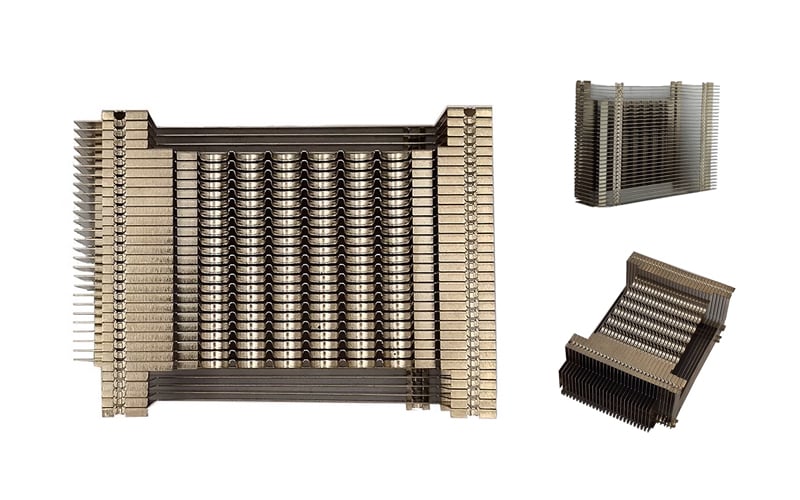

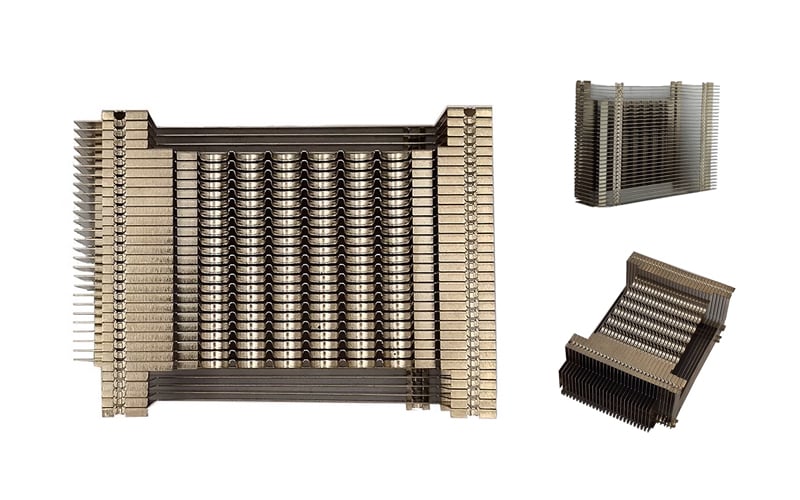

Efficient Production Process

When it comes to

heat sink mass production, an efficient production process is crucial. This process involves the use of automated machinery and techniques to produce a large number of heat sinks in a short amount of time. With the right equipment and skilled operators, companies can streamline their manufacturing process and increase their output.

Cost-Effectiveness

Mass production of heat sinks can result in significant cost savings for companies. By producing a large quantity of heat sinks at once, manufacturers can take advantage of economies of scale, which can lead to lower production costs per unit. This cost-effectiveness can ultimately benefit both the manufacturer and the end consumer.

High-Quality Products

Contrary to popular belief, mass production does not necessarily equate to lower quality products. In fact, with the right quality control measures in place, manufacturers can ensure that each heat sink produced meets the highest standards. By utilizing advanced testing methods and quality assurance protocols, companies can maintain consistent product quality throughout the production process.

Customization Options

While mass production typically involves producing a large quantity of identical products, companies can still offer customization options for heat sinks. By using flexible production techniques and advanced machinery, manufacturers can easily customize heat sinks to meet specific customer requirements. This level of customization can help companies attract a wider range of customers and cater to diverse market needs.

Rapid Turnaround Time

One of the key advantages of heat sink mass production is the ability to achieve rapid turnaround times. With an efficient production process in place, companies can quickly produce large quantities of heat sinks to meet tight deadlines. This quick turnaround time can be especially beneficial for companies working on time-sensitive projects or in fast-paced industries.

Scalability

Heat sink mass production offers scalability for manufacturers looking to expand their operations. As demand for heat sinks increases, companies can easily ramp up production to meet market needs. This scalability allows manufacturers to adapt to changing market conditions and scale their production levels accordingly.

Standardization of Products

Mass production of heat sinks allows for greater standardization of products. By using consistent production processes and materials, manufacturers can ensure that each heat sink meets the same specifications and quality standards. This standardization can help build brand trust and loyalty among customers who value reliability and consistency.

Reduced Lead Times

Another benefit of heat sink mass production is reduced lead times. With a streamlined production process in place, companies can minimize the time it takes to produce and deliver heat sinks to customers. This faster lead time can improve customer satisfaction and help companies gain a competitive edge in the market.

Environmental Sustainability

Mass production of heat sinks can also have positive environmental impacts. By optimizing production processes and reducing waste, companies can minimize their environmental footprint. Additionally, companies can explore sustainable materials and energy-efficient practices to further reduce their impact on the environment.

Market Competitiveness

In today's competitive market landscape, companies must stay ahead of the curve to remain competitive. Heat sink mass production allows companies to increase their production efficiency, reduce costs, and ultimately gain a competitive advantage. By leveraging the benefits of mass production, companies can position themselves as industry leaders and attract more customers.

Quote Inquiry

contact us