Efficient Heat Dissipation

Skived heat sink technology improves thermal performance by efficiently dissipating heat generated by electronic components. The design of the skived heat sink allows for better heat transfer compared to traditional heat sinks, resulting in lower operating temperatures and increased overall system performance.

Enhanced Surface Area

One of the key advantages of skived heat sink technology is its ability to create a larger surface area for heat dissipation. The skiving process involves cutting thin fins into the base of the heat sink, increasing the contact area with the surrounding air and maximizing heat transfer efficiency.

Improved Cooling Power

By increasing the surface area available for heat dissipation, skived heat sink technology significantly improves the cooling power of electronic devices. This allows for better thermal management, reduces the risk of overheating, and extends the lifespan of electronic components.

Customizable Designs

Skived heat sink technology offers the flexibility to create customized designs based on specific thermal requirements. Manufacturers can tailor the size, shape, and configuration of skived heat sinks to best suit the needs of their products, optimizing thermal performance in a wide range of applications.

Lightweight Construction

Despite their enhanced cooling capabilities, skived heat sinks are lightweight in construction. This makes them ideal for applications where weight is a concern, such as portable electronic devices or aerospace technology, without sacrificing thermal performance.

Cost-Effective Solutions

Skived heat sink technology provides a cost-effective solution for improving thermal performance in electronic systems. The efficient manufacturing process of skived heat sinks allows for mass production at a lower cost, making them an affordable option for businesses looking to enhance cooling efficiency.

Optimized Heat Transfer

The unique design of skived heat sink technology enables optimized heat transfer between electronic components and the surrounding environment. This results in more efficient cooling and reduced thermal resistance, ensuring that devices operate at optimal temperatures under various operating conditions.

Reduced Operating Costs

By enhancing thermal performance and improving heat dissipation, skived heat sink technology can help reduce overall operating costs for businesses. Lower operating temperatures can lead to decreased energy consumption, longer equipment lifespan, and fewer maintenance requirements.

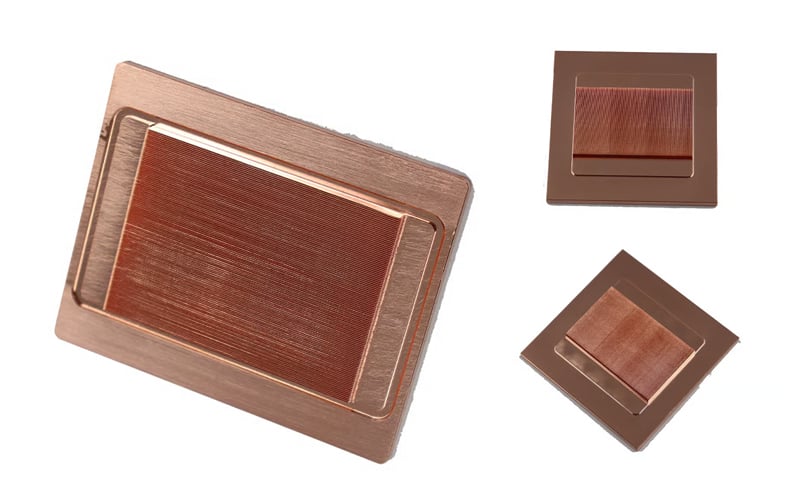

Compatibility with Various Materials

Skived heat sink technology is compatible with a wide range of materials, including aluminum, copper, and various alloys. This versatility allows manufacturers to choose the most suitable material for their specific application, further optimizing thermal performance and ensuring maximum efficiency.

Enhanced Performance in Compact Spaces

The compact design and efficient heat dissipation properties of skived heat sinks make them ideal for applications with limited space constraints. By maximizing heat transfer efficiency in a small footprint, skived heat sink technology improves thermal performance in compact electronic devices without compromising on cooling capabilities.