Introduction

If you are familiar with computer hardware, then you must have heard of the term heat sinks. Heat sinks are an essential component of any computer or electronic device to manage and dissipate heat generated by the electronic components. But, have you ever wondered why heat sinks have fins? In this article, we will explore the science behind this feature and how fins help in cooling down the electronic devices.

What are Heat Sinks?

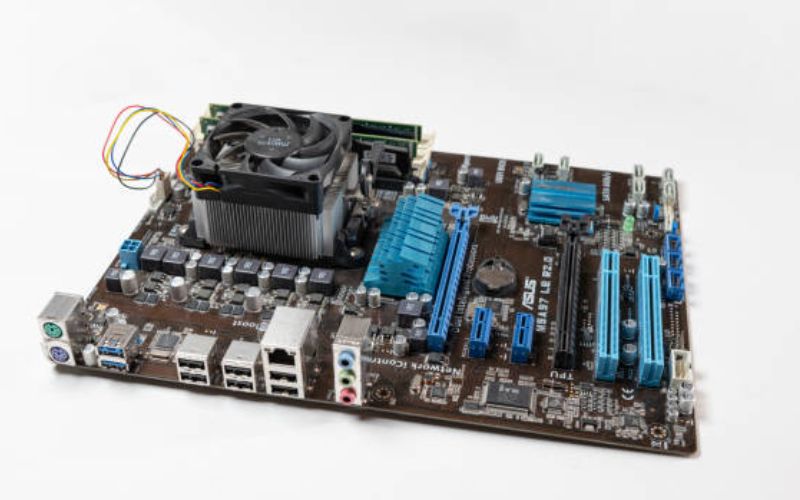

A heat sink is a passive cooling component in electronic devices that absorbs and dissipates the heat generated by electronic components like CPUs and GPUs. Heat sinks are made of materials like aluminum or copper with a large surface area to increase the heat dissipation rate.

Why Do Heat Sinks Need Fins?

The primary function of a heat sink is to reduce the temperature of the electronic component. The fins on the heat sink increase the surface area and hence increase the rate of heat dissipation. Heat is transferred from the electronic component to the heat sink and then to the surrounding air. The fins increase the surface area of the heat sink, which in turn increases the surface area available for heat dissipation.

How Do Fins on Heat Sinks Work?

The fins on heat sinks work by creating a larger surface area for heat dissipation. The surface area of the fins is exposed to the surrounding air, which allows the heat to escape from the heat sink faster. The fins also help to create turbulence in the air surrounding the heat sink, which further enhances the heat dissipation rate.

What is the Ideal Number of Fins for a Heat Sink?

The number of fins on a heat sink is a crucial factor in determining its cooling performance. The ideal number of fins depends on a variety of factors such as the size of the heat sink, the airflow rate, and the heat load. Generally, heat sinks with more fins have a higher cooling performance. However, having too many fins could also reduce the airflow and hinder heat dissipation.

How to Determine the Size and Number of Fins for a Heat Sink?

The size and number of fins on a heat sink depend on the thermal design power of the electronic components, the ambient temperature, and the airflow rate. The most common method to determine the size and number of fins is by using computational fluid dynamics (CFD) simulations or analytical models. These models help to optimize the heat sink design for maximum efficiency.

What Are the Types of Fins Used in Heat Sinks?

There are several types of fins used in heat sinks, including pin fins, straight fins, and louvered fins. Pin fins are thin and tall, whereas straight fins are thicker and shorter. Louvered fins have small tabs to enhance the heat transfer rates. The type of fins used depends on the specific application and the amount of heat generated by the electronic component.

What is the Effect of Fin Spacing on Heat Sink Efficiency?

The spacing between the fins on a heat sink plays a significant role in determining its cooling efficiency. If the spacing between the fins is too small, it could hinder the airflow, reducing the heat dissipation rate. On the other hand, if the spacing between the fins is too large, it could reduce the surface area available for heat dissipation, reducing the cooling efficiency.

Why Do Heat Sinks Have Different Fin Heights?

Heat sinks with different fin heights are used to optimize the cooling efficiency based on the thermal design power and the airflow rate. A heat sink with tall and thin fins is used for high thermal loads, whereas a heat sink with short and thick fins is used for low thermal loads. The height of the fins also affects the turbulence created in the airflow, affecting the heat dissipation rate.

What Role Does Material Play in Heat Sink Fins?

The material used in heat sink fins has a significant impact on its thermal performance. Materials like copper and aluminum are commonly used in heat sinks due to their excellent thermal conductivity. The surface finish of the fins also affects the heat dissipation rate. Smooth surface finishes enhance the heat transfer coefficient and improve the cooling efficiency.

Conclusion

In conclusion, the fins on a heat sink play a crucial role in enhancing its cooling efficiency. They increase the surface area of the heat sink, which, in turn, increases the surface area available for heat dissipation. The number, size, and spacing of the fins depend on various factors and should be optimized for maximum efficiency. Different types of fins are used based on the thermal load and the airflow rate. The material and surface finish of the fins also play a crucial role in improving the cooling efficiency of heat sinks.