Efficiency and Cost-Effectiveness

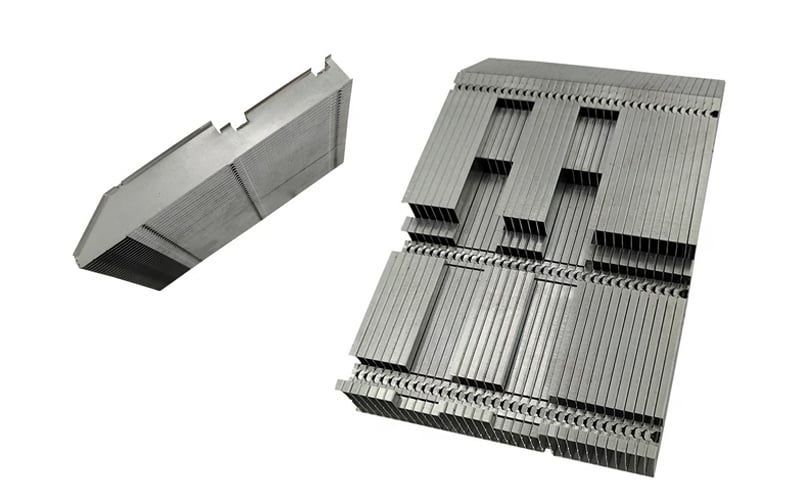

When it comes to heat sink production, the choice between stamping and die-casting can have a significant impact on efficiency and cost. Stamping is often preferred for high-volume manufacturing due to its quick production process and low labor costs. On the other hand, die casting is known for its ability to produce complex shapes with high precision, making it a popular choice for intricate designs.

Material Options and Customization

Stamping heat sinks are typically made from aluminum or copper sheets, which limits the range of materials that can be used. Die-casting, on the other hand, allows for a wider variety of materials, including aluminum, copper, and zinc. This flexibility in material selection enables greater customization options for die-cast heat sinks, making them ideal for specialized applications.

Heat Dissipation Performance

Both stamping and die-casting processes can create effective heat sinks, but die-cast heat sinks are generally considered to have better thermal conductivity. This is due to the higher density and purity of the materials used in die casting, which allows for improved heat dissipation. If optimal thermal performance is a priority, die-cast heat sinks may be the better choice.

Structural Integrity and Durability

Die-cast heat sinks are known for their superior structural integrity and durability compared to stamped heat sinks. The high pressure involved in the die-casting process results in a dense and uniform structure that can withstand harsh operating conditions. If longevity and robustness are key considerations, die-cast heat sinks are the way to go.

Lead Time and Production Volume

Stamping heat sinks are usually faster to produce than die-cast heat sinks, making them a preferred choice for projects with tight deadlines. However, die casting can be more cost-effective for larger production volumes due to its efficiency in mass production. Consider the lead time and production volume requirements of your project when choosing between stamping and die casting.

Surface Finish and Aesthetics

Die-cast heat sinks offer superior surface finish and aesthetic appeal compared to stamped heat sinks. The die-casting process allows for intricate designs, textures, and finishes that can enhance the overall look of the heat sink. If aesthetics are a priority for your project, die casting may be the better option.

Environmental Impact

In terms of environmental impact, both stamping and die casting have their pros and cons. Stamping generally produces less waste material and uses less energy, making it a more eco-friendly option. However, die casting can result in higher energy consumption and emissions due to the melting and casting of materials. Consider the environmental implications of each process before making a decision.

Tooling Costs and Maintenance

Die casting typically involves higher tooling costs upfront compared to stamping, as specialized molds are required for the casting process. However, once the molds are made, die casting can be more cost-effective for larger production runs. Stamping tools are generally less expensive to create and maintain, making stamping a more economical choice for smaller projects or prototypes.

Quality Control and Consistency

Die casting offers better control over the production process and ensures greater consistency in the final product compared to stamping. The use of precision molds in die casting results in heat sinks that are identical in shape and size, leading to improved quality control. If product consistency is a priority, die casting may be the preferred method.

Application-Specific Considerations

Ultimately, the choice between stamping and die casting for heat sink production will depend on the specific requirements of your application. Consider factors such as budget, project timeline, desired aesthetics, thermal performance, and environmental impact when making your decision. Both stamping and die casting have their strengths and weaknesses, so weigh your options carefully to determine the best fit for your needs.