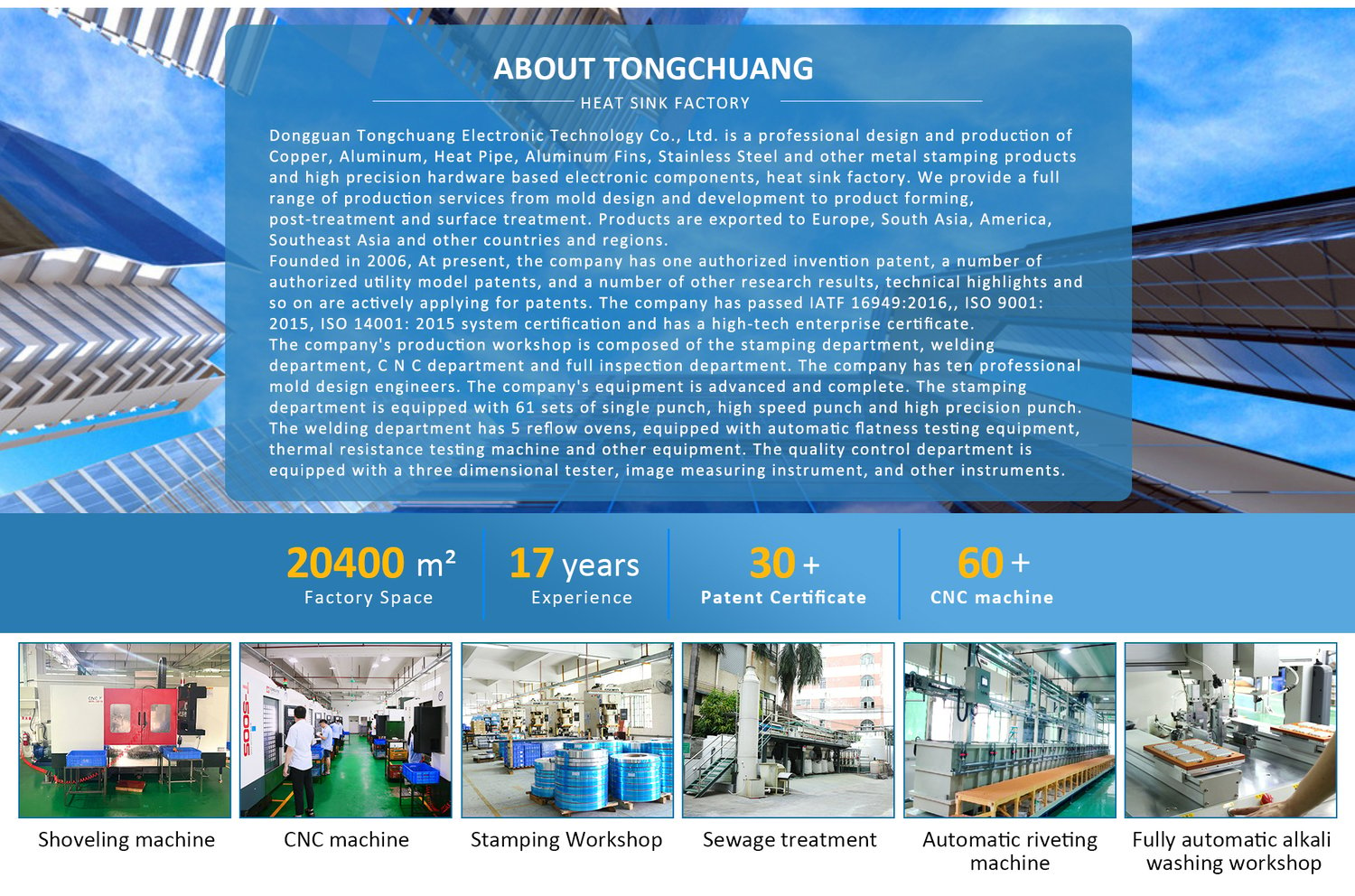

Dongguan Tongchuang Elec.Tech. Co.,Ltd is a professional design and production of Copper, Aluminum, Heat Pipe, Aluminum Fins, Stainless Steel, and other metal stamping products and high precision hardware-based electronic components, and heat sink factory. We provide a full range of production services from mold design and development to product forming, post-treatment and surface treatment. Products are exported to Europe, South Asia, America, Southeast Asia and other countries and regions.

