Introduction to Skived Heat Sinks

Skived heat sinks are essential components in electronic devices for heat dissipation. They are designed to transfer heat from the electronic components to the surrounding environment efficiently. Aluminum and copper are two popular materials used in skived heat sinks, each with its own characteristics and benefits.

Thermal Conductivity

One of the key differences between aluminum and copper skived heat sinks is their thermal conductivity. Copper has a higher thermal conductivity compared to aluminum, meaning it can transfer heat more effectively. This makes copper heat sinks more efficient in dissipating heat from electronic components.

Lightweight and Cost-Effective: Aluminum Heat Sinks

Aluminum heat sinks are lightweight and cost-effective compared to copper heat sinks. They are widely used in consumer electronics and computers due to their low cost and ease of manufacturing. However, aluminum has lower thermal conductivity than copper, which may affect its heat dissipation performance.

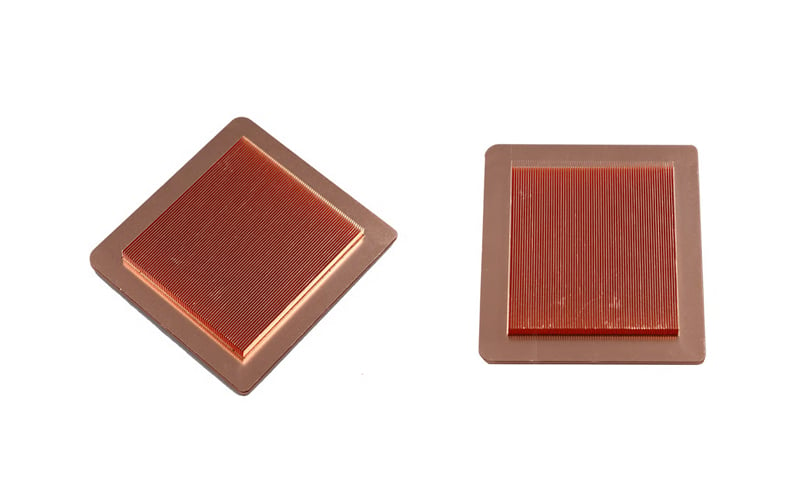

Durability and Performance: Copper Heat Sinks

Copper heat sinks are known for their durability and excellent thermal conductivity. They are ideal for applications where heat dissipation is critical, such as in high-performance computers and industrial equipment. Copper heat sinks are more expensive than aluminum heat sinks but offer superior heat dissipation performance.

Corrosion Resistance

Aluminum heat sinks are more prone to corrosion compared to copper heat sinks. Copper is a more durable and corrosion-resistant material, making it suitable for use in harsh environments or outdoor applications where exposure to moisture and other elements is a concern.

Customization and Design Flexibility

Both aluminum and copper heat sinks can be customized to fit specific design requirements and thermal management needs. However, aluminum is easier to machine and therefore offers more design flexibility compared to copper. Manufacturers can create intricate heat sink designs with aluminum for better thermal performance.

Environmental Impact

Copper is a natural resource that requires mining and extraction, leading to environmental concerns. On the other hand, aluminum is more abundant and recyclable, making it a more sustainable choice for heat sink materials. Choosing aluminum heat sinks can help reduce environmental impact and promote sustainability.

Application Specific Considerations

When choosing between aluminum and copper skived heat sinks, consider the specific application requirements. Copper heat sinks are best suited for high-power applications where thermal conductivity is critical, while aluminum heat sinks are suitable for lightweight and cost-effective solutions in consumer electronics.

Popularity and Market Trends

The choice between aluminum and copper skived heat sinks often comes down to a balance between cost, performance, and application needs. Copper heat sinks are preferred for high-performance applications, while aluminum heat sinks are popular in consumer electronics. Market trends may influence the choice of material for heat sink design.

Conclusion

In conclusion, both aluminum and copper skived heat sinks have their own advantages and disadvantages. Copper offers superior thermal conductivity and durability, while aluminum is lightweight and cost-effective. Consider the specific requirements of your application when choosing between aluminum and copper heat sinks for optimal heat dissipation performance.