Introduction

Heat sinks are an indispensable component in electronic devices. They are responsible for dissipating heat generated by electronic components such as CPUs and graphics cards to the environment. Heat sinks are commonly made from copper and aluminum materials. Both of them have unique properties that make them suitable for various applications. But which one is better? In this article, we will explore the differences between copper and aluminum heat sinks, and which one is better for specific use cases.

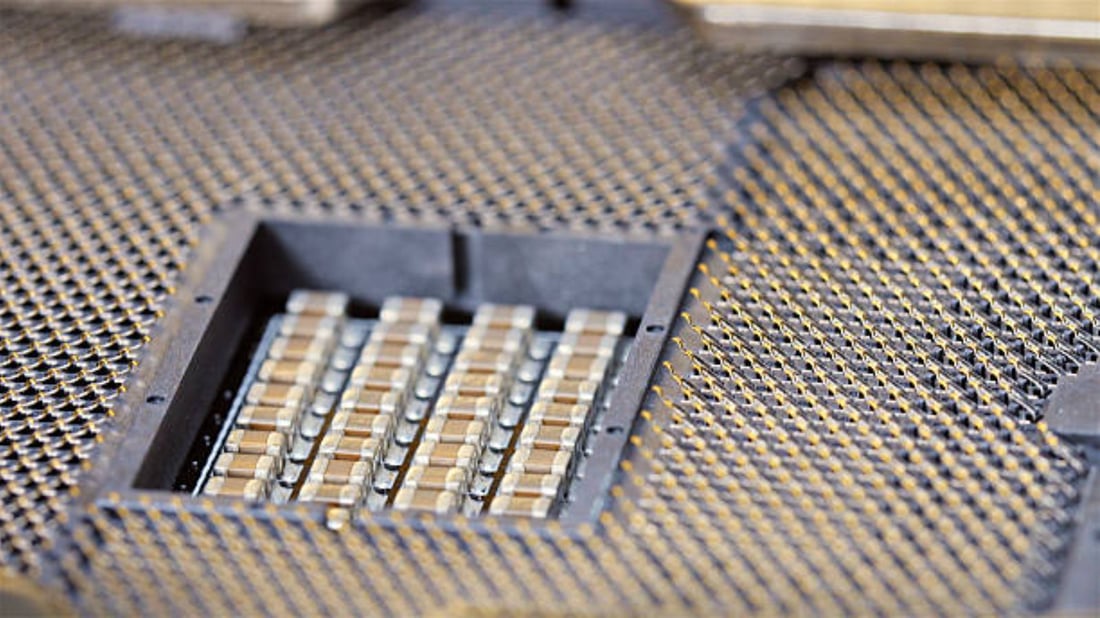

Copper Heat Sinks

Copper is an excellent heat conductor, second only to silver. Copper heat sinks can dissipate heat quickly, which makes them suitable for high-performance applications. Additionally, copper has a high melting point, which enables copper heat sinks to withstand high temperatures without deteriorating. Copper heat sinks, however, are more expensive than aluminum heat sinks. Copper also tends to oxidize and corrode over time, while aluminum does not. Therefore, copper heat sinks require regular maintenance to retain optimal performance.

Aluminum Heat Sinks

Aluminum is a lightweight and cost-effective material used in heat sink construction. Aluminum heat sinks offer excellent thermal conductivity and are suitable for applications where heat dissipation is a concern. One of the main advantages of aluminum heat sinks is their ability to withstand oxidation and corrosion. This ability makes them ideal for industrial environments or outdoor applications where exposure to the elements is a potential issue. However, aluminum has a lower melting point than copper, which means that it's not suitable for high-temperature applications.

Performance Comparison

When it comes to performance, copper has the edge over aluminum. Copper heat sinks have a higher thermal conductivity, which means they can transfer heat more quickly than aluminum heat sinks. As a result, copper heat sinks are suitable for high-performance applications that generate a lot of heat. However, aluminum heat sinks have a larger surface area than copper heat sinks for the same size, making them better at dissipating heat through natural convection.

Copper vs. Aluminum: Weight

Aluminum heat sinks are lighter in weight than copper heat sinks for the same size. This makes them suitable for applications where weight is a concern, such as in aerospace and automotive industries. Copper heat sinks, on the other hand, are denser than aluminum heat sinks, which makes them heavier. This property makes copper heat sinks less suitable for applications where weight is a concern.

Copper vs. Aluminum: Cost

Copper is more expensive than aluminum, which makes copper heat sinks more expensive than aluminum heat sinks. However, copper has a longer lifespan than aluminum and requires less maintenance. This property makes copper heat sinks a more cost-effective solution in the long run despite their high purchase price. If, however, the budget is a concern, aluminum heat sinks are a better solution.

Copper vs. Aluminum: Corrosion

Copper corrodes over time and requires regular maintenance to maintain optimal performance. Aluminum, on the other hand, does not corrode as easily as copper, making it a better solution for applications where exposure to the elements is a potential issue. If the heat sink is located in a corrosive environment, such as near the sea, then aluminum heat sinks are a better solution.

Copper vs. Aluminum: Manufacturing

Both copper and aluminum heat sinks can be manufactured using similar techniques such as extrusion, forging, and die casting. Copper heat sinks, however, require more energy to manufacture than aluminum heat sinks, which makes them more expensive to produce. Furthermore, copper has a lower ductility than aluminum, which means that it's harder to shape copper heat sinks using techniques such as extrusion. Aluminum, on the other hand, is more ductile and easier to shape, making it a better solution for complex geometries.

Copper vs. Aluminum: Environmental Impact

Both copper and aluminum are recyclable materials, which means that they have a low environmental impact. However, copper requires more energy to recycle than aluminum, which makes aluminum a better solution from an environmental perspective, especially if the heat sink is used in a disposable application.

Conclusion

Both copper and aluminum heat sinks have their unique properties that make them suitable for various applications. Copper heat sinks offer better thermal conductivity and are suitable for high-performance applications, but they are more expensive and require regular maintenance. Aluminum heat sinks, on the other hand, are lightweight, cost-effective, and offer excellent corrosion resistance, making them suitable for outdoor or corrosive environments. Choosing between copper and aluminum heat sinks depends on the specific application and performance requirements.