Introduction to Skived Heat Sink

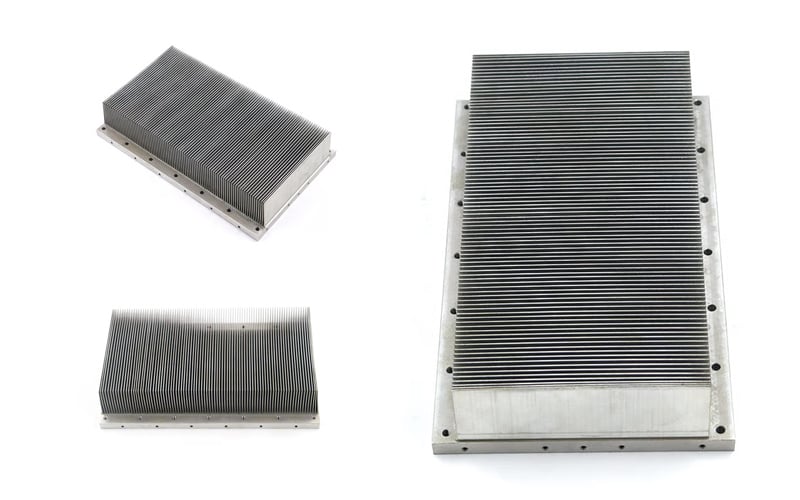

A skived heat sink is a type of heat sink that is manufactured by cutting a block of material in thin layers, which are then folded to create the final product. This unique manufacturing process allows for high efficiency in heat dissipation and is commonly used in electronics to cool down components.

Working Principle of Skived Heat Sink

The skived heat sink works by maximizing the surface area in contact with the air. This increased surface area helps in quickly dissipating the heat generated by electronic components. The thin layers of the heat sink also provide better thermal conductivity, ensuring efficient heat transfer.

Materials Used in Skived Heat Sink

Skived heat sinks are typically made from materials like aluminum, copper, or a combination of both. These materials offer high thermal conductivity, making them ideal for dissipating heat quickly. Copper, in particular, is known for its excellent thermal properties.

Advantages of Skived Heat Sink

One of the main advantages of a skived heat sink is its high efficiency in heat dissipation. The unique manufacturing process allows for precise design customization, leading to better thermal performance. Skived heat sinks are also lightweight and cost-effective, making them a popular choice in the electronics industry.

Applications of Skived Heat Sink

Skived heat sinks are commonly used in electronic devices such as computers, LED lighting, power supplies, and automotive electronics. They are also found in applications where space is limited but efficient heat dissipation is crucial.

Installation of Skived Heat Sink

Installing a skived heat sink is a straightforward process. The heat sink is typically attached to the electronic component using thermal interface materials like thermal paste or pads. Proper installation ensures maximum contact between the heat sink and the component for optimal heat dissipation.

Factors to Consider When Choosing a Skived Heat Sink

When selecting a skived heat sink for your application, it is important to consider factors such as the power dissipation requirements, available space, material compatibility, and thermal resistance. By choosing the right heat sink, you can ensure efficient cooling of your electronic components.

Maintenance of Skived Heat Sink

To maintain the optimal performance of a skived heat sink, regular cleaning and maintenance are essential. Dust and debris can accumulate on the surface of the heat sink, obstructing airflow and reducing its effectiveness. Cleaning the heat sink with compressed air or a soft brush can help in preserving its efficiency.

Future Trends in Skived Heat Sink Technology

With the increasing demand for high-performance electronic devices, the use of skived heat sinks is expected to continue to grow. Advancements in manufacturing techniques and materials will further improve the efficiency and effectiveness of skived heat sinks, making them an integral part of modern electronics cooling solutions.

Conclusion

In conclusion, a skived heat sink is a versatile and efficient cooling solution for electronic components. Its innovative design and high thermal conductivity make it an ideal choice for various applications. Understanding how skived heat sinks work and their benefits can help in selecting the right cooling solution for your electronic devices.