What Are Sintered Heat Pipes?

Sintered heat pipes are advanced thermal management devices used to transfer heat away from electronic components in various applications. These pipes are made up of a sintered wick structure that allows for efficient heat transfer through capillary action.

Working Principle of Sintered Heat Pipes

Sintered heat pipes utilize the principle of evaporation and condensation to transfer heat. When the heat source vaporizes the working fluid in the wick structure, the vapor moves towards the cooler end of the pipe, where it condenses and releases heat.

Benefits of Sintered Heat Pipes

Sintered heat pipes offer several advantages over traditional heat transfer methods. These include high thermal conductivity, lightweight design, low thermal resistance, and the ability to operate in any orientation.

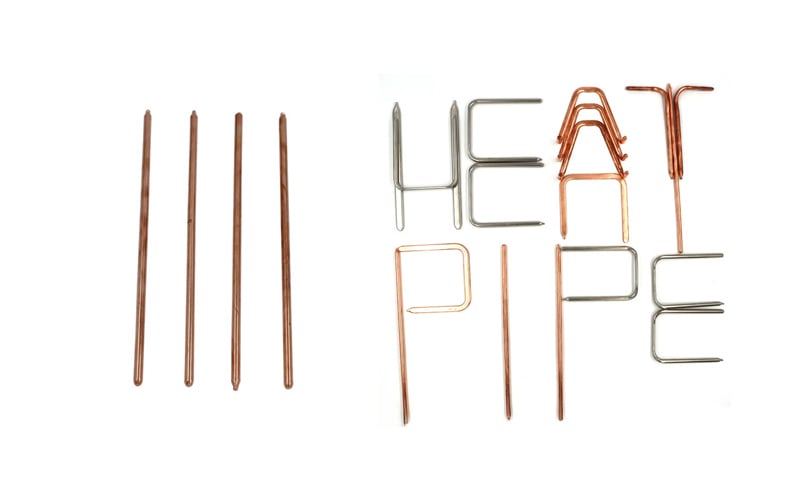

Materials Used in Sintered Heat Pipes

Sintered heat pipes are typically made from materials such as copper, aluminum, or stainless steel. The choice of material depends on the specific requirements of the application, such as thermal conductivity and corrosion resistance.

Applications of Sintered Heat Pipes

Sintered heat pipes are commonly used in electronic devices, LED lighting, aerospace systems, and renewable energy applications. These pipes are effective in dissipating heat from high-power electronic components and maintaining optimal operating temperatures.

Comparison with Other Heat Transfer Technologies

Sintered heat pipes offer several advantages over traditional heat transfer technologies such as heat sinks and fans. They provide more efficient heat dissipation, lower power consumption, noise-free operation, and longer lifespan.

Factors Affecting the Performance of Sintered Heat Pipes

Several factors can impact the performance of sintered heat pipes, including the choice of working fluid, wick structure design, operating temperature, and system orientation. It is essential to consider these factors during the design phase to optimize heat transfer efficiency.

Future Trends in Sintered Heat Pipe Technology

The field of sintered heat pipe technology is continuously evolving, with researchers exploring new materials, manufacturing techniques, and applications. Future advancements may lead to even higher thermal conductivity, improved reliability, and cost-effective solutions.

Environmental Impact of Sintered Heat Pipes

Sintered heat pipes offer a sustainable solution for thermal management, as they enable energy-efficient heat transfer without the need for additional cooling systems. By reducing energy consumption and lowering carbon emissions, sintered heat pipes contribute to environmental conservation.

Conclusion

In conclusion, sintered heat pipes are a vital component in modern thermal management systems, offering efficient heat transfer capabilities in various applications. By understanding The Science Behind Sintered Heat Pipes and their benefits, engineers and designers can implement these innovative technologies to optimize the performance of electronic devices and promote sustainability.