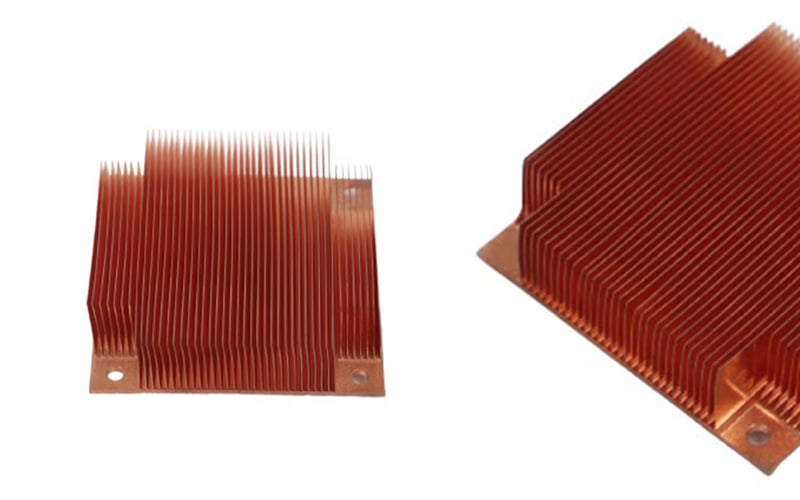

Skived heat sinks are premium cooling solutions that are designed to efficiently dissipate heat from electronic components in a wide range of applications. These heat sinks are typically made from aluminum or copper and feature a highly efficient design that maximizes surface area for better heat dissipation.

Consider Heat Sink Material

When selecting a skived heat sink for your project, it's important to consider the material of the heat sink. Aluminum heat sinks are lightweight and cost-effective, while copper heat sinks offer superior thermal conductivity. Choose the material that best suits your project's requirements.

Size and Dimensions Matter

The size and dimensions of the skived heat sink are crucial factors to consider when selecting the right heat sink for your project. Make sure to choose a heat sink that fits the available space in your application while providing sufficient cooling capacity.

Understanding Thermal Resistance

Thermal resistance is another important factor to consider when selecting a skived heat sink. Lower thermal resistance means better heat dissipation, so look for a heat sink with a low thermal resistance value to ensure optimal cooling performance.

Opt for Customization Opting for a customized skived heat sink can help ensure that the heat sink meets your project's specific requirements. Many manufacturers offer customization options for skived heat sinks, allowing you to tailor the heat sink to your application's needs.

Consider Fin Design

The fin design of a skived heat sink plays a significant role in its cooling efficiency. Choose a heat sink with a fin design that maximizes surface area for better heat dissipation, such as a pin fin or zipper fin design.

Factor in Weight and Cost

Weight and cost are also important factors to consider when selecting a skived heat sink for your project. Balance the cooling performance of the heat sink with its weight and cost to ensure that you choose a heat sink that meets your project's requirements.

Opt for Thermal Interface Material

Using a thermal interface material between the heat sink and the electronic component can help improve heat transfer and cooling efficiency. Consider using thermal pads or thermal paste to ensure optimal thermal conductivity.

Performance Testing and Evaluation

Before finalizing your decision, it's important to test and evaluate the performance of the skived heat sink in your application. Conduct thermal tests to ensure that the heat sink meets your cooling requirements and make any necessary adjustments.

Consult with Experts

If you're unsure about which skived heat sink is right for your project, don't hesitate to consult with heat sink experts. They can provide valuable insights and recommendations to help you select the best heat sink for your specific application.

Quote Inquiry

contact us