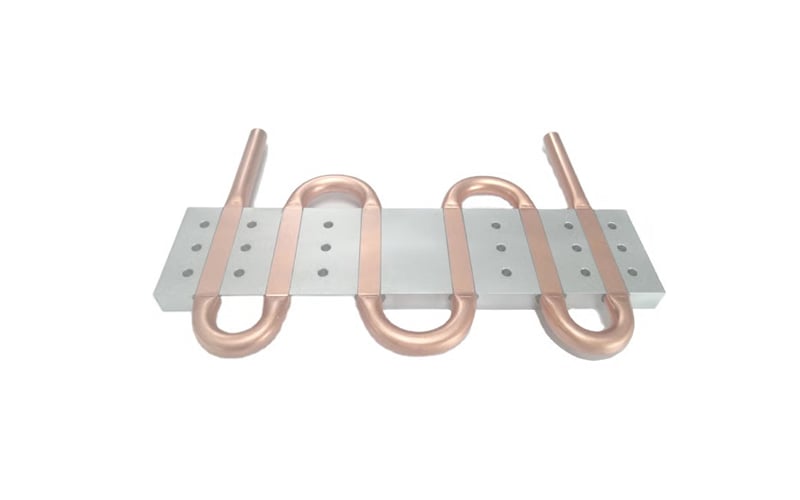

Material Selection for Custom Liquid Cooling Plates

When designing custom liquid cooling plates, one of the most important considerations is the material used. Materials such as copper, aluminum, and stainless steel are commonly used for their conductivity and corrosion resistance.

Thickness and Weight Considerations

The thickness and weight of the custom liquid cooling plates are crucial factors to consider. The thickness affects heat dissipation efficiency, while the weight plays a role in overall system design and performance.

Fluid Flow and Pressure Drop

Efficient fluid flow and minimal pressure drop are essential for optimal cooling performance.

Design Considerations for Custom Liquid Cooling Plates should include the layout of internal channels and flow patterns to achieve this goal.

Surface Finish for Enhanced Heat Transfer

The surface finish of custom liquid cooling plates can greatly impact heat transfer efficiency. Finishes such as microchannel textures or coatings can improve thermal conductivity and overall cooling performance.

Compatibility with Cooling Fluids

Custom liquid cooling plates must be designed to be compatible with various cooling fluids, such as water, glycol, or specialty coolant blends. Materials selection and design features should ensure compatibility and prevent corrosion.

Integration with Existing System Components

Considerations for integrating custom liquid cooling plates with existing system components are essential for seamless operation. Factors such as mounting options, tubing connections, and overall system layout should be carefully planned.

Optimization for Thermal Performance

The primary goal of custom liquid cooling plates is to optimize thermal performance and dissipate heat efficiently. Design considerations should focus on maximizing surface area, fluid flow velocity, and minimizing thermal resistance.

Customization for Specific Cooling Requirements

Custom liquid cooling plates offer the flexibility to tailor designs to specific cooling requirements. Whether for high-performance computing, industrial applications, or electronics cooling, customization options are key for optimal results.

Testing and Validation Processes

Thorough testing and validation processes are crucial for ensuring the performance and reliability of custom liquid cooling plates. Prototypes should undergo rigorous testing to validate thermal performance and fluid dynamics.

Cost Considerations and Return on Investment

Design considerations for custom liquid cooling plates should also include cost analysis and return on investment calculations. Balancing performance requirements with budget constraints is essential for successful implementation.

Quote Inquiry

Contact us