The Versatility of Aluminum Extrusions Heat Sinks

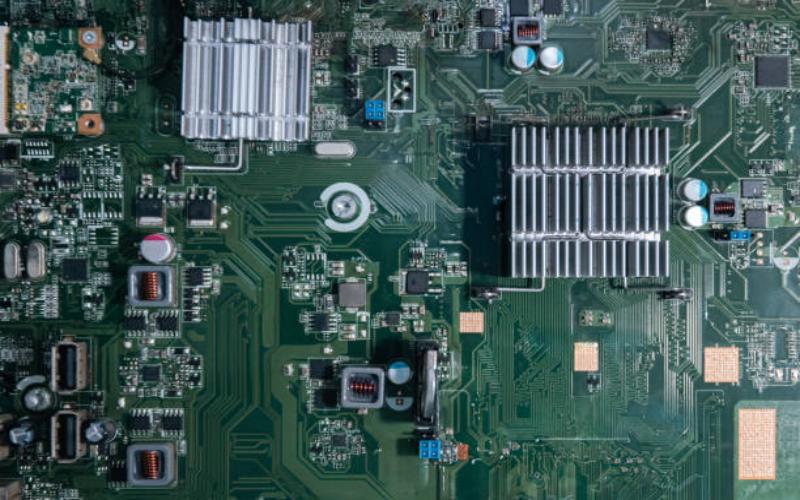

Aluminum extrusions heat sinks are an integral component in various industries where efficient heat dissipation is crucial. These heat sinks provide a cost-effective and reliable solution for managing heat generated by electronic devices, ensuring their optimal performance and longevity. In this article, we will delve into the different applications and benefits of aluminum extrusions heat sinks, highlighting their significance in today's technology-driven world.

1. Electronics Industry

The electronics industry heavily relies on aluminum extrusions heat sinks to dissipate the heat generated by electronic components. Whether it's in computers, smartphones, televisions, or other electronic devices, heat sinks play a vital role in preventing overheating and ensuring the smooth operation of these devices. They are often designed with various fins and shapes to maximize the surface area for better heat dissipation.

2. LED Lighting

LED lighting has gained significant popularity due to its energy efficiency and long lifespan. However, LEDs also generate heat during operation, which can affect their performance and lifespan. Aluminum extrusions heat sinks help dissipate the heat generated by LEDs, ensuring they remain within the optimal temperature range. These heat sinks are often integrated into the design of LED lighting fixtures, allowing for efficient cooling and improved longevity of the LEDs.

3. Automotive Industry

The automotive industry relies on aluminum extrusions heat sinks for managing the heat generated by various components, including engines, power electronics, and lighting systems. Heat sinks in vehicles help maintain the optimal temperature for these components, ensuring their reliable performance and longevity. They are designed to withstand harsh environmental conditions, vibrations, and other challenges specific to the automotive industry.

4. Industrial Machinery

In industrial machinery and equipment, heat sinks are used to dissipate heat from power electronics, motor drives, and other heat-generating components. These heat sinks prevent overheating, which can lead to system failures and costly downtime. Aluminum extrusions heat sinks are preferred in industrial applications due to their excellent thermal conductivity, lightweight nature, and ease of customization.

5. Renewable Energy Systems

Renewable energy systems, such as solar panels and wind turbines, often generate heat during their operation. This heat can impact the efficiency and overall performance of these systems. Aluminum extrusions heat sinks are used to dissipate the excess heat and maintain the optimal operating temperature for improved energy conversion efficiency. These heat sinks are designed to withstand outdoor conditions and provide long-term reliability.

6. Telecommunications

Telecommunication equipment, such as routers, switches, and servers, generate significant heat due to continuous operation and data processing. Heat sinks are essential in these applications to prevent overheating and ensure the reliable functioning of the equipment. Aluminum extrusions heat sinks offer high thermal conductivity and efficient heat dissipation, making them an ideal choice for telecommunications devices.

7. Medical Equipment

Medical equipment, ranging from diagnostic devices to MRI machines, often generate substantial heat during their operation. Heat sinks are used in these applications to maintain the optimal temperature and prevent any potential damage to delicate components. Aluminum extrusions heat sinks provide efficient cooling and enable medical equipment to operate reliably for extended periods.

8. Aerospace and Aviation

In the aerospace and aviation industries, heat management is critical to ensure the safety and performance of aircraft components. Aluminum extrusions heat sinks are extensively used in avionics, radar systems, and electronic control units to dissipate the heat generated by these critical components. The lightweight and durable nature of aluminum makes it a suitable material for aerospace applications.

9. Power Electronics

Power electronics, such as inverters and converters, generate significant heat during their operation. Efficient heat dissipation is crucial to maintain the performance and reliability of these components. Aluminum extrusions heat sinks offer excellent thermal conductivity and can be customized to fit the specific requirements of power electronic systems, making them an ideal choice for heat management in this field.

10. Consumer Appliances

Consumer appliances, including refrigerators, air conditioners, and gaming consoles, often generate heat during their operation. Heat sinks are employed in these appliances to prevent overheating and ensure their efficient performance. Aluminum extrusions heat sinks provide an effective and cost-efficient solution for heat management in consumer appliances, contributing to their reliability and longevity.