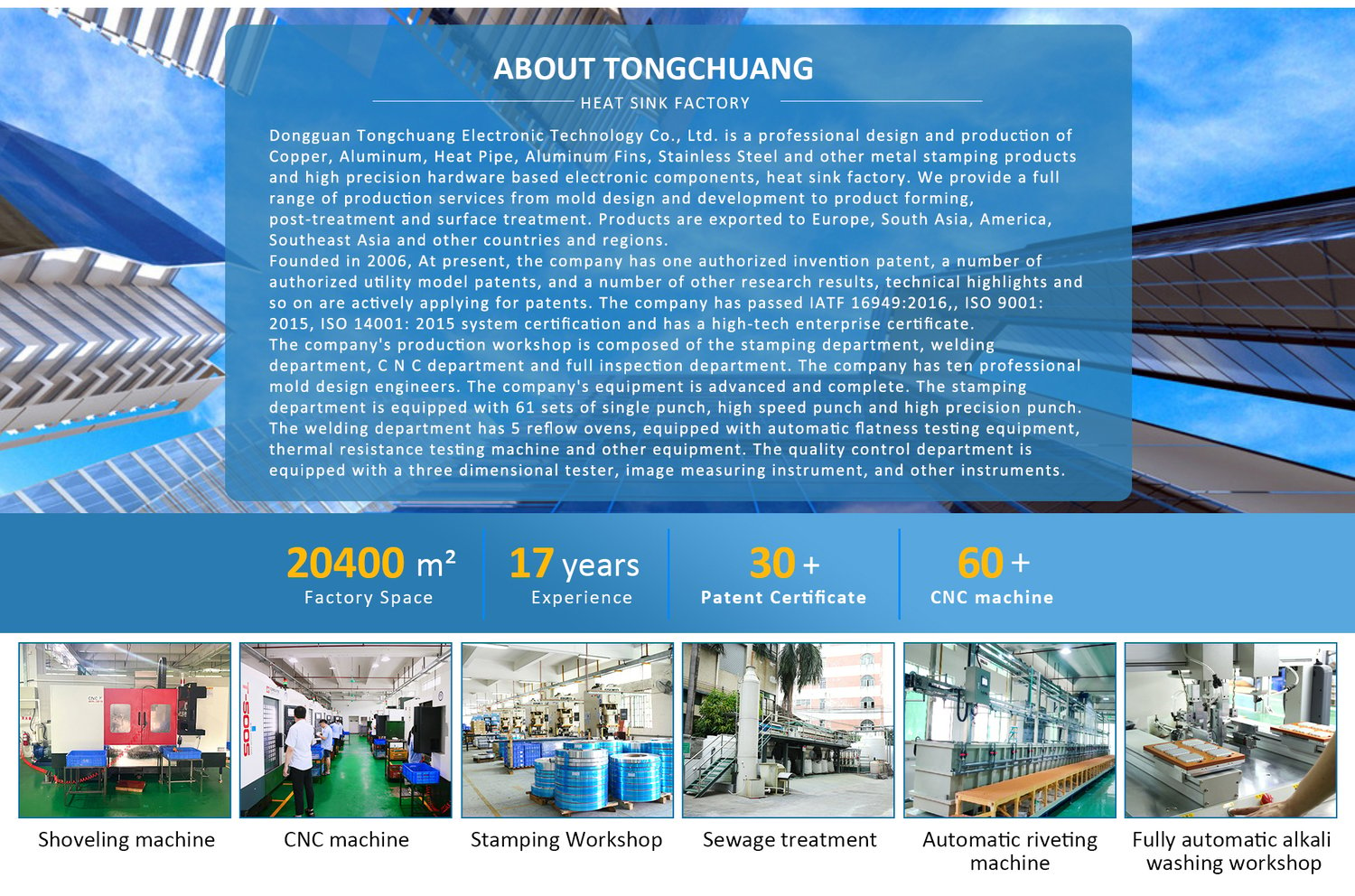

Dongguan Tongchuang Elec.Tech. Co.,Ltd is a professional design and production of Copper, Aluminum, Heat Pipe, Aluminum Fins, Stainless Steel, and other metal stamping products and high precision hardware-based electronic components, and heat sink factory. We provide a full range of production services from mold design and development to product forming, post-treatment and surface treatment. Products are exported to Europe, South Asia, America, Southeast Asia and other countries and regions.

Material:Aluminum/Copper

Tolerance:Customer Requested

Flatness:Customer Requested

Surface Treatment:

Aluminum:Anodizing/Conversion Coating/Nickel Plating

Copper:Anti-Oxidation/Nickel Plating

Cold forged heat sinks are a type of heat sink that is manufactured using metal cold forging technology. This process is used to create high-strength and high-precision parts. Unlike traditional hot forging processes, cold forging is carried out at room temperature, eliminating the need to heat metal materials to high temperatures. The resulting parts have higher density, strength, wear resistance, and surface quality.

| Place of Origin: | Dongguan, China (Mainland) | OEM: | Yes |

| Process: | Cold Forging | Cooling type | Passive |

| Material: | Aluminum | Shape: | Round |

| Application: |

COB LED Down Light |

Finish: |

Anodized Black |

| Extra process: |

CNC Machining |

A. The LED cold forging COB heat sink is constructed from pure aluminum, with the blade able to be 0.8mm thick to maximize the heat radiation surface area of the product. The integrated heat sink, with the same volume and shape, can be utilized for dissipating heat from higher power products, and is lighter in weight, resulting in reduced transportation costs.

B. The thermal conductivity of the same integrated die-casting product material is only 96m. K, and the blade should not be too thin to increase the weight of the product. The surface of die-casting products cannot be anodized, but can only be painted, which will affect heat dissipation.

C. The thermal conductivity coefficient of automotive aluminum profiles is only 136-196m. K, and the split heat sink of aluminum profiles has a significant impact on heat conduction, resulting in only about 60% of the heat dissipation capability of the same type of integrated products. When two cold extruded one-piece heat sinks of the same volume and shape are used on products with the same power, the one-piece heat sink temperatures are approximately 5-6 degrees lower, significantly extending product life.

Yes, send us the drawing and surface treatment requirements, our engineer will evaluate your drawing and give you a quotation.

Yes, we will not release your design to third party unless with your permission. And we can sign the NDA before you send the drawing.

We will charge the tooling cost, but the tooling cost can be refunded when mass production.

MOQ will be set according to your product and drawing requirements, but generally we will not set MOQ.

We can provide sample production, and the mass production will be carried out after the sample is confirmed to you.

Please rest assured that all our products are QC inspected and accepted with inspection report before delivery and generally there will no non-conformance; in case of non- conformance, please contact us immediately, take some pictures, we will check on the problems and have them reworked or repaired at the first time , the resulting transportation costs borne by our company.