What is the most common type of heat sink?

Heat sinks are essential components in many electronic devices, helping to dissipate heat and prevent overheating. There are various types of heat sinks available, but one particular type stands out as the most common. In this article, we will explore the most common type of heat sink and its features, applications, and advantages.

1. Passive Heat Sinks

Passive heat sinks are the most common type of heat sink used in electronic devices. They work by utilizing natural convection to transfer heat away from the heat source. These heat sinks consist of a baseplate, fins, and sometimes heat pipes. The baseplate is in direct contact with the heat source, while the fins increase the surface area for better heat dissipation.

2. Aluminum Heat Sinks

Aluminum heat sinks are widely used as the most common type of passive heat sink. Aluminum is an excellent thermal conductor and is lightweight, making it ideal for heat sink applications. These heat sinks are often extruded or stamped to create the desired shape and size. They are also cost-effective and readily available in the market.

3. Copper Heat Sinks

Copper heat sinks are another popular type of heat sink used in various electronic devices. Copper has a higher thermal conductivity than aluminum, allowing for more efficient heat transfer. However, copper is also more expensive and heavier than aluminum, making it suitable for specific applications where thermal performance is critical.

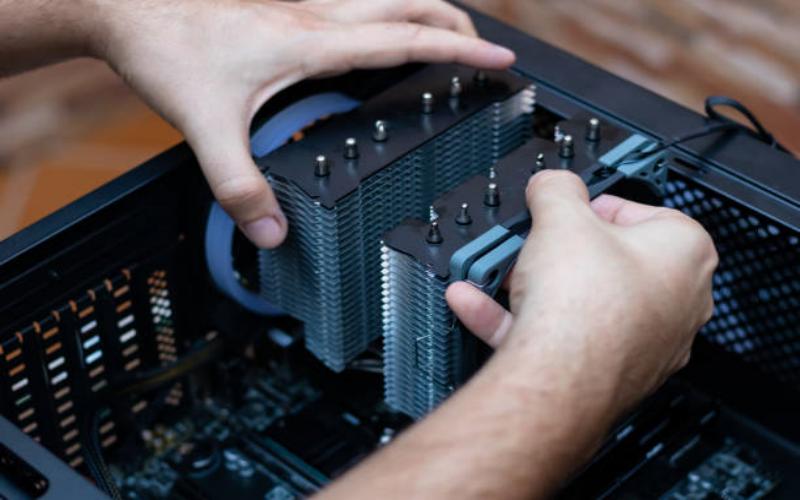

4. Active Heat Sinks

While passive heat sinks are the most common, active heat sinks are also widely used in certain applications. Active heat sinks incorporate additional components such as fans or pumps to enhance heat dissipation. These heat sinks are particularly useful in situations where passive cooling alone is insufficient, such as in high-power electronics or confined spaces.

5. Heat Pipe Heat Sinks

Heat pipe heat sinks are a type of passive heat sink that utilizes heat pipes to enhance heat transfer. Heat pipes are sealed copper tubes that contain a small amount of working fluid. These heat sinks are highly efficient in transporting heat from the heat source to the fins, where it can be dissipated more effectively. Heat pipe heat sinks are commonly used in applications requiring high-performance cooling.

6. Pin Fin Heat Sinks

Pin fin heat sinks are another variation of passive heat sinks, featuring a densely packed array of pins instead of traditional fins. The pins increase the surface area for heat dissipation, allowing for efficient cooling in compact spaces. Pin fin heat sinks are commonly found in small electronic devices such as laptops and smartphones.

7. Plate Fin Heat Sinks

Plate fin heat sinks are characterized by a flat baseplate with fins attached vertically. These heat sinks offer good thermal performance and are often used in applications where space is limited. Plate fin heat sinks are commonly used in computer CPUs, LED lighting, and power electronics.

8. Bonded Fin Heat Sinks

Bonded fin heat sinks are constructed by bonding individual fins onto a baseplate. This type of heat sink offers excellent thermal performance and is particularly useful in applications where high power dissipation is required. Bonded fin heat sinks are commonly found in industrial equipment, power amplifiers, and high-performance computing systems.

9. Stacked Fin Heat Sinks

Stacked fin heat sinks feature multiple layers of fins stacked on top of each other, increasing the surface area for improved heat dissipation. This design allows for efficient cooling in applications with limited space. Stacked fin heat sinks are commonly used in server racks, telecommunications equipment, and automotive electronics.

10. Extruded Heat Sinks

Extruded heat sinks are manufactured by forcing heated aluminum or copper through a die to create the desired shape and profile. They are cost-effective and widely used in various applications. Extruded heat sinks can be customized to meet specific thermal requirements, making them a versatile choice for many electronic devices.