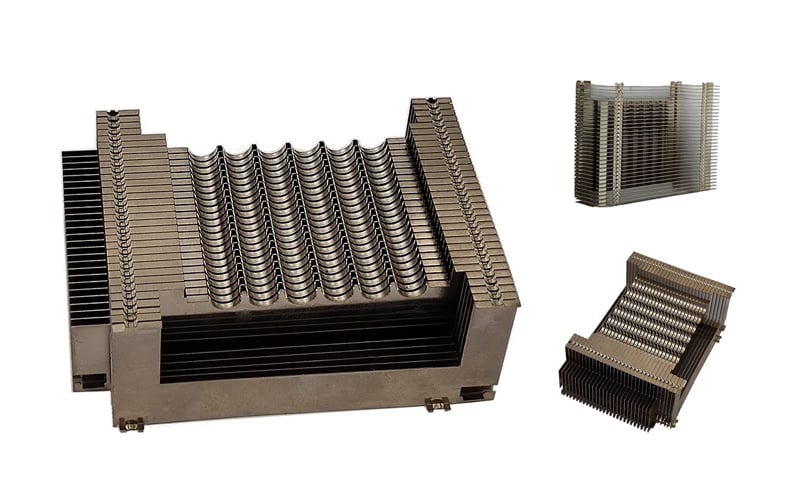

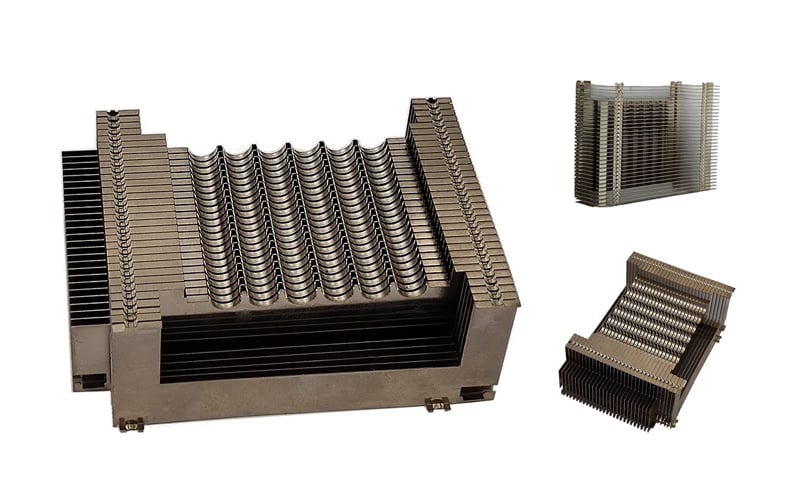

A stamping heat sink is a type of heat sink that is manufactured using a stamping process. This process involves shaping a metal sheet into the desired design through stamping and forming operations. Stamping heat sinks are commonly used in electronic devices to dissipate heat generated by electronic components.

Benefits of Stamping Heat Sinks

Stamping heat sinks offer several benefits compared to other types of heat sinks. They are cost-effective to manufacture due to the stamping process, which allows for high-volume production at a lower cost. Stamping heat sinks are also lightweight and have good thermal conductivity, making them an ideal choice for electronic devices that require efficient heat dissipation.

Types of Stamping Heat Sinks

There are various types of stamping heat sinks available, including passive and active heat sinks. Passive heat sinks rely on natural convection to dissipate heat, while active heat sinks use fans or other cooling mechanisms to enhance heat dissipation. Choosing the right type of stamping heat sink depends on factors such as the heat load and size constraints of the electronic device.

Materials Used in Stamping Heat Sinks

Stamping heat sinks are typically made from materials with high thermal conductivity, such as aluminum or copper. Aluminum is a popular choice for stamping heat sinks due to its lightweight and cost-effective nature, while copper offers superior thermal conductivity for efficient heat dissipation. The material choice will depend on the specific requirements of the electronic device.

Design Considerations for Stamping Heat Sinks

When designing a stamping heat sink, several factors need to be taken into account to ensure optimal performance. This includes the shape and size of the heat sink, as well as the placement of fins for increased surface area. The design should also accommodate airflow and ensure efficient heat transfer from the electronic components to the heat sink.

Installation of Stamping Heat Sinks

Proper installation of stamping heat sinks is crucial to their effectiveness in dissipating heat. The heat sink should be securely mounted onto the electronic component using thermal interface materials to maximize heat transfer. Care should be taken to avoid air gaps between the heat sink and the component, as this can hinder thermal conductivity.

Applications of Stamping Heat Sinks

Stamping heat sinks are used in a wide range of electronic devices, including computers, LED lights, and power supplies. They are essential for maintaining the temperature of electronic components within safe operating levels to prevent damage from overheating. Stamping heat sinks are also used in automotive electronics and telecommunications equipment for efficient heat dissipation.

Maintenance of Stamping Heat Sinks

Regular maintenance of stamping heat sinks is necessary to ensure optimal performance and prolong their lifespan. This includes cleaning the heat sink regularly to remove dust and debris that can obstruct airflow. Inspecting the heat sink for corrosion or damage is also important, as any defects can impact its thermal conductivity.

Future Trends in Stamping Heat Sinks

Advancements in technology are driving innovations in stamping heat sinks to meet the growing demand for more efficient cooling solutions in electronic devices. Future trends may include the development of new materials with enhanced thermal conductivity, as well as novel designs that improve heat dissipation capabilities. Stamping heat sinks are likely to continue playing a vital role in thermal management systems for electronic devices.

Conclusion

Stamping heat sinks are an essential component in the thermal management of electronic devices, providing efficient heat dissipation to prevent damage from overheating. Understanding the benefits, types, materials, and design considerations of stamping heat sinks is key to selecting the right heat sink for specific applications. With proper installation and maintenance, stamping heat sinks can help improve the performance and reliability of electronic devices.

Quote Inquiry

contact us