The Different Types of Liquid Cold Plates Explained

Cold plates are essential components in various cooling systems, allowing for efficient heat transfer between electronic components and a cooling fluid. They are commonly used in applications such as power electronics, high-performance computing, and electric vehicles. In this article, we will explore the different types of liquid cold plates available in the market and their unique features and advantages.

1. Passive Cold Plates

Passive cold plates, also known as simple cold plates, rely solely on natural convection to dissipate heat. They are typically made of aluminum or copper and have a series of channels or fins to increase the surface area for heat transfer. Passive cold plates are an economical choice for low to medium power applications where noise and size are not major concerns.

2. Active Cold Plates

Active cold plates incorporate additional features to enhance heat dissipation, such as fans or pumps. These cold plates are suitable for high-power applications where forced convection is necessary to achieve optimal cooling performance. Active cold plates offer higher heat transfer rates and can handle larger thermal loads compared to passive cold plates.

3. Brazed Cold Plates

Brazed cold plates are manufactured by bonding multiple layers of metal together using a brazing process. This creates a strong and leak-free construction, ensuring excellent thermal performance. Brazed cold plates are commonly used in high-power applications where reliability and efficiency are crucial.

4. Press-Fit Cold Plates

Press-fit cold plates are designed for easy installation and removal without the need for complex fasteners or adhesives. They feature a unique design that allows the cold plate to be pressed into place, creating a secure and reliable thermal interface between the cold plate and the heat source. Press-fit cold plates are ideal for applications that require frequent maintenance or testing.

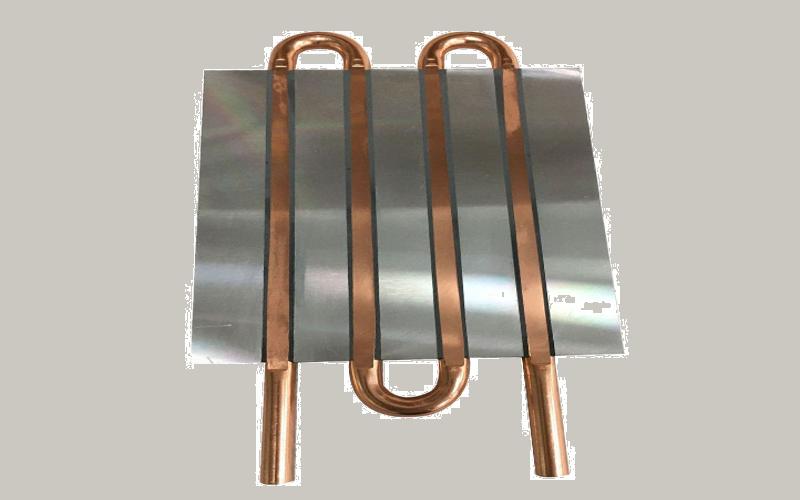

5. Tube-in-Plate Cold Plates

Tube-in-plate cold plates consist of a series of small tubes embedded within a metal plate. These tubes allow for the flow of cooling fluid, maximizing the contact area with the heat source. Tube-in-plate cold plates offer efficient heat transfer and are commonly used in applications where space is limited.

6. Micro-Channel Cold Plates

Micro-channel cold plates utilize a large number of small channels to enhance heat transfer. These channels are typically less than a millimeter in size, allowing for high surface area contact with the cooling fluid. Micro-channel cold plates offer excellent thermal performance and are often used in high-power density applications.

7. Customizable Cold Plates

Customizable cold plates are designed to meet specific requirements and can be tailored to fit unique cooling needs. They can be customized in terms of shape, size, material, and additional features. Customizable cold plates are often used in industries where standard off-the-shelf options do not provide an optimal cooling solution.

8. Direct Liquid Cooling Plates

Direct liquid cooling plates are designed to directly cool specific components, such as processors or graphics cards, by bringing the cooling fluid in direct contact with the heat source. This method ensures efficient heat transfer and allows for precise temperature control. Direct liquid cooling plates are commonly used in high-performance computing systems.

9. Hybrid Cold Plates

Hybrid cold plates combine different cooling technologies to achieve optimal performance. For example, a hybrid cold plate may incorporate both passive and active cooling elements or combine micro-channel and tube-in-plate designs. Hybrid cold plates are versatile and can be customized to meet specific cooling requirements.

10. Aluminum Nitride Cold Plates

Aluminum nitride cold plates are specifically designed for applications that require high thermal conductivity and electrical insulation. Aluminum nitride has excellent thermal properties and can withstand high operating temperatures. These cold plates are commonly used in power electronics and high-power LED applications.