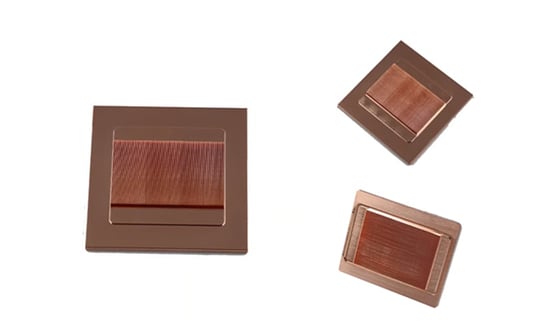

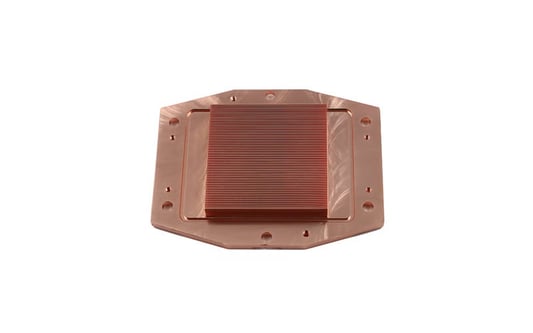

Efficient Heat TransferSingle-piece thermal conduction technology allows for efficient heat transfer in industrial settings. By utilizing materials with high thermal conductivity, heat can be quickly and effectively dissipated, preventing overheating and potential damage to sensitive components.Improved ReliabilityThe use of single-piece thermal conduction components can lead to improved reliability in industrial machinery. By ensuring that heat is evenly distributed and dissipated, the risk of hotspots and component failure is greatly reduced, ultimately increasing the overall lifespan of the equipment.Compact DesignSingle-piece thermal conduction solutions are known for their compact design, making them ideal for applications where space is limited. These components can be integrated seamlessly into existing systems without adding bulk, providing a more streamlined and efficient setup.Cost-Effective SolutionIn many cases, single-piece thermal conduction technology can offer a cost-effective solution for industrial heat management. By reducing the need for complex cooling systems and expensive maintenance, businesses can save money in the long run while still benefiting from reliable heat dissipation.Enhanced PerformanceBy maintaining optimal operating temperatures, single-piece thermal conduction components can help enhance the performance of industrial machinery. This can lead to increased productivity, improved efficiency, and better overall output in manufacturing processes.Customizable OptionsOne of the key advantages of single-piece thermal conduction technology is its customizable nature. Manufacturers can tailor these components to meet specific requirements, ensuring that they are perfectly suited to the unique needs of a particular industrial application.Long-Term DurabilityWith their robust construction and efficient heat dissipation capabilities, single-piece thermal conduction components are built to last. This durability ensures that industrial machinery can operate reliably over an extended period, reducing the risk of unexpected downtime and costly repairs.Environmental BenefitsSingle-piece thermal conduction technology can also offer environmental benefits by reducing energy consumption. By effectively managing heat within industrial systems, less energy is wasted on cooling, leading to a more sustainable operation overall.Advanced Manufacturing TechniquesThe development of single-piece thermal conduction technology has been made possible by advancements in manufacturing techniques. Through precision engineering and innovative materials, these components can now deliver superior heat management performance in a variety of industrial settings.Future ApplicationsAs the demand for efficient heat management solutions continues to grow, single-piece thermal conduction technology is expected to play an increasingly important role in future industrial applications. With ongoing research and development, these components are likely to become even more versatile and effective in the years to come.Quote Inquirycontact us