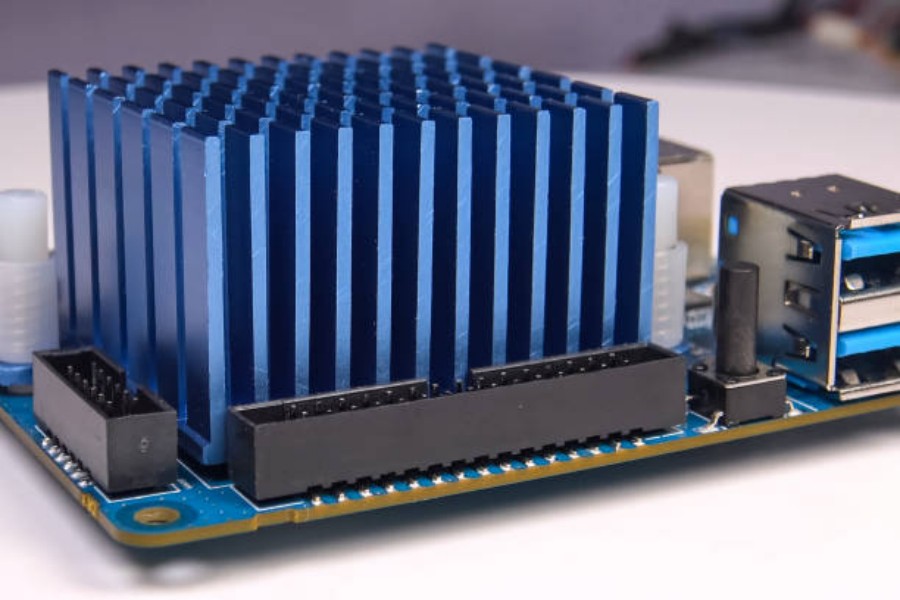

Introduction: What is Copper Foam Heat Sink?

Copper foam heat sink refers to a high-performance thermal management material made from copper foam. This unique material has a cellular structure that offers high porosity, excellent thermal conductivity, and an extensive surface area, all of which make it an ideal heat dissipation solution for various industrial applications.

Benefits of Copper Foam Heat Sink

Here are some of the benefits of using copper foam heat sink:

High Thermal Conductivity

Copper is a material that boasts incredible thermal conductivity properties. With copper foam heat sink, the porosity and cellular structure of the material allow for effective heat dissipation, ensuring that the heat generated by electronic devices is quickly and efficiently transferred to the surrounding environment.

Effective Heat Dissipation

The unique cellular structure of copper foam heat sink allows for a high surface area, which effectively dissipates heat from electronic devices. Additionally, copper foam heat sink is incredibly lightweight, which means that it can efficiently remove heat without adding weight to the device it is attached to.

Improved Reliability and Longevity of Electronic Devices

By effectively dissipating heat from electronic devices, copper foam heat sink helps to reduce thermal stress and prolong the lifespan of the device. This is especially critical in high-temperature environments, where heat can cause critical components to degrade and fail prematurely.

Applications of Copper Foam Heat Sink

Copper foam heat sink is a versatile material that finds applications in various industries. Here are some of the applications of copper foam heat sink:

Electronics

The electronics industry is perhaps the most popular application of copper foam heat sink. It is used to dissipate heat from electronic components such as CPUs, GPUs, and power amplifiers. By reducing thermal stress on these components, copper foam heat sink helps to prolong the lifespan of electronic devices while also improving their performance.

LED Lighting

Copper foam heat sink is also used in LED lighting applications. LEDs generate a significant amount of heat, and copper foam heat sink ensures that this heat is efficiently dissipated, preventing the LED from overheating and prematurely failing. Additionally, copper foam heat sink helps to improve the overall energy efficiency and lifespan of LED lighting.

Automotive Industry

Copper foam heat sink finds application in the automotive industry, where it is used to dissipate heat from engine controls, power electronics, and battery management systems. By reducing the heat generated by these components, copper foam heat sink helps to improve the efficiency and performance of vehicles while also prolonging their lifespan.

Solar Energy

Copper foam heat sink is also used in solar energy applications. Solar panels generate heat when exposed to light, and copper foam heat sink helps to dissipate this heat, preventing damage to the panel. Additionally, copper foam heat sink helps to improve the overall efficiency and lifespan of solar panels.

Conclusion

Copper foam heat sink is an incredible thermal management material that finds application in various industries. Its high thermal conductivity, effective heat dissipation, and ability to improve the reliability and longevity of electronic devices make it an ideal solution for any industry that requires efficient heat dissipation. With its versatility, copper foam heat sink is set to become an even more critical component in a vast range of industrial applications.