What is liquid cold plate? - A Comprehensive Guide

Introduction

As technology continues to advance, the need for efficient cooling solutions becomes increasingly important. One such solution that has gained popularity in recent years is the liquid cold plate. This article aims to provide a comprehensive guide to understanding what a liquid cold plate is, how it works, and its various applications.

1. Understanding Liquid Cold Plate Technology

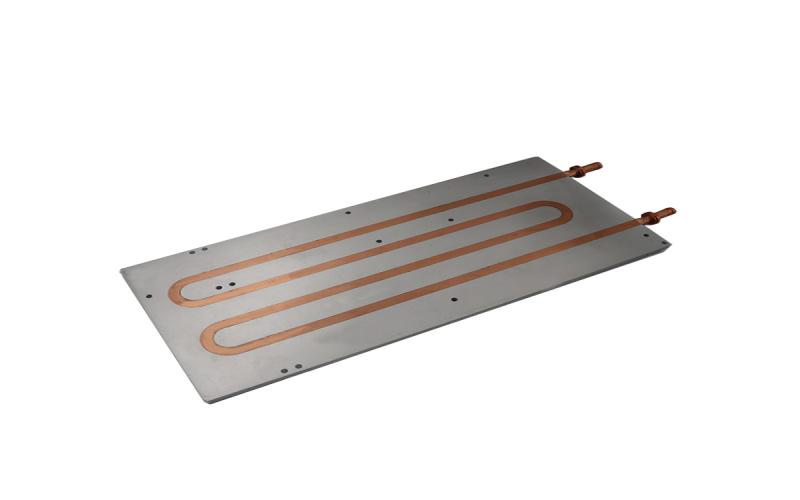

Liquid cold plates are heat exchangers that utilize liquid as a cooling medium to dissipate heat generated by electronic components. These plates are typically made of highly conductive materials such as copper or aluminum, which allows for efficient heat transfer.

Within the cold plate, there are intricate channels or tubes through which the cooling liquid flows. These channels come in contact with the heat source, absorbing the generated heat. The heated liquid then carries the heat away from the source and transfers it to a secondary cooling system, such as a radiator or heat sink.

2. How Liquid Cold Plates Work

Liquid cold plates work on the principle of conduction and convection. When the heat from electronic components is transferred to the cold plate, the liquid inside the channels absorbs the heat through conduction. The heated liquid then moves away, creating space for cooler liquid to come in contact with the heat source.

As the liquid absorbs heat, it undergoes a phase change, such as boiling or evaporation, depending on the cooling system's design. This phase change helps to enhance the cooling efficiency by absorbing a significant amount of heat energy. The cooled liquid then circulates back to the heat source, repeating the cycle.

3. Advantages of Liquid Cold Plates

Efficient Heat Dissipation: Liquid cold plates offer higher thermal conductivity compared to traditional air-cooling methods, enabling more efficient heat dissipation.

Uniform Cooling: The liquid flowing through the channels ensures uniform cooling across the entire surface of the cold plate, preventing hotspots and temperature imbalances.

Compact Design: Liquid cold plates can be designed to fit specific applications, allowing for compact and space-saving cooling solutions.

Noisy-Free Operation: Unlike fans used in air-cooling systems, liquid cold plates operate silently, making them suitable for noise-sensitive environments.

4. Applications of Liquid Cold Plates

Data Centers: Liquid cooling solutions, including liquid cold plates, are being increasingly adopted in data centers to manage the high heat loads generated by servers and other equipment.

Electric Vehicles (EVs): Liquid cold plates are used in EVs to cool high-power components, such as batteries and power electronics, ensuring optimal performance and extended lifespan.

Medical Equipment: Liquid cold plates find applications in medical equipment, such as MRI machines and laser systems, where precise temperature control is crucial.

Industrial Machinery: Liquid cold plates are utilized in various industrial machinery, including laser cutting machines, welding equipment, and power supplies, to maintain stable operating temperatures.

5. Considerations for Liquid Cold Plate Selection

Thermal Performance: The thermal performance of a liquid cold plate depends on factors such as material conductivity, channel design, and flow rate. It is essential to evaluate these parameters to ensure efficient heat dissipation.

Compatibility: Liquid cold plates should be compatible with the cooling liquid used, ensuring no corrosion or detrimental effects on the system.

Cost and Maintenance: Consider the overall cost of the liquid cold plate system, including installation, maintenance, and replacement, to determine its feasibility for a specific application.

6. Future Trends in Liquid Cold Plate Technology

As technology advances, liquid cold plate technology is also expected to evolve. Some key trends to watch out for include:

Enhanced Materials: Researchers are exploring new materials with even higher thermal conductivity to improve the overall efficiency of liquid cold plates.

Integration with Other Cooling Technologies: Liquid cold plates may be integrated with other cooling technologies, such as phase change materials or thermoelectric coolers, to achieve even better thermal management.

7. Conclusion

Liquid cold plates offer an effective and efficient cooling solution for various applications, ranging from data centers to electric vehicles. By utilizing the principles of conduction and convection, these plates ensure uniform heat dissipation and prevent temperature imbalances. As the demand for advanced cooling solutions grows, liquid cold plate technology continues to evolve, promising even better thermal management capabilities in the future.