Introduction

So what exactly is an extruded copper heat sink? In simplified terms, it is a thermal management solution made of copper that helps to dissipate heat away from an electronic device. Interestingly, copper is the preferred material for heat sink because of its excellent heat conductivity properties. In this article, we explore the prospects of extruded copper heat sink and how it benefits electronic devices.

1. Definition of Extruded Copper Heat Sink

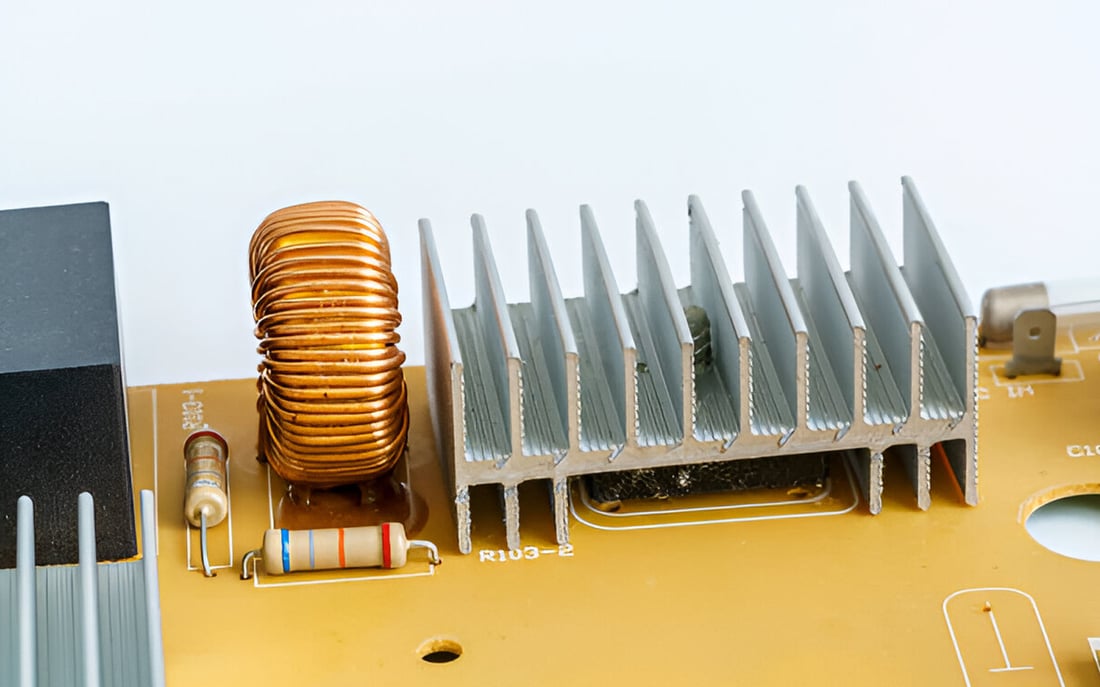

An extruded copper heat sink is a piece of metal with copper as the material of choice. The process of extrusion involves pushing the copper material through a die in a process that shapes and hardens the copper into the desired shape and size. Since copper conducts heat so well, the heat sink can then take heat away from the electronic device and dissipate it into the air.

2. Capability to Control Temperature

One of the critical functions a heat sink is to control the temperature of the electronic device. Copper is the best material to use in this case because of its ability to conduct heat. It helps to remove the heat from the source to a place where air can help in dissipating it. This capability ensures that the electronic device operates optimally without overheating by ensuring that the temperature remains within the recommended range.

3. Design Flexibility

Extruded copper heat sinks have flexible design options. The process of extrusion allows the manufacturer to produce heat sinks with different shapes, sizes, and geometries with ease. This flexibility in design makes it possible to customize the heat sink for specific devices to ensure optimum performance concerning thermal management. The designs can include fins with different heights and patterns to enhance heat dissipation.

4. Durability and Longevity

Copper is a robust and durable material, making it the preferred choice in heat sinks. Due to the process of extrusion that is used in making the heat sinks, it enhances the copper's strength and durability, ensuring they can withstand the operating conditions of electronic devices. With proper maintenance and handling, extruded copper heat sinks can last for a long time without the need for replacement.

5. High Thermal Conductivity

Copper is a highly conductive material that can dissipate heat fast, making it the ideal material for a heat sink. Extruded copper heat sinks have excellent thermal conductivity properties that allow them to take away large amounts of heat from the electronic device, ensuring the device maintains the temperature range levels. Copper has a high thermal conductivity coefficient, making it five times better than aluminum.

6. Cost-Effectiveness

Copper heat sinks offer a cost-effective solution to thermal management due to their low manufacturing costs. The copper material used in extrusion is easily available, and the process is straightforward, making the production of heat sinks cost-effective. Additionally, copper heat sinks have a higher thermal conductivity coefficient than aluminum. This property allows the heat sink to have a smaller size than an aluminum heat sink, reducing the material's quantity needed and hence the cost.

7. Availability

Copper is an abundant and readily available material. The material is easily sourced, and the production of copper heat sinks is not a complicated process. This availability warrants that the extruded copper heat sinks are readily available for manufacturers and consumers worldwide. The easy availability translates to reduced manufacturing costs for the manufacturer and affordable prices for consumers.

8. Compatibility

Extruded copper heat sinks are compatible with many electronic devices. They can be customized to fit the required space and shape of the device. Copper material is also highly compatible with printed circuit boards. The compatibility of extruded copper heat sinks ensures they can be installed in a wide range of devices to provide optimal thermal management.

9. Energy Efficiency

Extruded copper heat sinks are energy-efficient and help to conserve energy. The high thermal conductivity of copper enables the heat sink to dissipate heat from the electronic device, reducing the need for additional cooling. This, in turn, reduces energy consumption while ensuring the device operates efficiently. Using copper heat sinks reduces energy consumption and promotes the conservation of energy.

10. Environmental Friendliness

Extruded copper heat sinks are environmentally friendly compared to other heat sink materials. Copper is a recyclable material, and the process of recycling requires less energy than producing copper from raw materials. Additionally, copper has a lower thermal expansion rate, meaning that the heat sink can withstand temperature changes without warping or cracking, reducing waste and promoting sustainability.