A PCB heat sink is a vital component used in electronic devices to dissipate heat generated by the components on the printed circuit board (PCB). It is designed to absorb and disperse heat away from sensitive components to prevent overheating and potential damage.

Types of PCB Heat Sinks

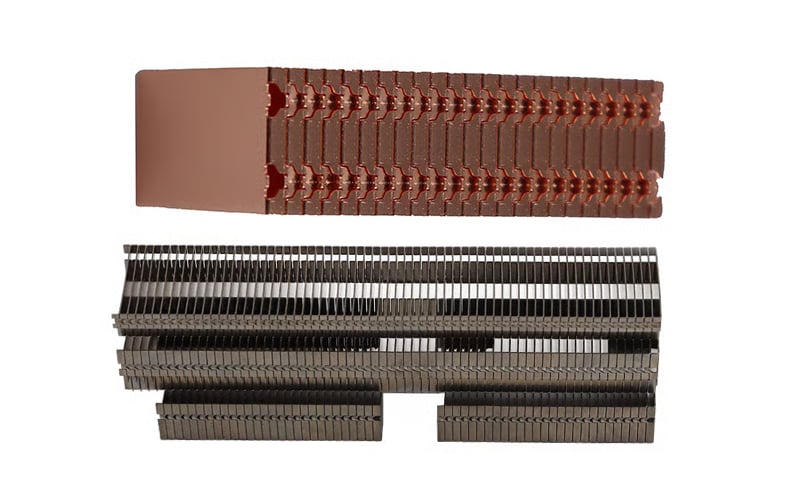

There are several types of PCB heat sinks available, including passive heat sinks, active heat sinks, and finned heat sinks. Passive heat sinks rely on natural convection to dissipate heat, while active heat sinks use fans or other cooling methods. Finned heat sinks have extended fins to increase surface area for better heat dissipation.

Benefits of Using PCB Heat Sinks

Utilizing PCB heat sinks in electronic devices offers numerous benefits, such as improved thermal management, increased component lifespan, and enhanced overall performance. By maintaining optimal operating temperatures, heat sinks help prevent electronic components from overheating and malfunctioning.

Installation of PCB Heat Sinks

Proper installation of PCB heat sinks is crucial to ensure effective heat dissipation. The heat sink should be mounted securely on the component using thermal adhesive or clips to maximize contact and heat transfer. It is essential to follow manufacturer guidelines for correct installation procedures.

Factors to Consider When Choosing a PCB Heat Sink

When selecting a PCB heat sink for a specific application, factors such as thermal resistance, size, material, and weight should be taken into consideration. The heat sink should be compatible with the PCB layout and accommodate any space constraints within the electronic device.

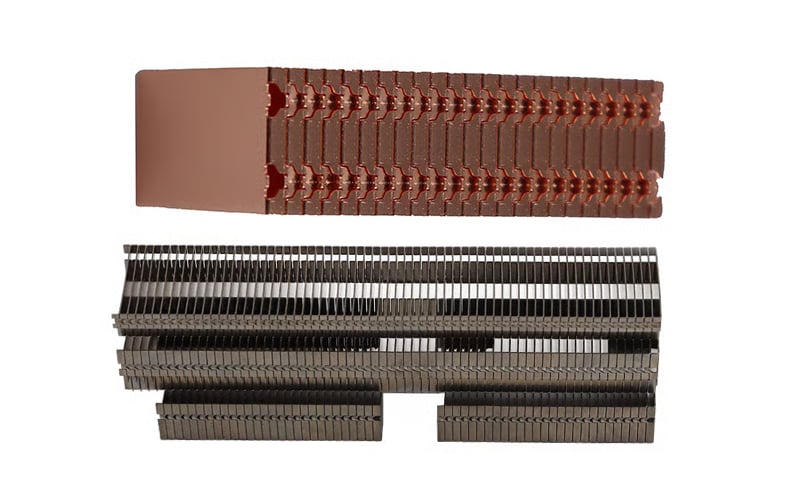

Materials Used in PCB Heat Sinks

PCB heat sinks are typically made from aluminum, copper, or a combination of both materials. Aluminum heat sinks are lightweight and cost-effective, while copper heat sinks offer better thermal conductivity. Some heat sinks also feature heat pipes or vapor chambers for enhanced cooling performance.

Applications of PCB Heat Sinks

PCB heat sinks are commonly used in various electronic devices, including computers, LED lights, power supplies, and industrial equipment. They play a crucial role in maintaining optimal operating temperatures and ensuring the reliability of electronic components in diverse applications.

Advancements in PCB Heat Sink Technology

Over the years, advancements in PCB heat sink technology have led to the development of innovative designs, such as liquid-cooled heat sinks, stacked fin heat sinks, and phase-change heat sinks. These advancements aim to further improve thermal management and efficiency in electronic devices.

Challenges in PCB Heat Sink Design

Designing PCB heat sinks that effectively manage heat while meeting size and weight constraints can present challenges for engineers. Balancing thermal performance with other design considerations, such as cost and manufacturability, requires careful planning and optimization.

Future Trends in PCB Heat Sink Solutions

As electronic devices continue to evolve and demand higher performance levels, the need for advanced PCB heat sink solutions will also increase. Future trends may inclu...

Quote Inquiry

contact us