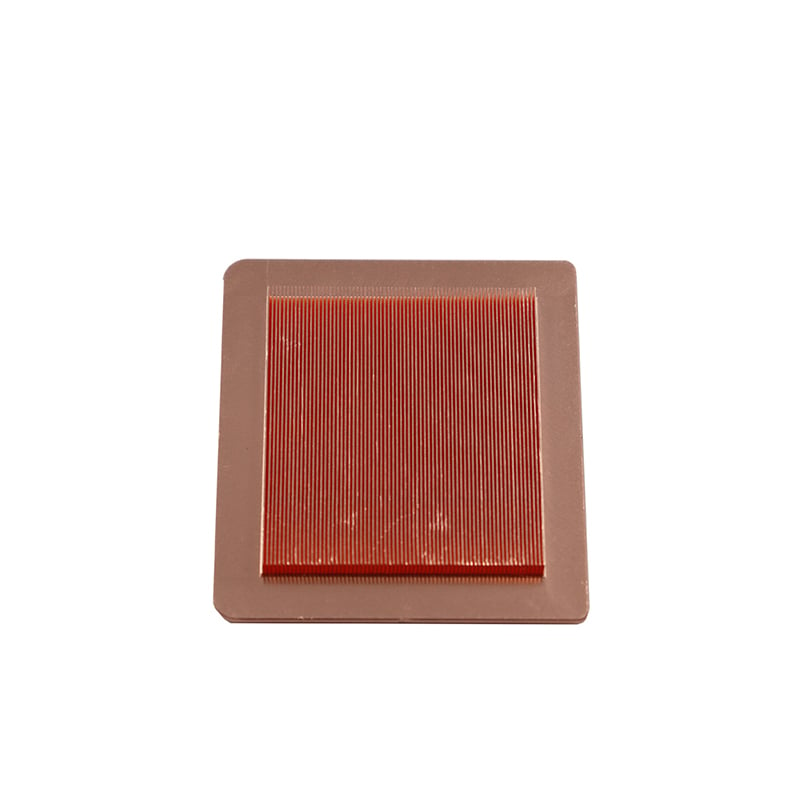

Material: Aluminum/Copper

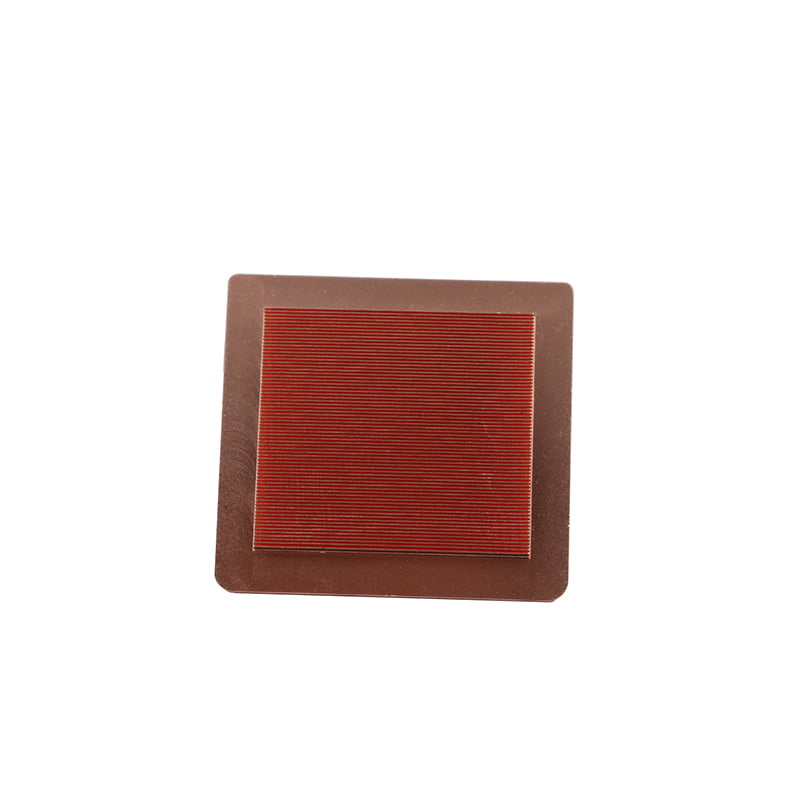

Process: Skiving

Tolerance: Customer Requested

Flatness: Customer Requested

Surface Treatment:

Aluminum: Anodizing/Conversion Coating/Nickel Plating

Copper: Anti-Oxidation/Nickel Plating

Our CNC machined heat sinks are the perfect solution for effectively dissipating heat from electronic components, ensuring optimal performance and longevity. Crafted with precision using advanced machining techniques, these heat sinks offer superior thermal management capabilities, making them an ideal choice for a range of applications.

