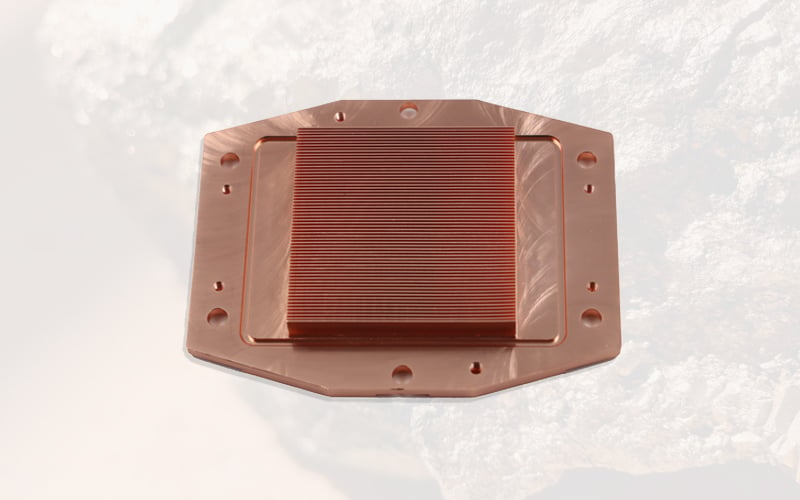

What is a Copper Skived Heat Sink?

A copper skived heat sink is a type of heat sink that is made from copper and is commonly used to cool electronic devices. It is designed to efficiently dissipate heat and prevent the overheating of electronic components, which can lead to reduced performance and even permanent damage.

The Importance of Heat Dissipation

Heat dissipation is a crucial aspect of electronic device design. As electronic components become smaller and more powerful, they generate more heat. If this heat is not effectively dissipated, it can lead to a decrease in performance, shortened lifespan, and even complete failure of the device.

How Does a Copper Skived Heat Sink Work?

A copper skived heat sink works by utilizing the high thermal conductivity of copper to transfer heat away from the electronic component. The heat sink is typically attached to the component using thermal interface materials, such as thermal pads or thermal paste, to ensure effective heat transfer.

The Skived Fin Design

The term "skived" refers to the manufacturing process used to create the fins of the heat sink. Skiving involves cutting thin fins from a solid piece of copper using a specialized machine. This process allows for the creation of high-density fins with precise dimensions, maximizing the surface area available for heat dissipation.

The Advantages of Copper

Copper is an excellent material for heat sinks due to its high thermal conductivity, which allows it to quickly transfer heat away from the electronic component. It also has good corrosion resistance and is readily available, making it a cost-effective choice for heat sink applications.

Applications of Copper Skived Heat Sinks

Copper-skived heat sinks are widely used in various industries and applications, including:

- Computer and server cooling

- LED lighting

- Power electronics

- Telecommunications

Factors to Consider in Heat Sink Selection

When choosing a copper skived heat sink, several factors need to be considered, including:

- Power dissipation requirements

- Available space for the heat sink

- Thermal resistance

- Weight and size limitations

- Cost

The Role of Thermal Design

Proper thermal design is crucial for the effective use of a copper skived heat sink. It involves considering the overall system's thermal requirements, selecting appropriate heat sink dimensions and materials, and ensuring proper attachment and airflow for optimal heat dissipation.

Other Types of Heat Sinks

In addition to copper skived heat sinks, there are other types of heat sinks available, including:

- Aluminum extrusion heat sinks

- Heat pipes

- Vapor chamber heat sinks

- Stacked fin heat sinks

Conclusion

A copper skived heat sink is an essential component in the thermal management of electronic devices. Its ability to efficiently dissipate heat helps to ensure the reliable and optimal performance of electronic components. By understanding the role and advantages of copper skived heat sinks, designers and engineers can make informed decisions when it comes to heat sink selection and thermal design.