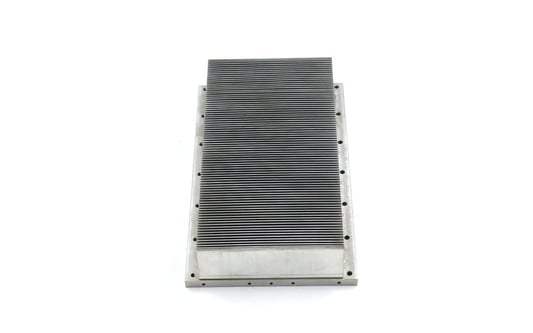

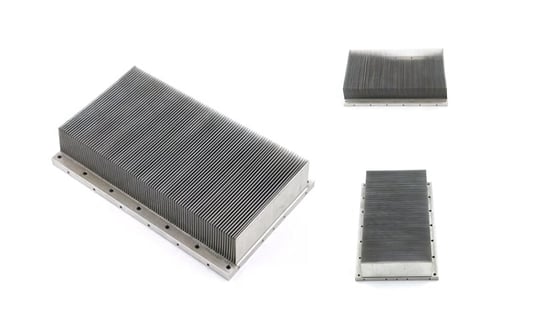

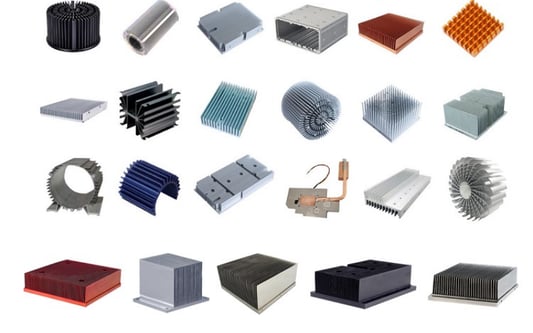

Introduction to Skived heat sink technologySkived heat sink technology is a cutting-edge method used in the manufacturing of heat sinks. This innovative process allows for precise and efficient extraction of heat from electronic devices, ensuring optimal performance and reliability.Benefits of Skived Heat Sink TechnologyOne of the main advantages of skived heat sink technology is its enhanced thermal conductivity. This means that heat is effectively dissipated away from the electronic components, preventing overheating and potential damage.How Skived Heat Sink Technology WorksSkived heat sink technology involves the use of a specialized machine that shaves thin layers of metal from a solid block. This creates a unique fin pattern that increases the surface area for heat dissipation, resulting in improved thermal performance.Applications of Skived Heat Sink TechnologySkived heat sink technology is commonly used in electronic devices such as computers, LED lighting, and power supplies. Its versatility and efficiency make it a popular choice for devices that require effective heat management.Comparing Skived Heat Sink Technology to Other MethodsWhen compared to traditional methods of heat sink manufacturing, skived heat sink technology offers superior thermal performance and a more compact design. This makes it an ideal choice for modern electronics with limited space constraints.Key Features of Skived Heat Sink TechnologyOne of the key features of skived heat sink technology is its ability to create intricate fin designs with high precision. This allows for customized heat sink solutions that are tailored to the specific thermal requirements of the device.The Future of Skived Heat Sink TechnologyAs electronic devices continue to become more powerful and compact, the demand for efficient heat management solutions will only increase. Skived heat sink technology is poised to play a crucial role in meeting these demands and ensuring the reliability of future electronics.Environmental Impact of Skived Heat Sink TechnologyAnother benefit of skived heat sink technology is its eco-friendly nature. By improving the thermal efficiency of electronic devices, energy consumption can be reduced, leading to a smaller carbon footprint and contributing to a more sustainable future.Cost Considerations for Skived Heat Sink TechnologyWhile skived heat sink technology offers many advantages, it is important to consider the cost implications. The initial investment in specialized equipment may be higher, but the long-term benefits of improved thermal performance and reliability can outweigh the upfront expenses.Choosing the Right Skived Heat Sink Technology for Your NeedsWhen selecting a skived heat sink technology for your electronic device, it is essential to consider factors such as thermal conductivity, design flexibility, and cost-effectiveness. By partnering with a reputable manufacturer, you can ensure that your heat sink solution meets your specific requirements.Quote Inquirycontact us