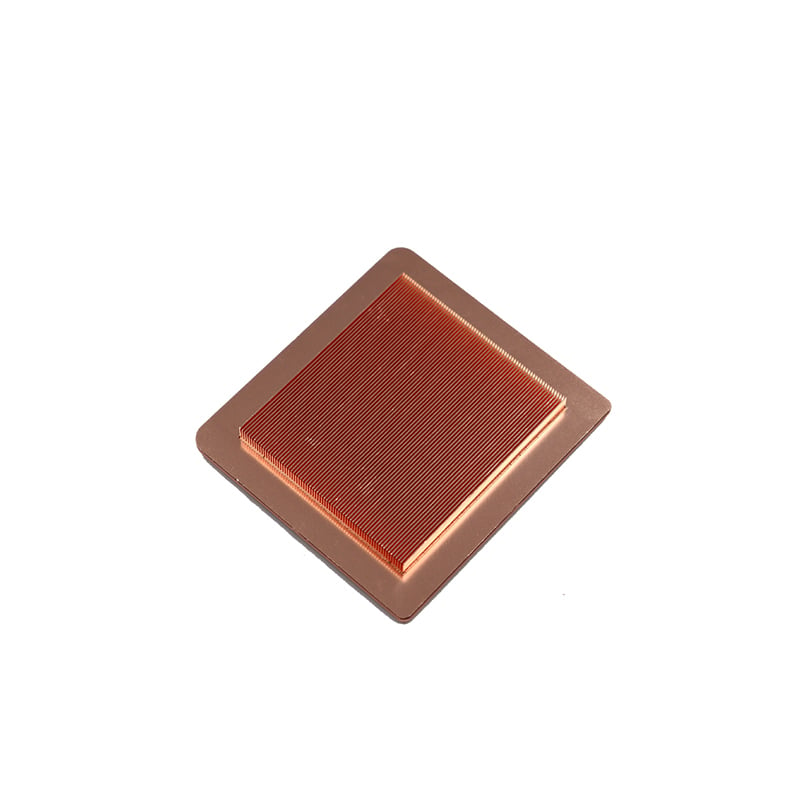

Designed to maximize heat transfer, our CNC machined heat sinks are crafted from high-quality materials that exhibit excellent thermal conductivity. Whether you require aluminum, copper, or another material, we have a wide selection to meet your specific needs. These materials not only dissipate heat efficiently but also offer excellent durability and corrosion resistance.

With our state-of-the-art CNC machining capabilities, we can create heat sinks in a variety of shapes and sizes, ensuring a perfect fit for your specific application. Our expert design team works closely with you to understand your requirements and create a heat sink that meets your exact specifications. From complex geometries to intricate patterns, we can bring your design ideas to life.

The fin design of our CNC machined heat sinks is carefully engineered to maximize the surface area in contact with the air, allowing for efficient heat dissipation. This optimized design ensures that heat is quickly and effectively transferred away from the electronic components, preventing overheating and maintaining their optimal performance.

Our CNC machined heat sinks find applications in a wide range of industries. From electronics and telecommunications to automotive and aerospace, our heat sinks provide reliable cooling solutions for various electronic devices and systems. Whether you need heat sinks for power amplifiers, LED lighting, or computer processors, we have the expertise to deliver the perfect solution.

Backed by 17 years of experience in the industry, we have perfected our manufacturing process to ensure the highest quality heat sinks. From material selection to CNC machining and finishing, every step is meticulously carried out by our skilled technicians. We strictly adhere to industry standards and conduct rigorous quality control checks to deliver heat sinks that meet or exceed your expectations.

With our OEM and ODM services, we can tailor our CNC machined heat sinks to meet your specific requirements. Whether you need custom dimensions, unique fin designs, or special surface treatments, our team can work closely with you to develop the perfect solution. We pride ourselves on our ability to provide customized products that perfectly align with your needs.

Equipped with over 60 CNC machines, our manufacturing facility has the capacity to handle large-scale production while maintaining precision and efficiency. This allows us to meet your demands for CNC machined heat sinks in a timely manner, ensuring quick turnaround times and on-time delivery. Our extensive machine lineup enables us to handle projects of varying complexities with ease.

We understand the importance of delivering heat sinks that perform flawlessly in demanding environments. That's why we implement strict quality control measures throughout our manufacturing process. Our team of experienced quality control professionals conducts thorough inspections and tests to ensure that each heat sink meets the highest standards of performance and reliability.

At our company, we prioritize customer satisfaction above all else. We are dedicated to providing exceptional customer support and service at every stage of your project. From initial design discussions to after-sales support, our team is committed to addressing your concerns, answering your questions, and ensuring your complete satisfaction with our CNC machined heat sinks.

Yes, send us the drawing and surface treatment requirements, our engineer will evaluate your drawing and give you a quotation.

Yes, we will not release your design to third party unless with your permission. And we can sign the NDA before you send the drawing.

We will charge the tooling cost, but the tooling cost can be refunded when mass production.

MOQ will be set according to your product and drawing requirements, but generally we will not set MOQ.

We can provide sample production, and the mass production will be carried out after the sample is confirmed to you.

Please rest assured that all our products are QC inspected and accepted with inspection report before delivery and generally there will no non-conformance; in case of non- conformance, please contact us immediately, take some pictures, we will check on the problems and have them reworked or repaired at the first time , the resulting transportation costs borne by our company.