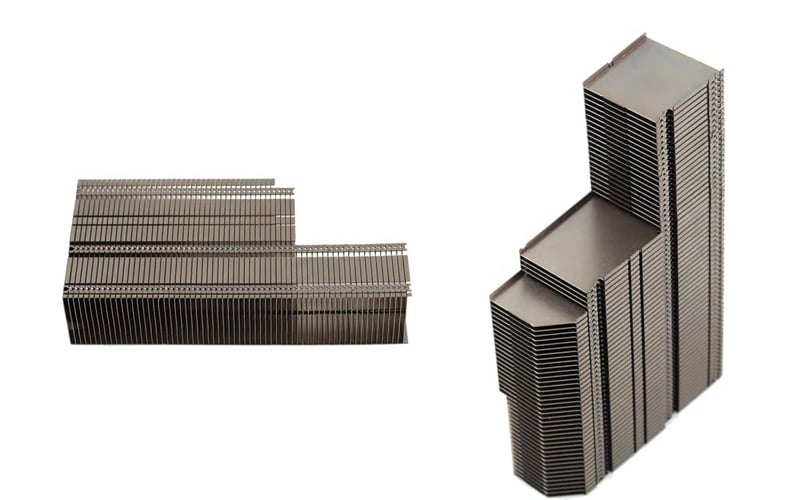

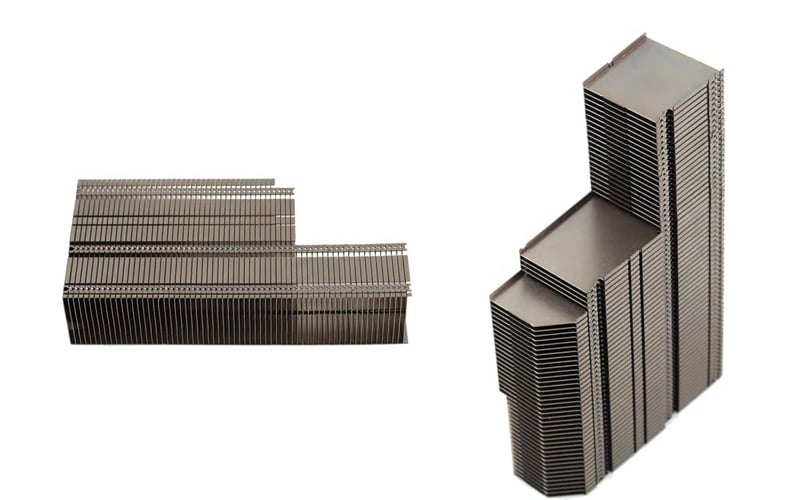

A LED stamping heat sink is a crucial component in LED lighting systems, designed to dissipate heat generated by the light source. This process prevents the LED from overheating, ensuring optimal performance and longevity.

How Does LED Stamping Heat Sink Work?

The heat sink utilizes stamped aluminum or copper sheets to quickly transfer heat away from the LED. The increased surface area allows for efficient heat dissipation, reducing the risk of thermal damage to the LED and prolonging its lifespan.

Benefits of LED Stamping Heat Sink

LED stamping heat sinks offer numerous advantages, including improved thermal management, enhanced LED reliability, and increased energy efficiency. Additionally, these heat sinks are lightweight, cost-effective, and environmentally friendly compared to other cooling solutions.

Types of LED Stamping Heat Sink

There are various types of LED stamping heat sinks available, such as passive, active, and integrated heat sinks. Passive heat sinks rely on natural convection to dissipate heat, while active heat sinks utilize fans or liquid cooling systems for enhanced performance.

Factors to Consider When Choosing LED Stamping Heat Sink

When selecting a LED stamping heat sink, consider factors like thermal resistance, material conductivity, size, weight, and design compatibility with the LED lighting system. It is essential to choose a heat sink that meets the specific requirements of your application.

Installation Process of LED Stamping Heat Sink

The installation of a LED stamping heat sink involves mounting the heat sink onto the LED module using thermal adhesive or clips. Proper installation is crucial to ensure optimal heat dissipation and prevent overheating issues that could damage the LED.

Common Issues with LED Stamping Heat Sink

Some common problems associated with LED stamping heat sinks include inadequate thermal conductivity, poor design compatibility, insufficient heat dissipation, and improper installation. These issues can impact the performance and longevity of the LED lighting system.

Future Trends in LED Stamping Heat Sink Technology

As LED technology continues to advance, so does the development of LED stamping heat sink technology. Future trends may include the use of advanced materials, innovative designs, and smart cooling solutions to further enhance the efficiency and performance of LED lighting systems.

Applications of LED Stamping Heat Sink

LED stamping heat sinks are widely used in various applications, such as residential lighting, commercial lighting, automotive lighting, and industrial lighting. These heat sinks play a crucial role in maintaining the optimal operating temperature of LEDs in different environments.

Conclusion

In conclusion, LED stamping heat sinks are essential components in LED lighting systems, providing efficient heat dissipation and thermal management to ensure the reliable performance of LEDs. By understanding the benefits, types, installation process, and future trends of LED stamping heat sinks, you can make informed decisions when selecting and utilizing these heat sinks for your lighting applications.

Quote Inquiry

contact us