Introduction

Heat sinks are crucial components in electronic devices as they help dissipate excess heat and prevent devices from overheating. They are usually made of materials with high thermal conductivity such as aluminum, copper, and graphite. In this article, we'll explore whether or not aluminum makes a good heat sink and what makes it an excellent choice for heat dissipation.

What is a Heat Sink?

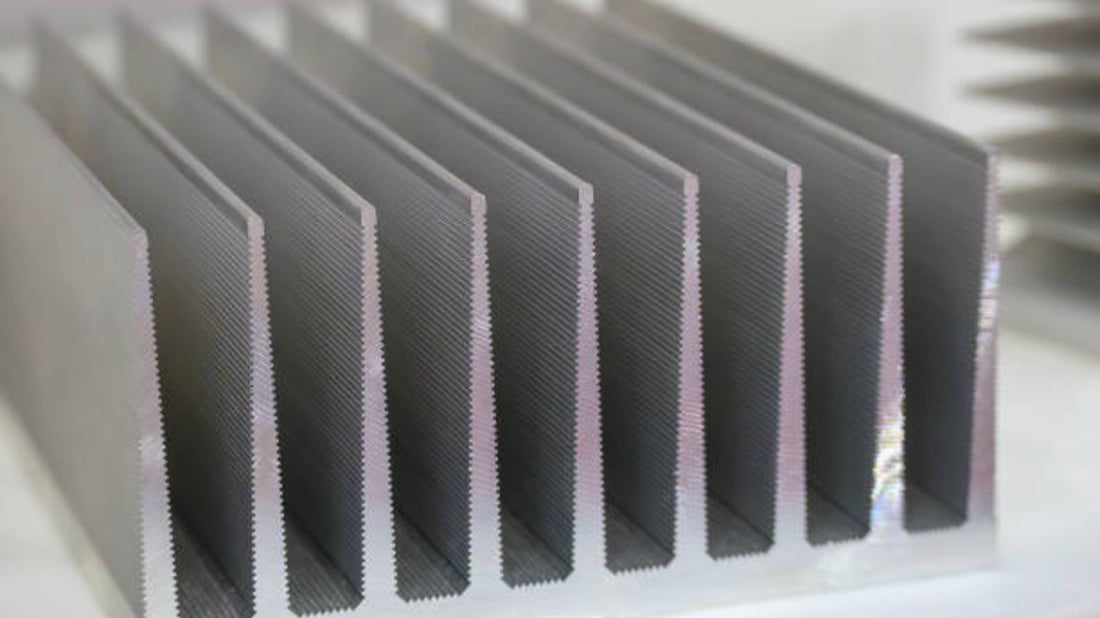

A heat sink is a component in electrical devices that helps to dissipate heat. It is made from materials with high thermal conductivity, and its primary purpose is to transfer heat from electronic components to the surrounding environment. Heat sinks are generally made from metals like aluminum, copper, and steel.

Why Choose Aluminum?

Aluminum is considered one of the best materials for a heat sink due to its high thermal conductivity compared to other metals. It is also lightweight, corrosion-resistant, and has good mechanical properties, making it an ideal choice for many applications. Additionally, aluminum is readily available and has low production costs, making it an economical choice for heat sink manufacturing.

How Does it Work?

When an electronic device runs, it generates heat that needs to be dissipated to avoid overheating and failure. A heat sink attached to the electronic components acts as a conduit and moves the heat away from the components, allowing it to dissipate into the surrounding environment. Aluminum is an excellent conductor of heat, allowing it to transfer heat away from the electronic components quickly and efficiently.

The Different Types of Aluminum Heat Sinks

There are different types of aluminum heat sinks that suit different applications. Some of the most common types of aluminum heat sinks include:

- Extruded aluminum heat sinks

- Bonded fin heat sinks

- Skived fin heat sinks

- Stamped heat sinks

Each type of heat sink has unique features and benefits depending on the application it's being used for.

Factors Affecting Heat Sink Performance

The efficiency of a heat sink depends on various factors, including:

- Surface area

- Heat transfer coefficient

- Thermal conductivity

- Material density

- Material properties

The larger the surface area of the heat sink, the more it will be able to dissipate heat. A higher heat transfer coefficient allows for faster transfer of heat from the source. Thermal conductivity refers to how quickly a material can conduct heat, and higher thermal conductivity means that more heat can be transferred. Material density affects heat sink performance because denser materials tend to have higher thermal conductivity.

The Advantages of Aluminum Heat Sinks

Aluminum has several advantages over other materials as a heat sink, including:

- Superior thermal conductivity

- Lightweight

- Corrosion-resistant

- Low cost

- Easy to manufacture

Due to its excellent thermal conductivity, aluminum heat sinks are highly effective in dissipating heat generated by electronic devices. Also, aluminum is lightweight and has excellent mechanical properties, making it an ideal choice for heat sink manufacturing.

Disadvantages of Aluminum Heat Sinks

Despite its numerous benefits, aluminum heat sinks also have some disadvantages, including:

- Less durable than other materials like copper

- May not be effective when exposed to extremely high temperatures

- Susceptible to damage from rough handling

- May require coatings or treatments to enhance corrosion resistance

Conclusion

Aluminum is undoubtedly an excellent material for heat sinks due to its superior thermal conductivity, lightweight, and corrosion-resistant properties. However, like any other material, it has its drawbacks, and its suitability depends on the specific application required. Proper selection and design of an aluminum heat sink can provide the most effective and efficient heat dissipation solution for electronic devices.