The Evolution of Cooling Technology: Introducing Liquid Cold Plates

In the ever-advancing world of technology, heat management plays a crucial role in ensuring optimal performance and longevity of electronic components. Over the years, various cooling solutions have emerged, and one of the most efficient and effective methods is the liquid cooling system. In this article, we will delve into the fascinating world of liquid cold plates and explore their benefits, applications, and working principles.

Understanding Liquid Cold Plates: The Basics

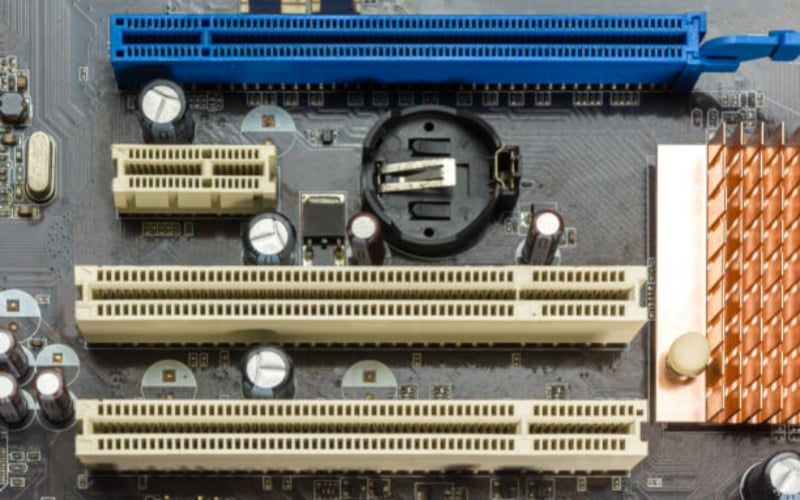

Liquid cold plates, also known as liquid-cooled plates or liquid heat sinks, are heat transfer devices that utilize liquid as a cooling medium to dissipate heat generated by electronic components. These plates are typically made of a thermally conductive material, such as copper or aluminum, and feature a network of channels or microchannels that allow the liquid to flow through.

The Working Principle of Liquid Cold Plates

The working principle of liquid cold plates is based on the concept of forced convective heat transfer. The liquid, usually water or a specialized coolant, flows through the channels or microchannels, coming into direct contact with the heat-generating components. As the liquid absorbs heat, it undergoes a phase change, converting from a liquid to a vapor or gas. This phase change process effectively carries away the heat from the components, preventing them from overheating.

The Advantages of Liquid Cold Plates

Liquid cold plates offer several significant advantages over traditional air cooling methods. Firstly, they provide superior heat dissipation capabilities, allowing for efficient cooling of high-power electronic devices. Additionally, liquid cooling systems are significantly quieter than their air-cooled counterparts, making them ideal for noise-sensitive environments. Furthermore, liquid cold plates eliminate the need for bulky heat sinks and fans, resulting in a more compact and streamlined design.

Applications of Liquid Cold Plates

Liquid cold plates find applications in a wide range of industries where efficient heat management is critical. One of the most prominent applications is in the field of power electronics, where high-power devices such as inverters and power modules require effective cooling. They are also extensively used in the aerospace industry to cool avionics systems and in the automotive industry to cool electric vehicle batteries and power electronics.

The Importance of Material Selection

The choice of material for liquid cold plates is crucial in ensuring optimum performance and reliability. Copper and aluminum are the most commonly used materials due to their excellent thermal conductivity. Copper offers superior heat transfer capabilities but comes at a higher cost, while aluminum provides a cost-effective solution without compromising significantly on performance. The selection of the material depends on factors such as cost, thermal requirements, and application-specific considerations.

Comparing Liquid Cold Plates with Other Cooling Solutions

When it comes to cooling electronic components, several alternatives to liquid cold plates exist, including air cooling, heat pipes, and thermoelectric coolers. While each solution has its own advantages and limitations, liquid cold plates offer superior thermal performance, efficiency, and noise reduction compared to air cooling. Heat pipes and thermoelectric coolers, on the other hand, are more suitable for specific applications where space constraints or precise temperature control is required.

Design Considerations for Liquid Cold Plates

Designing an effective liquid cold plate involves careful consideration of various factors. The layout and arrangement of the channels or microchannels play a critical role in maximizing heat transfer efficiency. The choice of coolant, flow rate, and pressure drop across the plate also impact the overall performance. Additionally, factors such as sealing methods, corrosion resistance, and compatibility with the electronic components must be taken into account during the design process.

The Future of Liquid Cold Plates

As technology continues to advance, liquid cold plates are expected to play an increasingly significant role in heat management. With the rise of emerging technologies such as electric vehicles, data centers, and high-performance computing, the demand for efficient cooling solutions will continue to grow. Researchers and engineers are constantly exploring new materials, designs, and manufacturing techniques to further enhance the performance and reliability of liquid cold plates.

In Conclusion

Liquid cold plates are a cutting-edge cooling solution that offers superior heat dissipation capabilities, noise reduction, and compact design. They find applications in a wide range of industries and are particularly crucial for cooling high-power electronic devices. With ongoing advancements in technology, liquid cold plates are poised to revolutionize the way we manage heat in the ever-evolving world of electronics.