Understanding Skived Heat Sinks

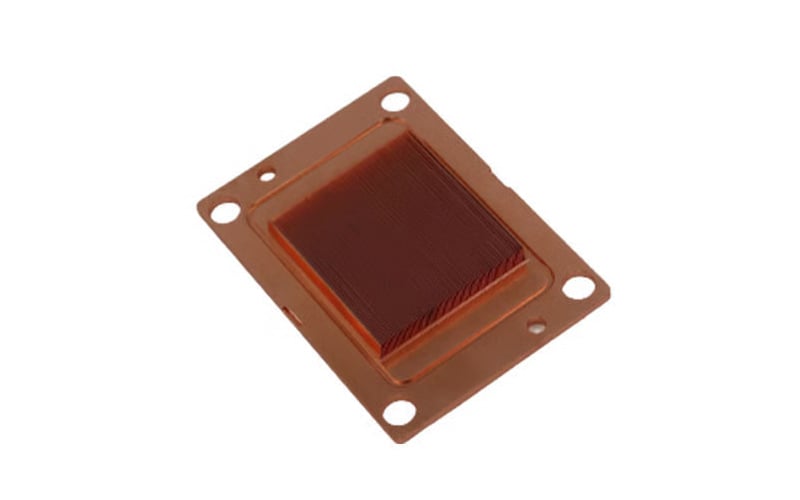

Skived heat sinks are a popular choice for thermal management in electronic devices. They are made by cutting thin fins from a solid block of aluminum or copper to create a high surface area for heat dissipation. This unique manufacturing process allows for better customization and optimizing the design for specific applications.

Benefits of Customized Skived Heat Sinks

Customized skived heat sinks offer several advantages over off-the-shelf options. They provide better heat dissipation, improved thermal performance, and increased reliability. By tailoring the design to fit the specific requirements of the application, you can achieve optimal cooling efficiency.

Factors to Consider When Customizing

When customizing skived heat sinks, there are several factors to keep in mind. These include the thermal requirements of the device, available space for the heat sink, airflow restrictions, and material selection. By considering these factors, you can create a heat sink that meets the specific needs of your application.

Design Considerations for Optimal Performance

To ensure optimal performance, it is important to consider the design of the skived heat sink. Factors such as fin geometry, base thickness, and overall size can impact the heat dissipation capabilities of the heat sink. By working with a knowledgeable manufacturer, you can optimize the design for the best results.

Customization Options for Skived Heat Sinks

There are several customization options available for skived heat sinks. These include different fin densities, heights, and shapes, as well as various surface treatments for improved thermal conductivity. By exploring these options, you can create a heat sink that is tailored to your specific needs.

Importance of Material Selection

The material choice plays a crucial role in the performance of a skived heat sink. Aluminum and copper are common materials used due to their high thermal conductivity. The selection of the material should be based on the thermal requirements, cost considerations, and compatibility with other components in the system.

Thermal Simulation and Analysis

Before finalizing the design of a customized skived heat sink, it is beneficial to conduct thermal simulation and analysis. This allows you to predict the heat dissipation capabilities of the heat sink and make any necessary adjustments to optimize its performance. Working with a skilled engineer can help ensure accurate results.

Testing and Validation Process

Once the customized skived heat sink has been manufactured, it is important to undergo testing and validation to ensure it meets the thermal requirements of the application. This may involve thermal cycling, heat transfer measurements, and thermal imaging to verify the performance of the heat sink.

Cost Considerations for Customization

While customized skived heat sinks offer many benefits, there are cost considerations to keep in mind. The complexity of the design, material selection, and manufacturing processes can all impact the overall cost of the heat sink. By working closely with a manufacturer, you can find a balance between performance and budget.

Choosing the Right Manufacturer

When considering skived heat sink customization, it is essential to choose the right manufacturer. Look for a company with experience in thermal management, a proven track record of producing high-quality heat sinks, and the ability to provide customized solutions. By partnering with the right manufacturer, you can ensure a successful outcome for your project.