Introduction

When it comes to cooling systems for various applications, two popular options are water cooling and liquid cold plates. Understanding the key differences between these two systems can help you make an informed decision on which one is best suited for your specific needs.

Efficiency and Performance

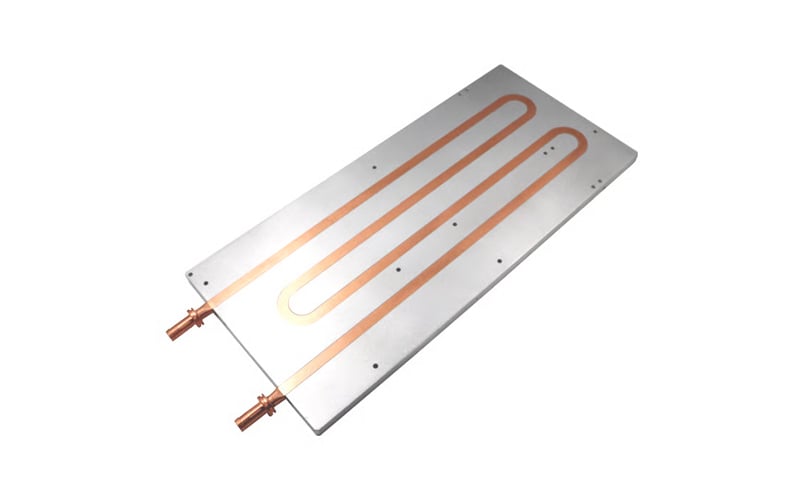

Water cooling systems typically rely on a pump to circulate water through a closed loop, absorbing heat from the source and dissipating it through a radiator. On the other hand, liquid cold plates come in direct contact with the heat source, providing more efficient heat transfer and enhanced performance compared to traditional water cooling systems.

Space and Installation

Water cooling systems require additional space for the radiator and tubing, which can be cumbersome and limit the overall flexibility in installation. Liquid cold plates, on the other hand, are compact and can be directly mounted onto the heat source, saving valuable space and simplifying the installation process.

Customization and Flexibility

Water cooling systems offer more customization options such as different radiator sizes, tubing materials, and cooling solutions. Liquid cold plates, while limited in customization, provide a more straightforward and hassle-free cooling solution for applications where space and simplicity are a priority.

Maintenance and Durability

Water cooling systems require regular maintenance to prevent algae growth, corrosion, and leakage issues. Liquid cold plates, due to their sealed design and direct contact with the heat source, offer a more durable and maintenance-free cooling solution that is ideal for long-term use in demanding environments.

Cooling Capacity and Heat Dissipation

Water cooling systems are better suited for applications that require high cooling capacities and efficient heat dissipation over a larger surface area. Liquid cold plates, on the other hand, excel in applications where localized cooling and precise temperature control are essential.

Cost and Investment

While water cooling systems may be more affordable upfront, the additional components and maintenance costs can add up over time. Liquid cold plates, although typically more expensive initially, offer a cost-effective solution in the long run due to their lower maintenance requirements and higher performance efficiency.

Noise and Operating Environment

Water cooling systems can generate more noise due to the operation of the pump and fans in the radiator. Liquid cold plates, being a passive cooling solution, operate silently and are ideal for applications where noise levels are a concern, such as in medical devices or recording studios.

Compatibility and Adaptability

Water cooling systems are versatile and can be adapted to different applications and industries with the right components and configurations. Liquid cold plates, while more specialized, are specifically designed for high-performance applications where efficient heat transfer is essential, such as in aerospace or automotive industries.

Environmental Impact

Water cooling systems consume electricity to operate the pump and fans, contributing to overall energy consumption. Liquid cold plates, being a passive cooling solution, have a lower environmental impact and are more energy-efficient, making them a suitable choice for eco-conscious applications.