The Purpose of a Copper Heat Sink for Welding

When you are welding, there is a lot of heat generated. This heat can affect the weld on both sides of the metal and potentially distort the metal itself. That's where the copper heat sink comes in. A copper heat sink performs the role of absorbing heat and distributing it, so the heat doesn't affect the weld.

Copper Heat Sinks: Durability and Longevity

Copper heat sinks are highly durable and long-lasting, making them ideal for welding. This material has excellent thermal conductivity, which means it can absorb and conduct heat very effectively. This property of copper facilitates efficient heat dissipation and reduces the risk of the weld overheating.

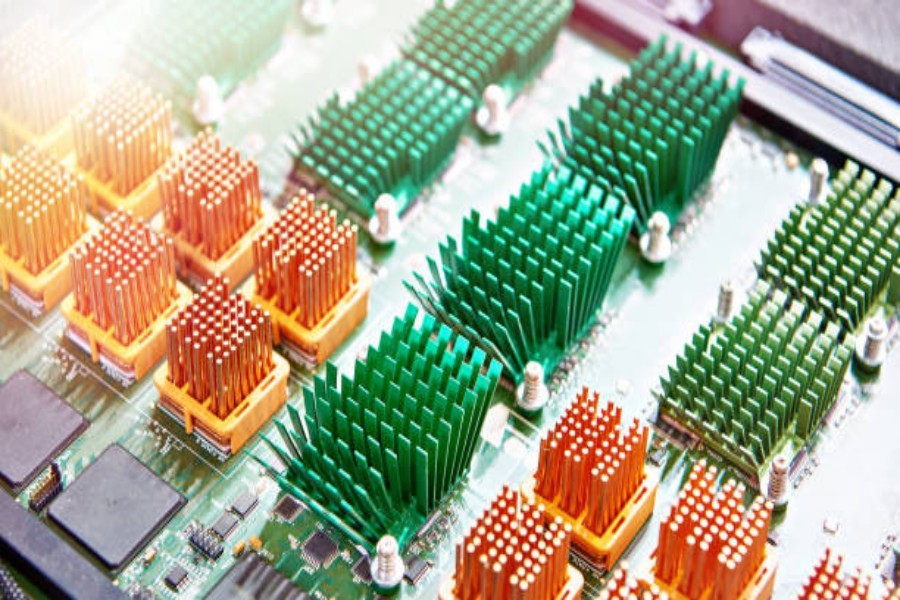

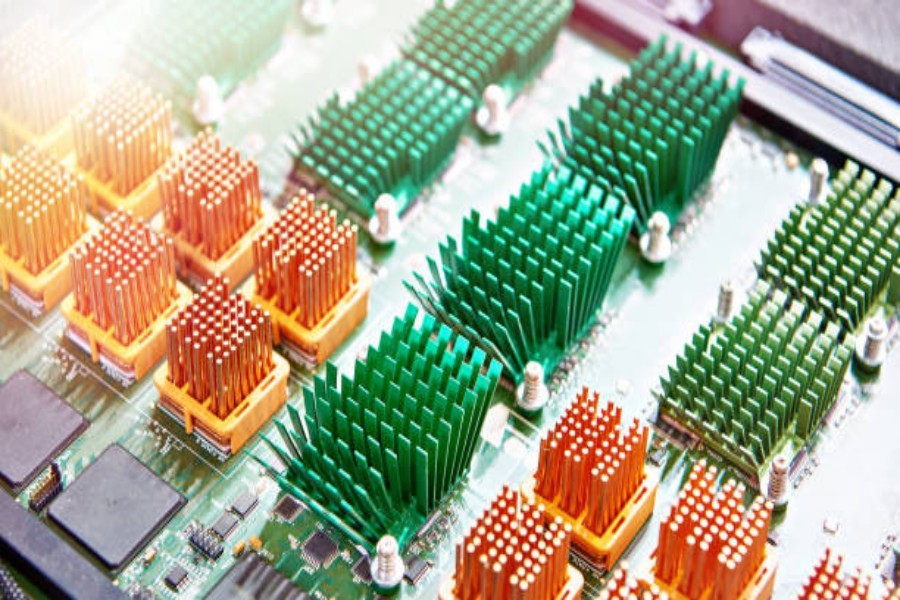

Types of Copper Heat Sinks

Copper heat sinks for welding come in different sizes and shapes. The most common shapes are cylindrical and rectangular copper heat sinks. The size and shape of the heat sink you choose will depend on the welding project you are working on. However, no matter what the size or shape, all copper heat sinks perform the same function: cooling the weld area.

Methods of Using Copper Heat Sinks for Welding

Two main methods of using copper heatsinks for welding are clamping and soldering. Clamping involves holding the heat sink against the workpiece using a clamp or vice. On the other hand, soldering involves fixing the heat sink to the welding gun or torch. The method of choice will depend on the type of welding you are doing and personal preferences.

Advantages of Copper Heat Sinks

One of the biggest advantages of copper heat sinks for welding is their ability to improve the quality of welds. With their excellent heat dissipation properties, copper heat sinks make it possible to achieve clean, uniform, and high-quality welds every time. Additionally, they are easy to use, versatile, and can be incorporated into diverse welding setups.

Factors to Consider when Choosing a Copper Heat Sink

When choosing a copper heat sink for welding, key factors to consider include the size and shape of your welding project, the thickness of the metal you are welding, the type of welding process you are using, and the location of the weld on the metal. The more these factors align with the properties of the copper heat sink, the better the results you will have.

Maintenance of Copper Heat Sinks

Maintaining copper heat sinks involves cleaning them regularly and removing any metal shavings or debris that may settle on the surface. You should also inspect the heat sink for any deformations or damage that may affect its ability to cool the weld area. If you notice any damage, it's best to replace the heat sink immediately.

Cost of Copper Heat Sinks

Copper heat sinks are relatively inexpensive. The cost of the heat sink will depend on the size, shape, and brand. Generally, the more sophisticated the heat sink, the higher the cost. However, it's important to note that copper heat sinks are worth the investment since they help improve the quality of your welds and increase the longevity of your welding equipment.

Where to Find Copper Heat Sinks

You can purchase copper heat sinks for welding from various welding supply stores, online retailers, or distributors. It's important to buy from a reputable seller to ensure you get a high-quality product that meets your specific welding needs.

Conclusion

Copper heat sinks are effective tools for welding beginners and professionals alike. They help protect the weld area from overheating, improve the quality of welds, and increase the longevity of welding equipment. By using copper heat sinks for your welding projects, you can achieve clean, uniform, and high-quality welds every time.

Quote Inquiry