The Basics of Heat Pipe Heat Sink

Heat pipe heat sinks are advanced cooling devices that are widely used in various industries to dissipate heat from electronic components. These innovative solutions have revolutionized the thermal management of high-power electronic devices, ensuring optimal performance and reliability. In this article, we will explore the concept of heat pipe heat sinks and their key advantages.

How Does a Heat Pipe Heat Sink Work?

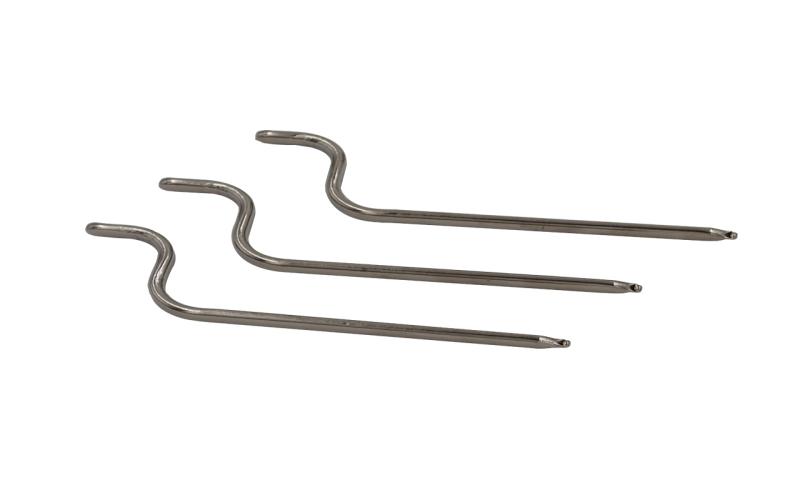

A heat pipe heat sink consists of a sealed copper or aluminum pipe filled with a small amount of working fluid, typically water, ammonia, or a low-boiling-point liquid. The heat pipe is attached to the heat source, such as a CPU or power transistor, and a heat sink is attached to the other end of the pipe. When the heat source generates heat, the working fluid in the heat pipe evaporates and forms a vapor. This vapor travels to the cooler end of the pipe, where it condenses back into a liquid and releases the heat to the ambient environment. The liquid then returns to the hot end through capillary action, completing the heat transfer cycle.

Advantages of Heat Pipe Heat Sinks

Heat pipe heat sinks offer several advantages over traditional cooling methods:

High Thermal Conductivity

Heat pipes have extremely high thermal conductivity, typically several thousand times higher than copper. This enables efficient heat transfer over long distances and allows for effective cooling of hot electronic components.

Passive Cooling

Unlike active cooling methods that require fans or pumps, heat pipe heat sinks operate on passive cooling principles. This eliminates the need for additional power consumption and reduces the risk of mechanical failure.

Uniform Temperature Distribution

Heat pipe heat sinks distribute heat evenly across their surfaces, ensuring uniform temperature distribution and preventing hotspots. This is crucial for maintaining the reliability and longevity of electronic devices.

Compact and Lightweight

Heat pipe heat sinks are compact and lightweight compared to traditional cooling solutions. Their small form factor makes them ideal for space-constrained applications, such as laptops, mobile devices, and aerospace systems.

No Moving Parts

Since heat pipe heat sinks operate without any moving parts, they are highly reliable and have a longer lifespan compared to mechanical cooling solutions. This makes them suitable for harsh operating conditions and environments with vibrations or shocks.

No Noise or Vibration

As heat pipe heat sinks do not require fans or pumps, they generate no noise or vibration. This makes them ideal for noise-sensitive applications, such as audio equipment, medical devices, and laboratories.

Wide Temperature Range

Heat pipe heat sinks can operate over a wide temperature range, from cryogenic temperatures to several hundred degrees Celsius. This versatility makes them suitable for various industries, including electronics, automotive, aerospace, and renewable energy.

Easy Installation

Installing a heat pipe heat sink is relatively simple and straightforward. They can be easily integrated into existing systems or designed into new product developments, providing efficient thermal management with minimal effort.

Cost-Effective Solution

Despite their advanced technology, heat pipe heat sinks offer a cost-effective thermal management solution. Their high efficiency and reliability translate into energy savings, reduced maintenance costs, and improved overall system performance.

The Future of Heat Pipe Heat Sinks

As electronic devices continue to become more powerful and compact, the demand for efficient thermal management solutions like heat pipe heat sinks will only increase. Ongoing research and development aim to further enhance their performance, reduce manufacturing costs, and explore novel applications in emerging industries.