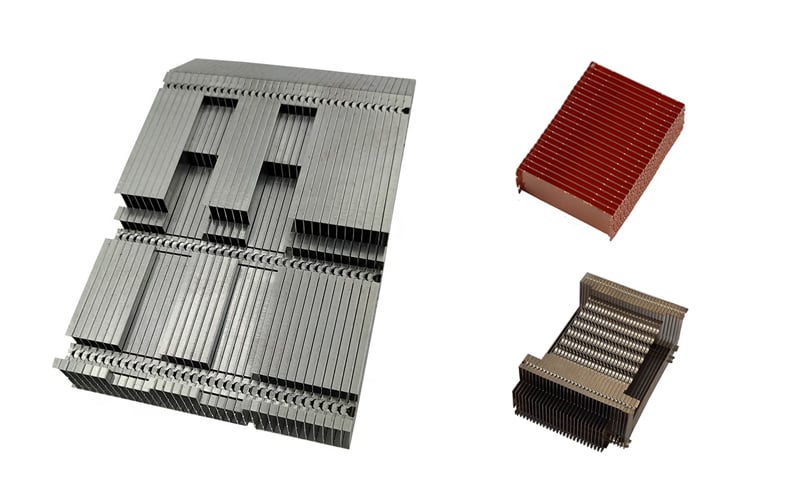

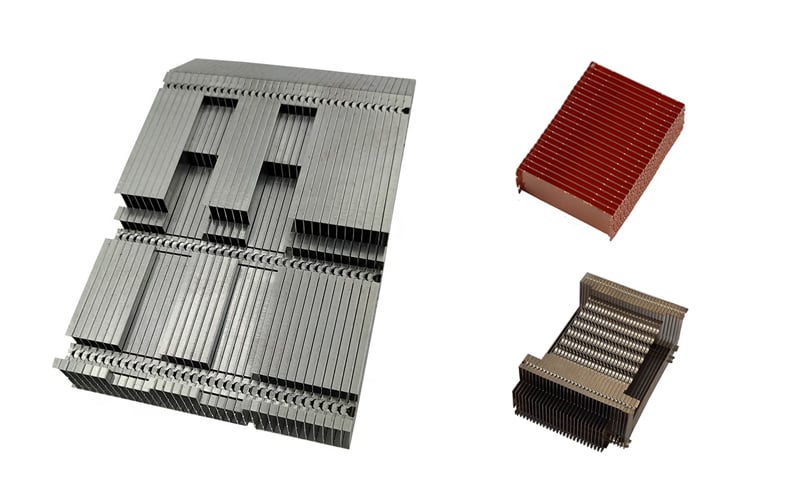

Heat sink precision stamping is a manufacturing process used to create heat sinks, which are essential components in electronics for dissipating heat and maintaining the optimal temperature of electronic devices. This precision stamping technique involves pressing a metal sheet into a specific shape, which is then used to efficiently transfer heat away from sensitive electronic components.

The Role of Heat Sinks in Electronics

Heat sinks play a crucial role in the functionality and longevity of electronic devices. By absorbing and dissipating excess heat generated by electronic components, heat sinks help prevent overheating and thermal damage. This is particularly important in devices that require high performance and reliability, such as computers, smartphones, and industrial machinery.

Benefits of Precision Stamped Heat Sinks

Precision stamped heat sinks offer several advantages over traditional heat sink manufacturing methods. These benefits include cost-effectiveness, high precision in design and production, efficient heat transfer properties, and the ability to create intricate and complex shapes that are tailored to specific electronic devices and applications.

Materials Used in Heat Sink Precision Stamping

Various materials can be used in the precision stamping of heat sinks, including aluminum, copper, and stainless steel. Each material has its own unique properties that affect the heat dissipation capabilities, weight, and cost of the heat sink. Aluminum is a popular choice due to its lightweight nature and excellent thermal conductivity.

The Precision Stamping Process

The precision stamping process for heat sinks involves the use of specialized equipment, such as stamping presses and dies, to form the metal sheet into the desired shape. This process requires precision and expertise to ensure that the heat sink meets the specific design requirements and performance standards.

Applications of Precision Stamped Heat Sinks

Precision stamped heat sinks are used in a wide range of electronic devices and industries, including computers, telecommunications equipment, automotive electronics, LED lighting, and power supplies. These heat sinks are designed to maximize heat dissipation and thermal management in demanding applications.

Customization and Design Flexibility

One of the key advantages of heat sink precision stamping is the ability to customize the design and shape of the heat sink according to the specific requirements of the electronic device. This flexibility allows manufacturers to create heat sinks that are optimized for performance, space constraints, and aesthetic considerations.

Efficiency and Energy Savings

By effectively dissipating heat away from electronic components, precision stamped heat sinks help improve the overall efficiency and energy savings of electronic devices. This is particularly important in devices that operate at high temperatures or have prolonged usage, as efficient thermal management can extend the lifespan of the device.

Quality Control and Reliability

Quality control is a critical aspect of heat sink precision stamping to ensure the consistency and reliability of the heat sinks produced. Manufacturers must adhere to strict quality standards and inspection processes to guarantee the performance and durability of the heat sinks, especially in applications where thermal management is essential.

Future Trends in Heat Sink Precision Stamping

As technology continues to advance, the demand for high-performance and compact electronic devices will drive the evolution of heat sink precision stamping techniques. Innovations in materials, designs, and manufacturing processes will further enhance the efficiency and effectiveness of heat sinks in addressing thermal challenges in modern electronics.

Quote Inquiry

contact us