The Importance of aluminum heat sinks

Aluminum heat sinks play an essential role in electronic devices, especially those that produce a substantial amount of heat. They are critical components in electronic manufacturing, and without them, devices would overheat and breakdown, leading to permanent damage. Aluminum heat sinks are efficient at absorbing and dissipating heat, making them the perfect material for cooling electronic components. They have become a standard component in most electronic devices, from smartphones to high-end computers, and understanding their function and importance is crucial.

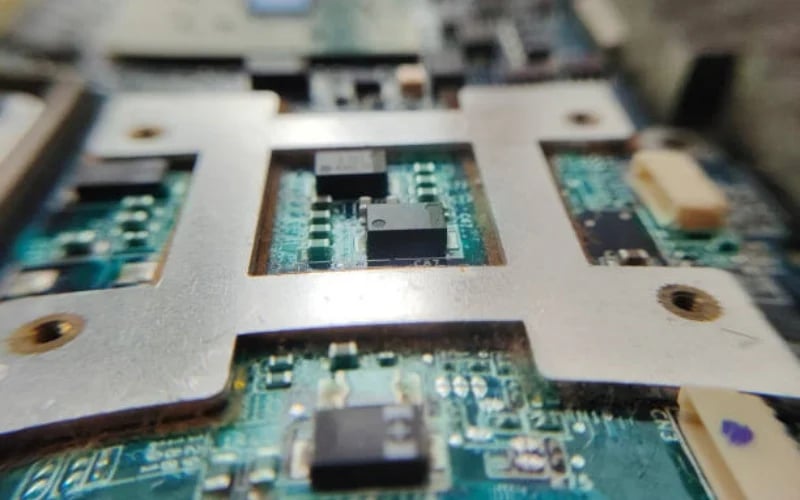

What is an Aluminum Heat Sink?

An aluminum heat sink is a thermal management mechanism that is designed to absorb and dissipate heat generated by electronic devices. It is shaped like a metal block with a series of fins that promote air flow and cooling. As electronic devices become more powerful, the amount of heat they generate increases significantly. Heat sinks transfer this heat to the surrounding air, reducing the overall temperature of the device and preventing potential damage. Aluminum heat sinks are widely used in electronic manufacturing due to their availability, low cost, and high performance.

Types of Aluminum Heat Sinks

There are two main types of aluminum heat sinks: active and passive. Active heat sinks use a fan or another mechanism to increase the airflow and improve heat dissipation. Passive heat sinks use natural convection to dissipate heat, making them ideal for smaller or low-power devices. Passive heat sinks are typically smaller and more compact, while active heat sinks are larger but more powerful.

How Does an Aluminum Heat Sink Work?

An aluminum heat sink works through a process called convection. Convection is the transfer of heat from one place to another through the movement of a fluid, in this case, air. When electronic devices generate heat, the heat sink absorbs it, and the heat is transferred from the device to the heat sink. The heat sink then uses its large surface area to conduct heat to the air surrounding it. The heat is dissipated into the air, and cool air replaces it, creating a continuous cycle of heat transfer and dissipation.

Benefits of Aluminum Heat Sinks

Aluminum heat sinks have several benefits, making them ideal for electronic devices. First, they are lightweight and easy to manufacture, making them relatively inexpensive compared to other materials. Second, they can withstand high temperatures without melting or warping, ensuring the longevity of electronic devices. Third, they provide excellent thermal conductivity, which is essential for efficient heat transfer. Finally, aluminum is a highly malleable material, making it easy to shape into different sizes and designs to fit various device types.

Choosing the Right Aluminum Heat Sink

Choosing the right aluminum heat sink for your electronic device can be challenging. Several factors must be considered to ensure optimal cooling. These include the device's power output, the ambient temperature, and the available space inside the device for the heat sink. It is essential to choose a heat sink that matches the power output of the device and has a large enough surface area to dissipate the heat effectively. The ambient temperature also affects the heat sink's performance, with higher temperatures requiring more powerful heat sinks. Finally, the available space within the device must be considered, as larger heat sinks may not fit in smaller devices.

Installation of Aluminum Heat Sinks

The installation of an aluminum heat sink varies depending on the device type. Some devices, such as laptops and smartphones, come with pre-installed heat sinks, while others require aftermarket installation. When installing an aluminum heat sink, it is essential to ensure proper contact between the device and heat sink to promote efficient heat transfer. A thermal interface material, such as thermal paste or thermal pads, is often used to fill any gaps and promote a seamless connection. It is also crucial to ensure proper airflow to the heat sink, as airflow blockages can reduce its performance.

Aluminum Heat Sinks vs. Other Materials

While aluminum heat sinks are widely used, other materials can also be used to manufacture heat sinks. Copper and brass are two materials often used in heat sinks due to their high thermal conductivity. However, they are heavier and more expensive than aluminum. Graphite is another popular material due to its lightweight and low-cost, but it has lower thermal conductivity than aluminum. The choice of material often depends on the device type and its cooling needs.

The Future of Aluminum Heat Sinks

The future of aluminum heat sinks is promising, as the demand for electronic devices continues to rise. The increasing power output of electronic devices requires more efficient cooling mechanisms to prevent overheating and component damage. As a result, new designs and materials are being developed to increase the performance of aluminum heat sinks further. These include advanced cooling technologies such as liquid cooling, which uses water or other fluids to transfer heat away from electronic devices, and thermoelectric cooling, which uses electricity to transfer heat. These technologies have the potential to revolutionize the way we cool electronic devices, making them more efficient and reliable than ever before.

Conclusion

Aluminum heat sinks are an essential component in electronic manufacturing, and their importance cannot be overstated. They play a crucial role in the longevity and efficiency of electronic devices, preventing overheating and permanent damage. Understanding the function and benefits of aluminum heat sinks is crucial for selecting the right heat sink for your device and ensuring optimal performance. As technology continues to advance, the future of aluminum heat sinks looks promising, as new materials and designs are developed to improve their performance further.