What Is a Liquid Cold Plate?

A liquid cold plate is a device used to cool electronics by transferring heat away from the source through a liquid coolant. These plates are made of a special material that conducts heat well and are typically designed with channels to allow the coolant to flow through.

How Does a Liquid Cold Plate Work?

When the electronic component heats up, the liquid coolant absorbs the heat through the cold plate. The coolant then circulates through the plate, carrying the heat away as it flows. This process continues until the heat is dissipated, allowing the electronic component to operate at a safe temperature.

Benefits of Using a Liquid Cold Plate

Liquid cold plates offer many advantages over traditional air cooling methods. They provide more efficient heat transfer, lower operating temperatures, and reduced noise levels. Additionally, liquid cooling allows for more precise temperature control, which can help extend the life of electronic components.

Types of Liquid Cold Plates

There are several types of liquid cold plates available, including tube cold plates, flat tube cold plates, and box cold plates. Each type has its own unique design and cooling capabilities, allowing users to choose the best option for their specific cooling needs.

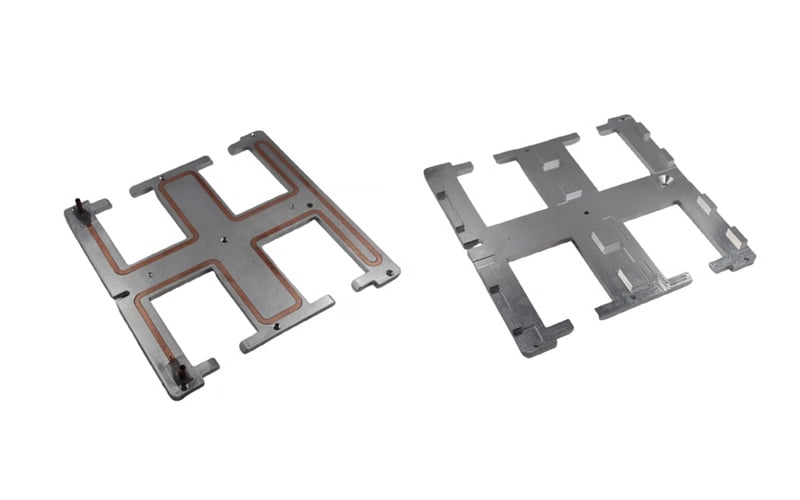

Materials Used in Liquid Cold Plates

Liquid cold plates are typically made of materials such as copper, aluminum, or stainless steel. These materials have high thermal conductivity, allowing them to efficiently transfer heat away from the electronic component. Some cold plates may also have a coating or plating to improve corrosion resistance.

Applications of Liquid Cold Plates

Liquid cold plates are commonly used in various industries, including telecommunications, medical devices, and power electronics. They are ideal for cooling high-power components, such as CPUs, GPUs, and power supplies, where traditional air cooling may not be sufficient.

Installation and Maintenance of Liquid Cold Plates

Proper installation and maintenance are crucial to the performance of liquid cold plates. It is important to ensure a tight connection between the cold plate and the electronic component to maximize heat transfer. Regular cleaning and inspection are also recommended to prevent clogs and ensure efficient cooling.

Considerations When Choosing a Liquid Cold Plate

When selecting a liquid cold plate, factors such as cooling capacity, size, material, and coolant type should be taken into consideration. It is essential to choose a cold plate that is compatible with the specific requirements of the electronic component to ensure optimal performance.

Future Trends in Liquid Cooling Technology

As technology continues to advance, liquid cooling solutions are evolving to meet the demands of increasingly powerful electronic components. Innovations such as microchannel cold plates and hybrid cooling systems are being developed to enhance cooling efficiency and reliability.

Conclusion

Liquid cold plates are an effective cooling solution for a wide range of electronic applications. By understanding how they work and the benefits they offer, users can make informed decisions when selecting a cold plate for their cooling needs. With proper maintenance and consideration of key factors, liquid cold plates can help extend the life and improve the performance of electronic components.