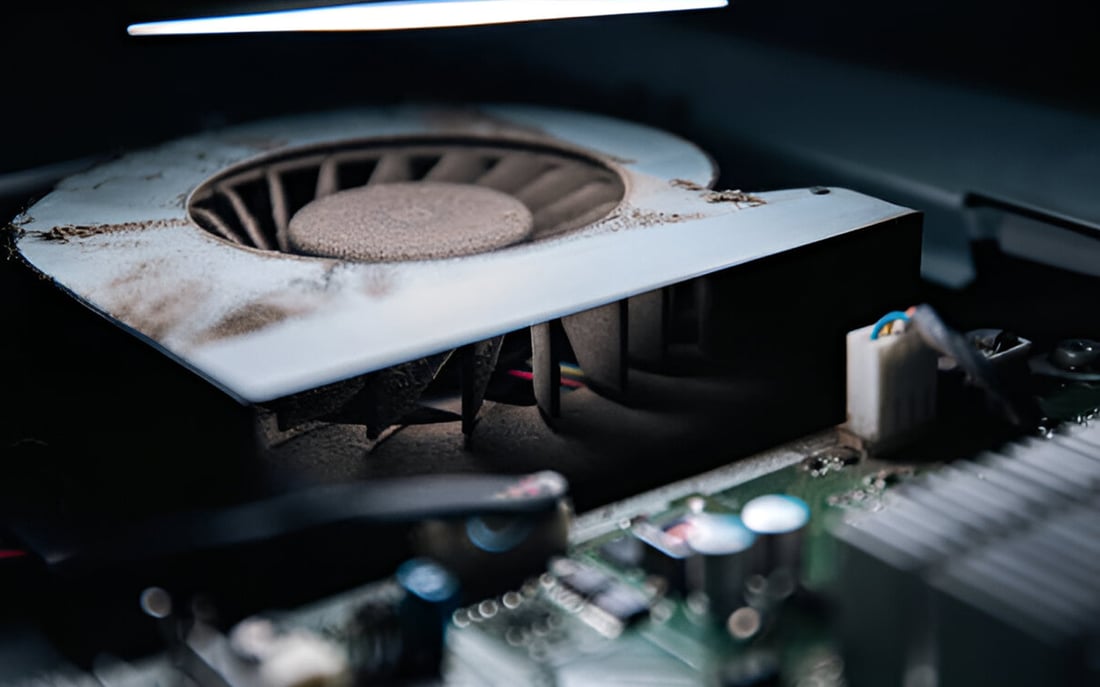

2. Increase Airflow around the Heat Sink

Another way to improve heat transfer is to increase the amount of airflow around the heat sink. This can be accomplished through natural convection, where the heat sink is exposed to the ambient air, or by using forced air cooling, where a fan is used to direct air over the heat sink. Forced air cooling typically provides better results, but requires additional components.

3. Check the Thermal Interface Material

The thermal interface material (TIM) is the substance that fills the microscopic gaps between the heat sink and the component. The quality of the TIM can have a significant impact on the heat sink's effectiveness. Make sure a high-quality thermal paste is properly applied to ensure that the heat sink is making full contact with the component.

4. Optimize the Position of the Heat Sink

The position of the heat sink can affect its effectiveness. If the heat sink is mounted vertically, the natural airflow may be impeded by the fins, reducing the heat transfer rate. Mounting the heat sink horizontally will typically result in better natural convection and heat transfer.

5. Use a Heat Sink with a Higher Thermal Conductivity

The thermal conductivity of a heat sink material determines how well it can transfer heat. Materials such as copper and aluminum have high thermal conductivities, making them ideal for heat sinks. Choosing a heat sink made from a material with a higher thermal conductivity can help improve heat dissipation rates.

6. Add Heat Pipes to the Heat Sink

Heat pipes are typically used in conjunction with heat sinks to improve heat transfer rates. Heat pipes are sealed tubes filled with a fluid that evaporates when heated and condenses when cooled. This cycle helps to transfer heat more efficiently between the heat sink and the component.

7. Use Multiple Heat Sinks

If one heat sink isn't providing enough cooling, you can try using multiple heat sinks. Sparkfun's "Aluminum Heat Sink - 13.8 x 13.8 x 27mm" works well and can help increase the cooling capacity of your system. Just make sure each heat sink is properly positioned to ensure maximum efficiency.

8. Consider Liquid Cooling

Liquid cooling is a highly effective but more complex method of cooling electronics. The basic principle is to use a liquid, typically water, to absorb the heat generated by the component. The heated liquid is then pumped away from the component to an external radiator that dissipates the heat into the surrounding environment.

9. Improve the Component's Thermal Design

Improving the thermal design of the component itself can also help to improve the heat sink's effectiveness. This can include adding thermal vias to the PCB, using low thermal resistance packages, and reducing the thermal resistance of the die-attach material.

10. Increase the Power Density Gradually

If a system is experiencing thermal issues, one common mistake users make is assuming that increasing the cooling capacity will address the issue. However, without changing the underlying thermal design, increasing cooling capacity may be only a temporary fix. A better approach is to gradually increase power density while monitoring temperatures, and then adjust the thermal management accordingly.