The Basics of Skived Heat Sinks

Skived heat sinks are essential components in electronic devices to dissipate heat. They are commonly used in computers, mobile phones, and other electronic devices to prevent overheating. These heat sinks are made from various materials, with aluminum being the most common choice due to its high thermal conductivity.

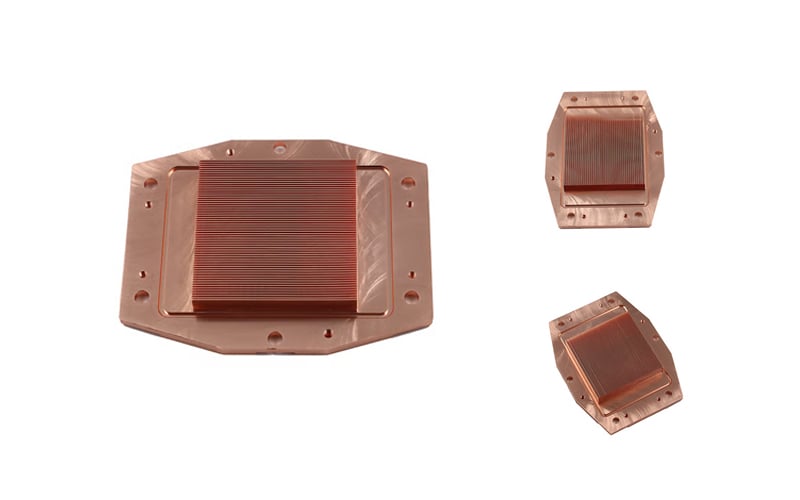

Material Selection in Manufacturing

The manufacturing process of skived heat sinks begins with material selection. Aluminum is the preferred material for its lightweight properties and efficient heat transfer capabilities. Copper is another option for applications requiring higher thermal conductivity, although it is heavier and more expensive than aluminum.

Design and Prototyping

Once the material is selected, the design phase begins. Engineers create detailed designs of the skived heat sink, taking into account factors such as heat dissipation requirements, size constraints, and manufacturing feasibility. Prototyping is often done to test the design before mass production.

Skiving Process Overview

The skiving process involves cutting thin fins into the base material of the heat sink to increase its surface area for better heat dissipation. This process is highly precise and requires specialized equipment such as CNC machines and cutting tools. Skived heat sinks are known for their high efficiency and excellent thermal performance.

CNC Machining and Cutting

CNC machines are used to accurately cut the fins into the base material of the heat sink. This process requires high precision to ensure the fins are uniform in size and shape. Cutting tools with specialized geometries are used to achieve the desired fin profile and maximize heat transfer capabilities.

Finishing and Surface Treatment

After the fins are cut, the heat sink undergoes finishing and surface treatment processes. This may include deburring, polishing, anodizing, or coating to improve the heat sink's durability, corrosion resistance, and overall performance. Surface treatment also enhances the aesthetic appeal of the heat sink.

Quality Control and Testing

Quality control is an essential step in the manufacturing process of skived heat sinks. Inspections are conducted throughout the production process to ensure the heat sinks meet stringent quality standards. Additionally, testing is performed to evaluate the thermal performance and overall effectiveness of the heat sink.

Assembly and Integration

Once the skived heat sinks are manufactured and tested, they are ready for assembly and integration into electronic devices. The heat sinks are carefully installed in proximity to heat-generating components to efficiently dissipate thermal energy and maintain optimal operating temperatures.

Application and Benefits

Skived heat sinks offer several benefits, including improved thermal management, increased energy efficiency, and enhanced reliability of electronic devices. They play a crucial role in preventing overheating and extending the lifespan of components, making them essential in various industries.

Future Developments and Innovations

As technology continues to advance, the manufacturing process behind skived heat sinks is expected to evolve. Innovations in materials, design techniques, and manufacturing processes will further improve the efficiency and performance of heat sinks, meeting the growing demands of the electronics industry.