Comparing 6061 aluminum heat sinks to other alloys: A Comprehensive Analysis

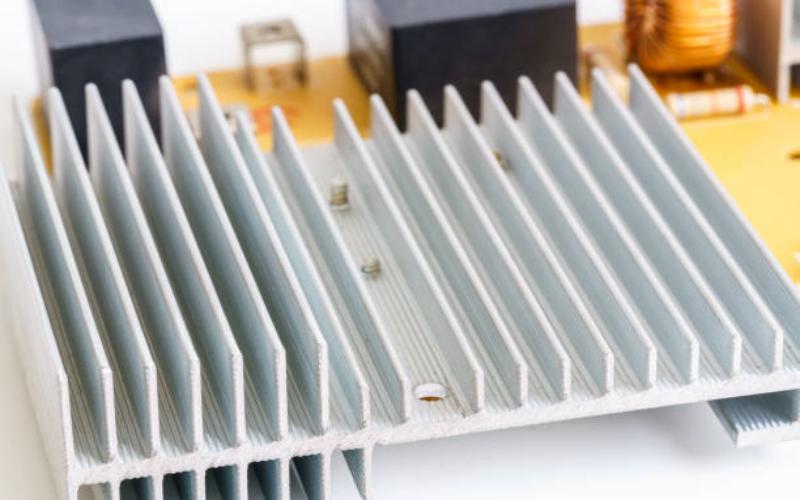

Heat sinks play a crucial role in dissipating heat generated by electronic devices, ensuring their optimal performance and longevity. Among the various materials used for heat sink manufacturing, 6061 aluminum is a popular choice due to its exceptional thermal properties and cost-effectiveness. In this article, we will compare 6061 aluminum heat sinks to other alloys, exploring their differences and advantages in different scenarios.

The Versatility of 6061 Aluminum Heat Sinks

6061 aluminum is an alloy composed primarily of aluminum, magnesium, and silicon. This unique combination grants it remarkable properties that make it suitable for a wide range of applications. When used as a heat sink material, 6061 aluminum exhibits excellent thermal conductivity, allowing for efficient heat transfer from the heat source to the environment. Additionally, it offers good corrosion resistance, mechanical strength, and ease of machining, further enhancing its versatility.

Comparing Thermal Conductivity

Thermal conductivity is a crucial factor when evaluating the effectiveness of a heat sink material. It determines how well the heat sink can transfer heat away from the source. In this regard, 6061 aluminum performs admirably, with a thermal conductivity of approximately 167 W/mK. While this value is lower than some other alloys like copper (401 W/mK), it surpasses many common alternatives such as stainless steel (15-20 W/mK) or zinc (116 W/mK).

Considering Cost-Effectiveness

Cost is another crucial aspect to consider when selecting a heat sink material, especially in large-scale production. 6061 aluminum shines in this department, as it offers an excellent balance between performance and affordability. Compared to high-performance alloys like copper or silver, 6061 aluminum is significantly more cost-effective, making it an ideal choice for applications where budget constraints are a concern.

Exploring Corrosion Resistance of 6061 Aluminum Heat Sinks

The ability to withstand corrosion is vital for heat sinks, particularly in environments with high humidity or exposure to corrosive substances. While 6061 aluminum exhibits good corrosion resistance, it may not match the exceptional resistance of certain alloys like stainless steel or titanium. However, proper surface treatments and coatings can significantly enhance its corrosion resistance, making it suitable for a wider range of applications.

Examining Mechanical Strength

Heat sinks often need to endure mechanical stress, whether from mounting, transportation, or accidental impacts. Here, 6061 aluminum offers a great advantage with its excellent mechanical strength. Its high tensile strength (up to 310 MPa) and good yield strength (up to 276 MPa) ensure the heat sink remains structurally intact even under demanding conditions. This makes 6061 aluminum a reliable choice for industrial and automotive applications.

Considering Machinability

Machinability plays a crucial role in the manufacturing process of heat sinks. The ease with which a material can be shaped, drilled, or cut affects production time and costs. 6061 aluminum is known for its excellent machinability, allowing for efficient manufacturing processes without compromising the final product's quality. This characteristic, combined with its affordability, makes 6061 aluminum a top choice for heat sink manufacturers.

Understanding Weight Considerations

In certain applications, weight can be a critical factor. 6061 aluminum excels in this aspect, as it is a lightweight material while still offering impressive strength. When compared to heavier alternatives like copper or brass, 6061 aluminum provides a significant advantage, especially in applications where weight reduction is vital, such as aerospace or portable electronic devices.

Examining Electrical Conductivity

While heat sinks primarily focus on thermal conductivity, electrical conductivity can also play a role in certain applications. 6061 aluminum possesses moderate electrical conductivity, making it suitable for applications where electrical grounding or dissipation of electrical charges is necessary. However, it is important to note that highly conductive materials like copper or silver may be more suitable for applications with specific electrical requirements.

Comparing Surface Finishes

The surface finish of a heat sink can affect its performance and aesthetics. 6061 aluminum offers a variety of surface finishing options, including anodization, painting, or powder coating. These finishes not only enhance the heat sink's appearance but also provide additional corrosion resistance and improve thermal performance by optimizing the surface's emissivity. This flexibility in surface finishes further contributes to the appeal of 6061 aluminum heat sinks.

Considering Environmental Impact

As the world becomes increasingly conscious of environmental sustainability, the impact of materials used in manufacturing processes is gaining attention. 6061 aluminum is a recyclable material, making it an environmentally friendly choice. Its low melting point also reduces energy consumption during recycling compared to certain alloys like stainless steel. By opting for 6061 aluminum heat sinks, manufacturers can align themselves with eco-friendly practices without compromising performance.